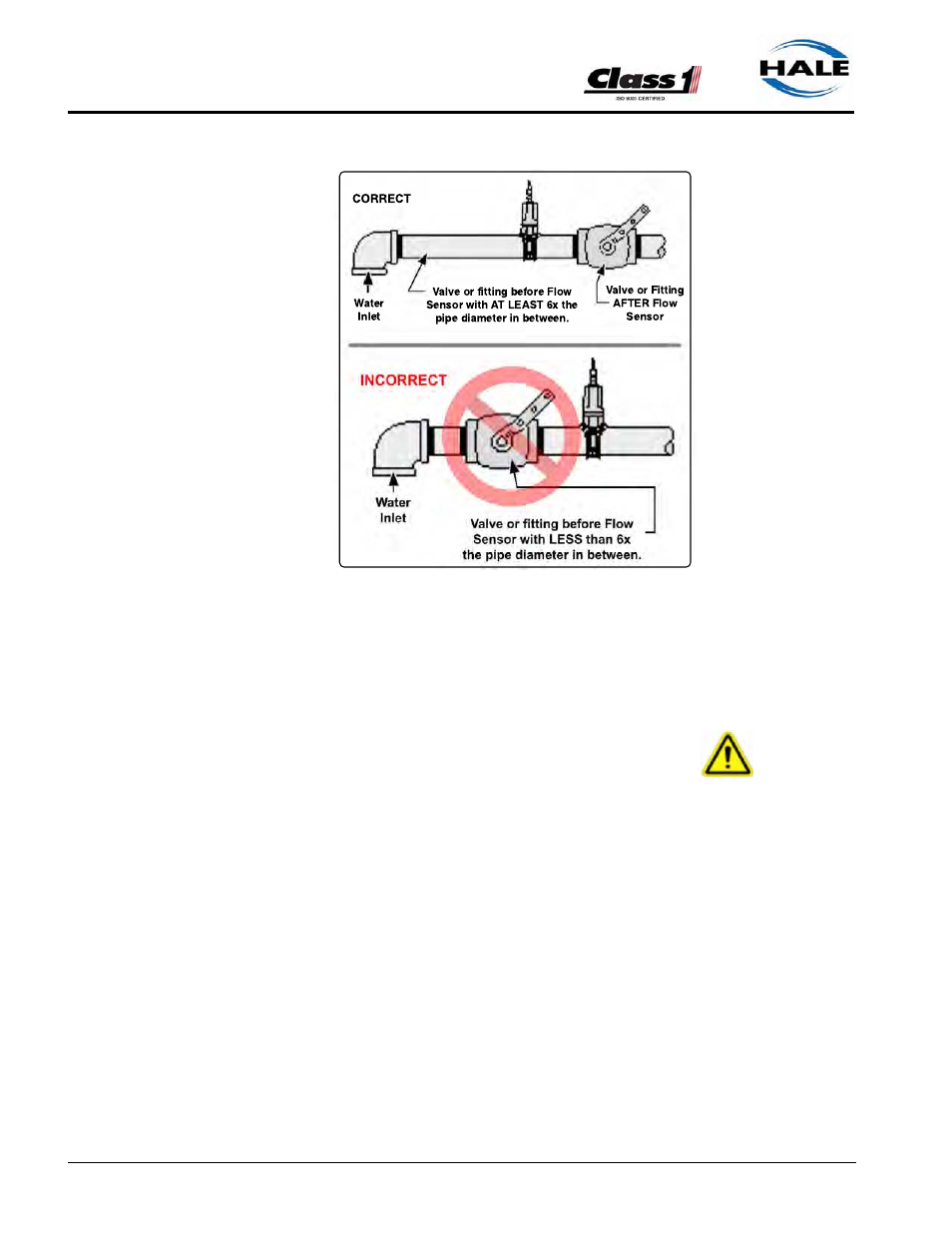

Figure 3-12: flow sensor placement, Saddle clamp installation – Hale FoamLogix 6.5 User Manual

Page 64

❑ Installer Installation

64

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

The downstream piping

length is not as critical,

but there must be a short

length of straight pipe

with no fittings or valves

immediately after the flow

sensor paddle wheel.

Two to three times the

pipe diameter is recom-

mended.

Do not mount a flow sen-

sor directly after an

elbow or valve. Valves

create severe turbulence

when they are “gated.”

Saddle Clamp Installation

(See Figure 3-13: “Flow Sensor/Saddle Clamp Installation,” on page 65.)

IMPORTANT !

THE PADDLE WHEEL SHOULD BE INSTALLED AS CLOSE TO UPRIGHT AS

POSSIBLE WITHIN THE RANGE SHOWN FIGURE 3-9: “FLOW SENSOR TEE

POSITION RANGE” ON PAGE 62. FOR PROPER OPERATION DO NOT LET

THE FLOW SENSOR ROTATE MORE THAN 85° IN EITHER DIRECTION.

Installation of the Paddle Wheel Flow Sensor using a saddle clamp requires

a 1.385”/1.390” (35/35.3mm) bored hole in the pipe. A minimum of six (6)

times the pipe diameter of straight run pipe without any fittings is necessary

prior to the position of this hole.

The flow sensor requires a spacer and eight stainless steel internal hex

head screws. These are supplied with the sensor.

Four 6-32 x 1/2” screws attach the spacer to the saddle clamp mount, and

four 6-32 x 3/4” screws with lock washers attach the paddle wheel to the

spacer.

Figure 3-12: Flow Sensor Placement