Installation for flow measurement, 7 error messages – KROHNE OPTISONIC 6300 P-6400 EN User Manual

Page 33

INSTALLATION FOR FLOW MEASUREMENT

3

33

OPTISONIC 6300 P

www.krohne.com

03/2013 - 4000972603 - MA OPTISONIC 6300 P R03 en

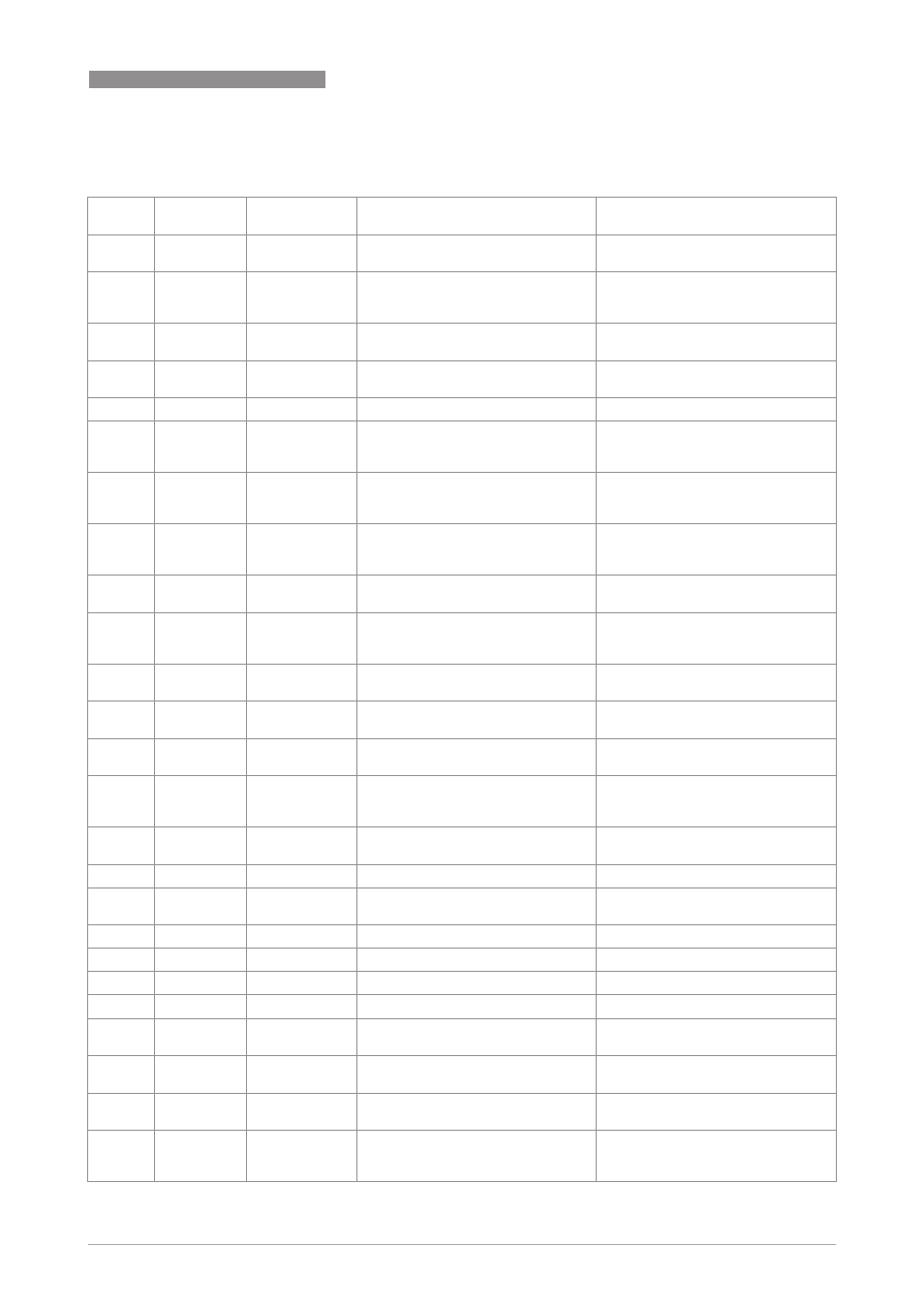

3.7 Error messages

Error

Error

Error

Error

code

code

code

code

Group

Group

Group

Group

message

message

message

message

Error message

Error message

Error message

Error message

Description

Description

Description

Description

Error handling

Error handling

Error handling

Error handling

F (bold)

F (bold)

F (bold)

F (bold)

error in

device

no measurement possible,

measured values are not valid

repair or replace device and/or CPU;

contact manufacturer service center

F

application

error

no measurement possible, but

device ok

check parameter settings / power

off - wait 5 seconds - power on

device

S

out of

specification

unreliable measurement

maintenance required, check

flowprofile

C

check in

progress

test function is active, device is

stand-by

wait until finished

I

information

no direct impact on measurements

no action needed

F (bold)

F (bold)

F (bold)

F (bold)

IO 1 (or IO 2)

error or failure of IO Module 1 (or 2)

try to load settings (menu C8.6.3);

if error does not disappear, replace

electronics unit

F (bold)

F (bold)

F (bold)

F (bold)

parameter

error or failure of data manager,

parameter or hardware error

try to load settings (menu C8.6.3);

if error does not disappear, replace

electronics unit

F (bold)

F (bold)

F (bold)

F (bold)

configuration

incorrect configuration or no

confirmation

confirm change of module;

if configuration is unchanged,

replace electronics unit

F (bold)

F (bold)

F (bold)

F (bold)

display

error of failure of display unit,

parameter or hardware error

defect; replace electronics units

F (bold)

F (bold)

F (bold)

F (bold)

current output

