Red Lion PAX2D User Manual

Model pax2d – 1/8 din digital input panel meter, Description, Safety summary

1

3.80 (96.52)

(49.53)

(2.54)

(44.45)

3.60 (91.44)

4.14 (105)

1.95

0.10

1.75

1

3

2

4

z

COUNT, DUAL COUNTER WITH MATH FUNCTIONS

z

RATE, DUAL RATE WITH MATH FUNCTIONS

z

SLAVE DISPLAY

z

UNIVERSAL AC/DC POWER SUPPLY

z

6 / 9 DIGIT DUAL LINE/TRI-COLOR DISPLAY WITH 0.71" & 0.35"

DIGITS

z

10 POINT RATE SCALING FOR NON-LINEAR PROCESSES

z

PROGRAMMABLE UNITS DISPLAY

z

BUS CAPABILITIES; DEVICENET, MODBUS, AND PROFIBUS-DP

z

BUILT-IN USB PROGRAMMING PORT ENABLING UNIT

CONFIGURATION WITH CRIMSON PROGRAMMING SOFTWARE

z

NEMA 4X/IP65 SEALED FRONT BEZEL

DESCRIPTION

The PAX2D Digital Panel Meter offers many features and performance

capabilities that are not available on standard panel meters. The basic meter is a

dual counter and dual rate meter all in the same package. A third counter and

third rate display allows the user to do simple math functions. The optional plug-

in output cards allow the opportunity to configure the meter for present

applications, while providing easy upgrades for future needs.

Highlighting the PAX2D is a dual line, display with a large 0.71" tri-color 6

digit top display line and a 0.35", 9 digit green bottom display line. The meter

also offers programmable units display providing the ability to tag the display

with units of measure. Display color change capability provides machine

operators a visual indication of changing conditions, even when the operator is

not close enough to read the actual display value. In addition, a universal power

supply provides the ultimate in flexibility for both AC and DC power.

The meter accepts digital inputs from a variety of sources including switch

contacts, outputs from CMOS or TTL circuits, magnetic pickups and all

standard RLC sensors. The meter can process directional, uni-directional or

Quadrature signals simultaneously. The meter accepts input signals up to 50

KHz maximum depending on the count mode and function configurations

programmed. Each input signal can be independently scaled to various process

values.

The meter provides a MAX and MIN rate reading memory with programmable

capture time. The capture time is used to prevent detection of false max or min

readings which may occur during start-up or unusual process events.

The meter has up to four setpoint outputs, implemented on plug-in option

cards. The plug-in cards provide dual FORM-C relays, quad FORM-A, or either

quad sinking or quad sourcing open collector logic outputs. The setpoint alarms

can be configured to suit a variety of control and alarm requirements.

The PAX2 can be programmed to utilize Modbus protocol. With Modbus, the

user has access to most configuration parameters. Readout values and setpoint

alarm values can be controlled through the bus. Additionally, the meter has a

feature that allows a remote computer to directly control the outputs of the

meter. Communication and bus capabilities are also available as option cards.

These include RS232, RS485, DeviceNet, and Profibus-DP.

The PAX2 includes a built-in USB programming port. With a Windows

®

based program, made available by Red Lion Controls, configuration data can be

downloaded to the PAX2 without the need of any additional option cards.

A linear DC output signal is available as an optional plug-in card. The card

provides either 20 mA or 10 V signals. The output can be scaled independent of

the input range and can track any of the counter, rate, max or min displays, or

any setpoint value.

After the meter has been initially configured, the parameter programming

may be locked out from further modification in its entirety, or allowing selected

values accessible for quick entry.

The meter has been specifically designed for harsh industrial environments.

With NEMA 4X/IP65 sealed bezel,extensive testing of noise effects with regard

to CE requirements, the meter provides a tough reliable application solution.

SAFETY SUMMARY

All safety related regulations, local codes and instructions that appear in this

literature or on equipment must be observed to ensure personal safety and to

prevent damage to either the instrument or equipment connected to it. If

equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired. Do not use this unit to directly

command motors, valves, or other actuators not equipped with safeguards. To do

so can be potentially harmful to persons or equipment in the event of a fault to

the unit.

