6 fitting, 6fitting – Festo Модуль перемещения HSP User Manual

Page 38

HSP−...−AP/A S

Festo HSP−...−AP/AS 0508a English

38

S

Slowly pressurize the complete system.

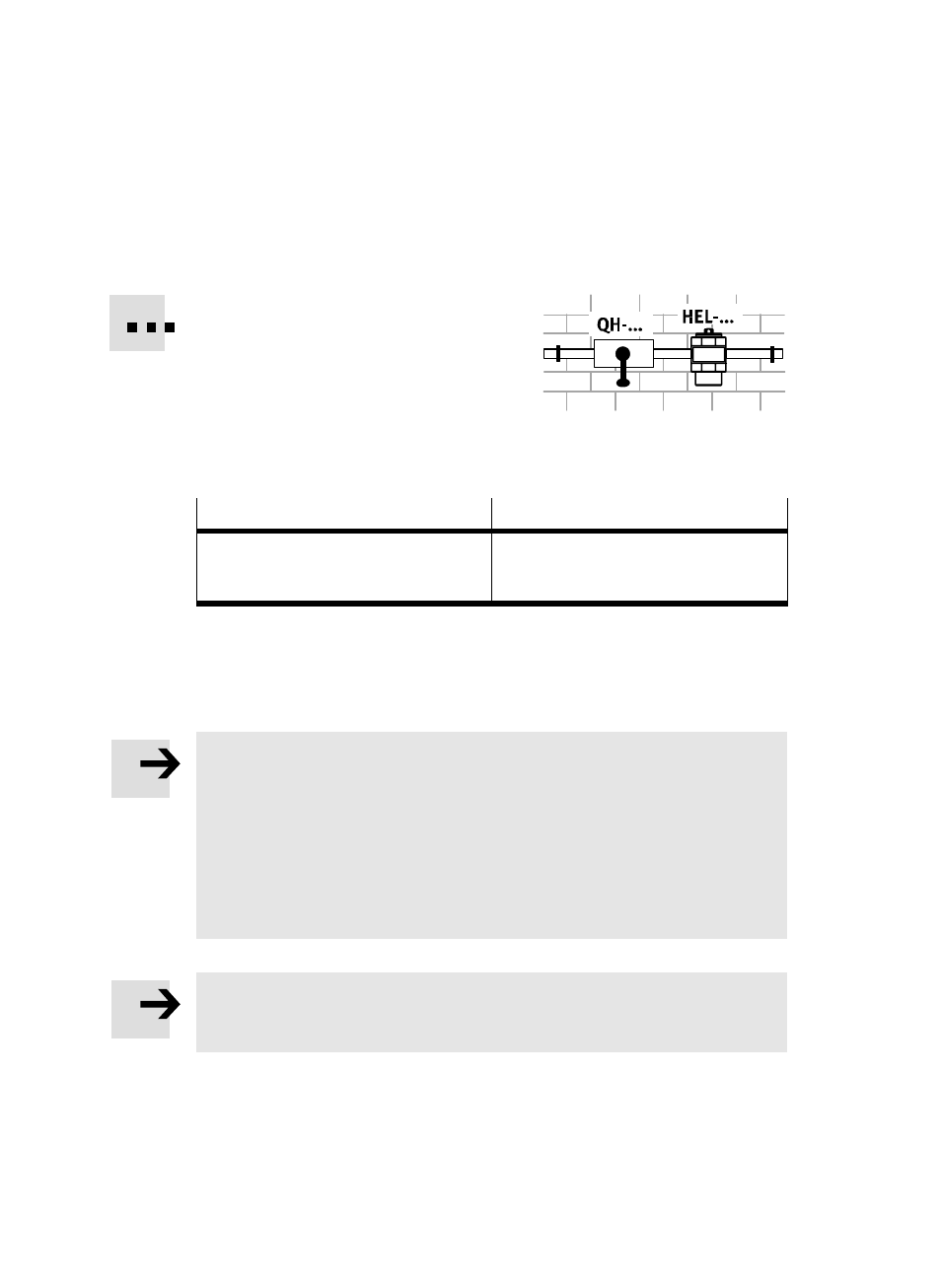

To do this use start−up valve type HEL−... /

HEM−...Ă.

S

Check to see if the following are

necessary:

a compensation reservoir type VZS−...

a non−return valve type HGL−...

This will reduce fluctuations in the

pressure.

In this way you can prevent the work load

from sliding down if there is a sudden drop

in pressure.

6

Fitting

Please note

Note especially the following when fitting all the components:

Ĉ Screw connections must be fitted free of offset and mechanical tension.

Ĉ Screws must be fitted accurately (otherwise threads will be damaged).

Ĉ The specified torques must be observed.

Ĉ Contact surfaces must be clean (avoid leakage and contact faults).

Observe also the installation instructions supplied with modules and compoĆ

nents ordered at a later stage.

Please note

For the type HSP−...−...WR/WL: Please observe the warnings and instructions in

the operating instruction for the BWR−/BWL−HSP−...

Fig. 6