A (or B, C)

error or failure of the current output

A (or B, C), parameter or hardware

error

defect; replace electronics units

F (bold)

F (bold)

F (bold)

F (bold)

software user

interface

defect; replace electronics units

F (bold)

F (bold)

F (bold)

F (bold)

hardware

settings

detected hardware and set hardware

settings do not match

follow display instructions

F (bold)

F (bold)

F (bold)

F (bold)

hardware

detection

hardware can not be detected

defect; replace electronics units

F (bold)

F (bold)

F (bold)

F (bold)

RAM/ROM

error IO 1

(or IO 2)

defect; replace electronics units

F (bold)

F (bold)

F (bold)

F (bold)

communication

dsp-up

no communication between DSP and

microprocessor PCB

contact manufacturer service center

F (bold)

F (bold)

F (bold)

F (bold)

front end

malfunctioning of front end PCB

contact manufacturer service center

F (bold)

F (bold)

F (bold)

F (bold)

uproc

malfunctioning of microcontroller

PCB

contact manufacturer service center

F (bold)

F (bold)

F (bold)

F (bold)

dsp

malfunctioning of DSP

contact manufacturer service center

F

empty pipe

signal lost at two paths

check process conditions

F

flow > max 1

max volume flow exceeded for pipe 1 check parameter in menu C1.7.1

F

flow > max 2

max volume flow exceeded for pipe 2 check parameter in menu C1.7.1

F

open circuit A

(or B, C)

current on current output A (or B, C)

too low

check cable or reduce resistance

(< 1000 Ohm)

F

over range A

(or B, C)

current on current output A (or B, C)

is limited by parameter setting

extend upper or lower limit for

current output in menu C5.2.8

F

over range A

(or B, D)

pulse on frequency output A (or B, D)

is limited by parameter setting

extend upper or lower limit for

frequency output in menu C5.3.7

F

active settings

error during CRC check (Cyclic

Redundancy Check) of the active

settings

load settings; factory setting, back

up 1 or back up 2