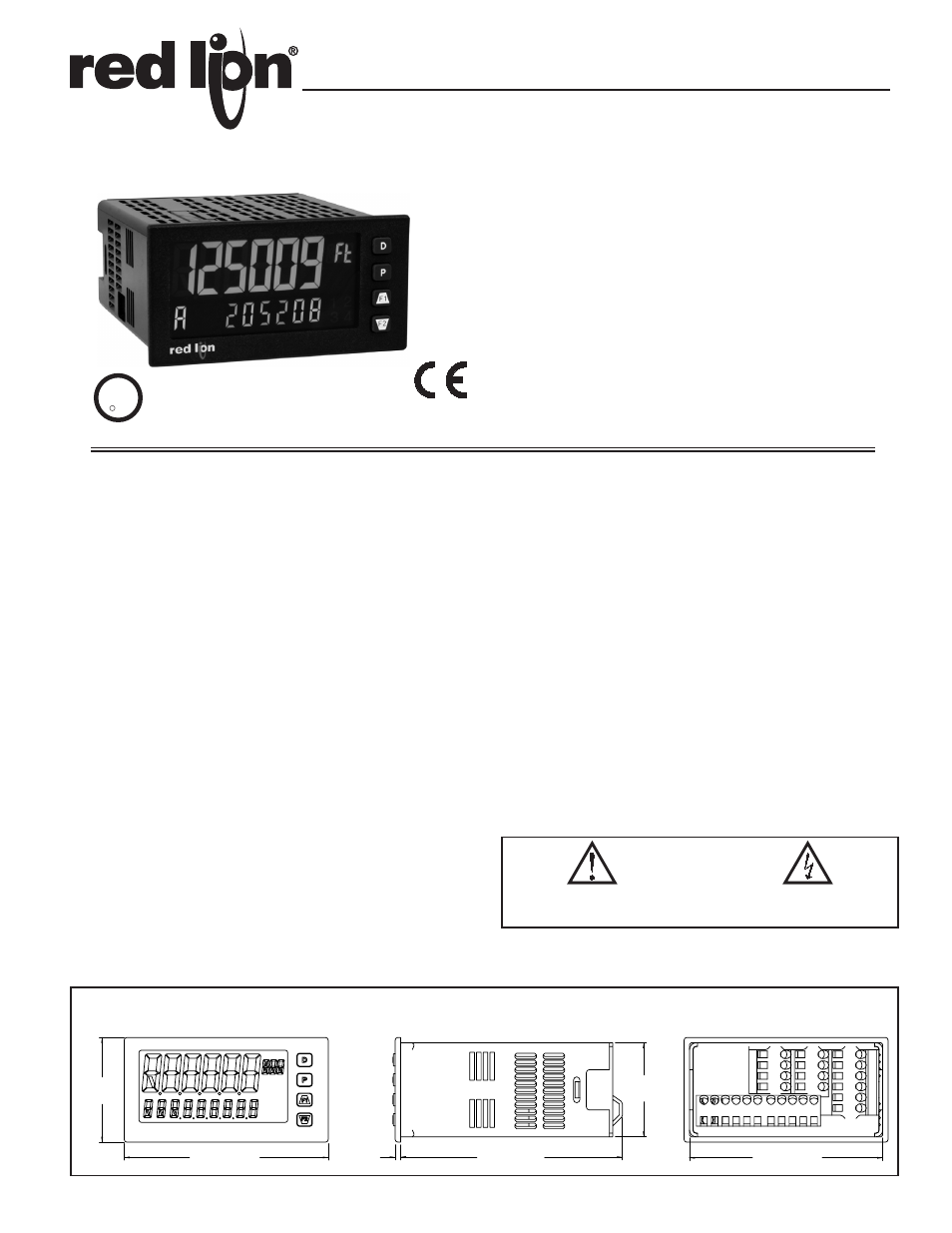

MODEL PAX2D – 1/8 DIN DIGITAL INPUT PANEL METER

DIMENSIONS In inches (mm)

Note: Recommended minimum clearance (behind the panel) for

mounting clip installation is 2.1" (53.4) H x 5.5" (140) W.

Bulletin No. PAX2D-B

Drawing No. LP0872

Released 04/13

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

www.redlion.net

CAUTION: Risk of Danger.

Read complete instructions prior to

installation and operation of the unit.

CAUTION: Risk of electric shock.

C

US LISTED

UL

R

3RSD

PROCESS CONTROL EQUIPMENT