Installation for flow measurement, 2 step 1: find location and determine data – KROHNE OPTISONIC 6300 P-6400 EN User Manual

Page 13

INSTALLATION FOR FLOW MEASUREMENT

3

13

OPTISONIC 6300 P

www.krohne.com

03/2013 - 4000972603 - MA OPTISONIC 6300 P R03 en

3.2 Step 1: Find location and determine data

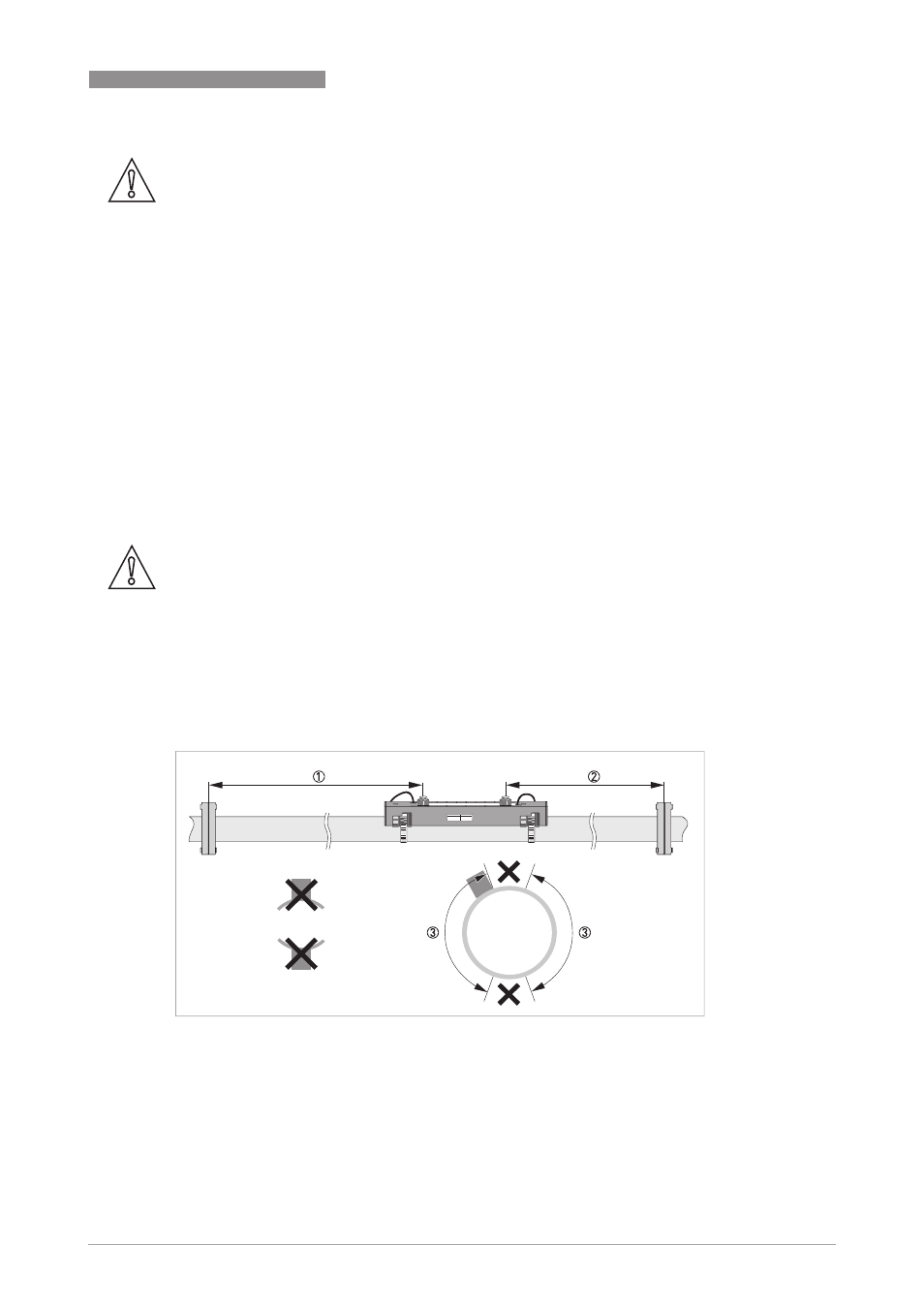

Inlet, outlet and recommended mounting area

To perform an accurate flow measurement preferably mount the sensor rail at least 10 DN

downstream of a flow disturbance like elbows, valves, headers or pumps. Follow the given

installation recommendations.

CAUTION!

•

In order to comply with the EMC directive 2004/108/EC, I/O cables that provide a galvanic

connection to the UFC 300 P should have a maximum total length of 3 meter.

•

When not used, put the connector covers of the connectors on the bottom side of the

converter in place. This to prevent improper functioning caused by dust/dirt.

•

When the sensor cables are connected while the converter is positioned on a flat surface,

turn the handle fully backwards (towards the housing) in order to prevent excess stress on

the sensor cables.

•

In order to keep the battery at an optimum condition the battery should be charged at least

once every 6 months.

•

If the main battery is empty for a period longer than one year, the backup battery of the real

time clock may run empty.

•

The protection degree of the battery charger / mains adapter is IP 40 / NEMA 1. It should be

protected against moisture entering.

•

To prevent damage due to vibrations, do not firmly attach the converter to or place it on top of

a vibrating object.

CAUTION!

Do not start to mount the rails yet! Step 1 is only meant to find a suitable location for a

measurement. The installation itself will be done in Step 3.

Figure 3-1: Inlet, outlet and recommended mounting area

1 Min. 10 DN

2 Min. 5 DN

3 Recommended installation location (120°)