5 mrw size, 6 mrw limit, Mrw size – Eppendorf AF2200 Plate Reader User Manual

Page 43: Mrw limit

Operation

Eppendorf

®

PlateReader AF2200

English (EN)

43

6.4.5

MRW size

The MRW size determines the number of points to be measured in a well. Depending on the device and the

microplate type, a 1 x 1 area with a maximum of 15 x 15 points can be selected for the size. The diameter of

the individual measuring points is the same as the theoretically calculated diameter of the light beam in the

focus (see table).

Therefore, the MRW type shown in the software is only a schematic overview of the measuring pattern. The

pattern may vary when measuring real samples and the overlapping of the individual measuring points may

deviate slightly from the displayed pattern. Therefore, we recommend optimizing the parameters for

several measurements per well for each new application.

6.4.6

MRW limit

In addition to the size and type, a limit function allows the user to select a specific distance between the

light beam and the wall of the well (distance in μm). As previously mentioned, the software gives only a

schematic overview of the measuring pattern. The limit is calculated from the theoretical beam diameter of

the device. However, when measuring liquid samples, the diameter of the light beam is affected by the type

and volume of the liquid in the well.

The plate type (e.g., material of the microplate base) also affects the properties of the light beam. As a

result, the theoretical limit displayed in the software may not be identical to the actual limit when

measuring a real sample. Therefore, we highly recommend optimizing the parameters for several

measurements per well for each new application. Make sure that the selected limit guarantees an adequate

distance between the light beam and the wall of the microplate.

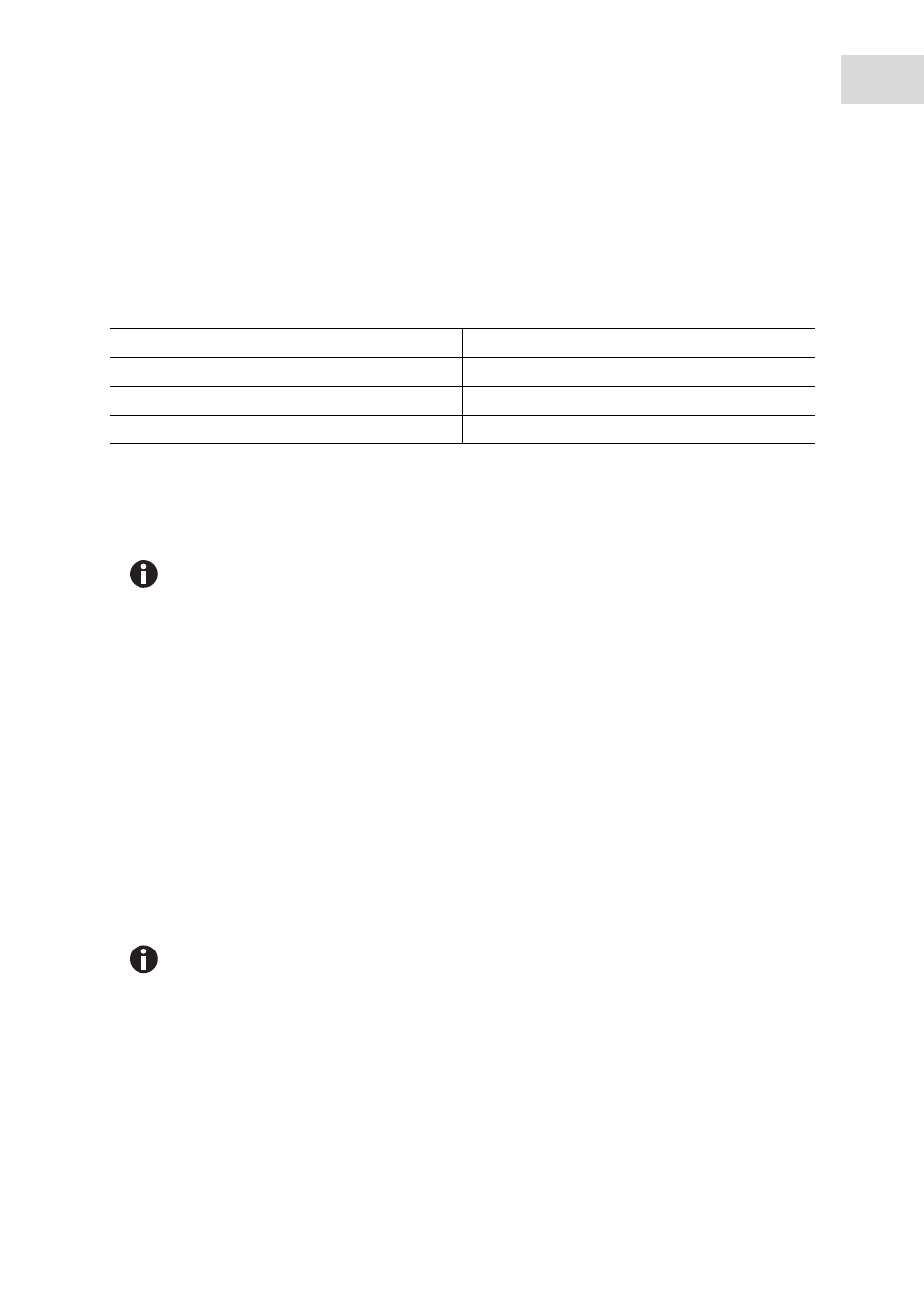

Measuring mode

Upper fluorescence intensity

2 mm

Lower fluorescence intensity

2 mm

Absorbance (microplate optics)

0.5 mm

Only a schematic overview of the measuring pattern is shown in the software. Therefore, the

parameters for several measurements per well must be optimized for every new application.

Make sure that the selected limit is sufficient to prevent an overlap between the light beam

and the wall of the microplate.

A value that is too low for the limit can lead to incorrect measuring results due to overlaps

between the light beam and the well wall.