Table 3-10: pipe size vs. minimum straight run – Hale FoamLogix 6.5 User Manual

Page 63

63

FoamLogix 3.3 / 5.0 / 6.5 Installer / Operations Manual

p/n: 029-0021-68-0

Ins ta lle r Ins ta lla tion

❑

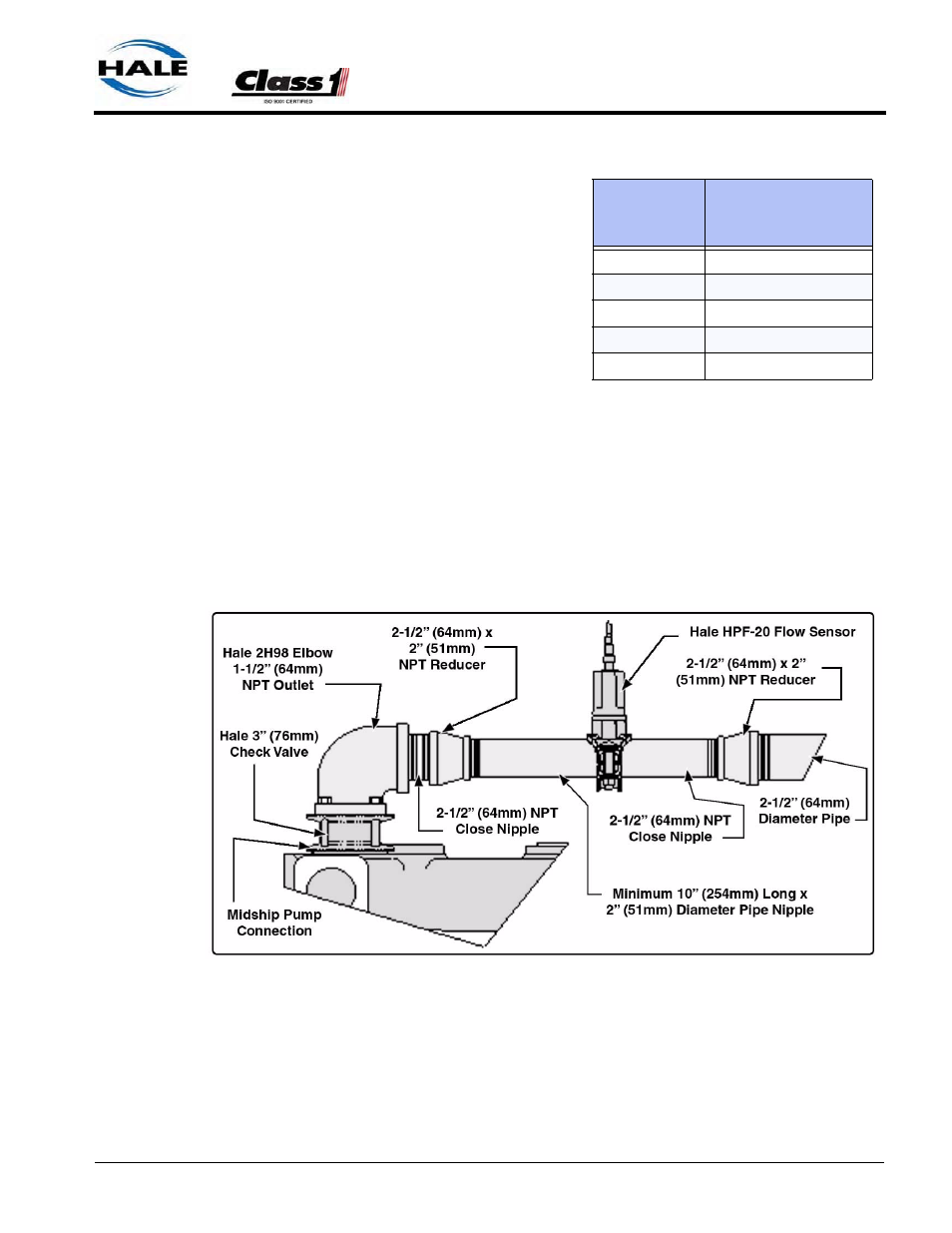

Refer to Table 3-10: “Pipe Size vs.

Minimum Straight Run” for pipe

size. Selecting the next smaller

pipe permits reducing the straight

pipe run the required distance prior

to the flow sensor paddle wheel.

In the short length of reduced pipe

pressure loss is minimal and there

is minimal pressure loss through

elbows and fittings. (See Figure 3-

11: “Typical Reduced Size Sensor

Piping Arrangement.”)

Excessive turbulence in the flow sensor may produce unstable and inaccu-

rate flow readings. The length of straight pipe prior to the flow sensor must

be sufficient to reduce any turbulence in the pipe.

The following guidelines help attain the best readings, and maintain Hale

FoamLogix system accuracy.

Figure 3-11: Typical Reduced Size Sensor Piping Arrangement

A minimum of 6 times the pipe diameter of straight run pipe without any fit-

tings is necessary prior to the flow sensor paddle wheel. (See Figure 3-12:

“Flow Sensor Placement,” on page 64.)

Pipe Sizes

Minimum

Recommended Straight

Run Pipe

1-1/2" (38mm)

9" (229mm)

2" (51mm)

12" (305mm)

2-1/2" (64mm)

15" (381mm)

3" (76mm)

18" (457mm)

4" (102mm)

24" (610mm)

Table 3-10: Pipe Size vs. Minimum

Straight Run