0 maintenance, 1 maintenance schedule, 2 storage – Seed Hawk AIRCART 2013 User Manual

Page 39

SEED HAWK

®

AIRCART OPERATOR’S MANUAL 34

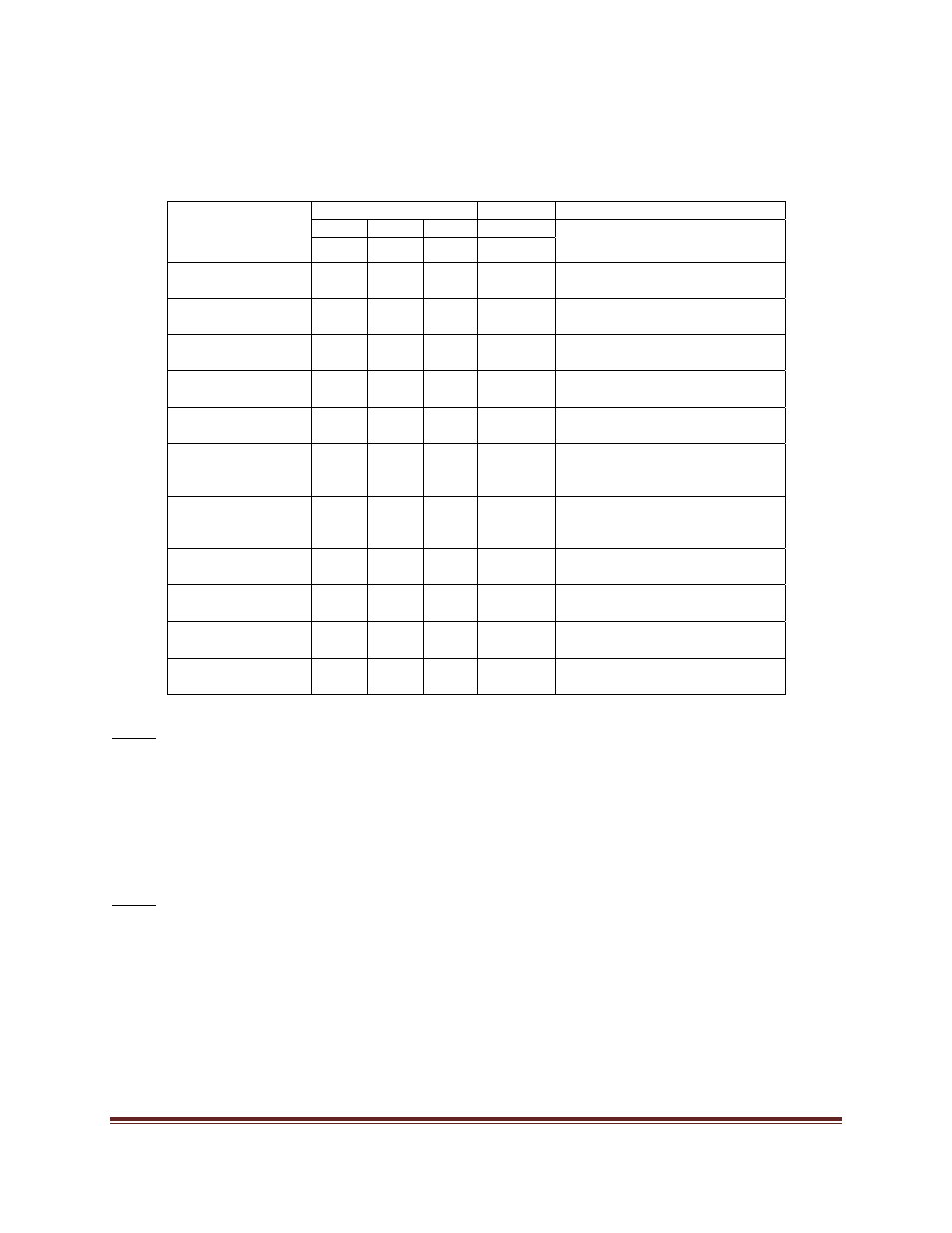

5.0 MAINTENANCE

5.1 MAINTENANCE SCHEDULE

Item

Procedure

Frequency

Notes

check

lube

clean

hours

Wheel Hubs

main frame

100

100 hr or annually

re‐pack bearings or 2 pumps grease

Metering System

sprockets and chains

25

25 hr or every 2 days

use dry graphite lubricant

Metering Components

100

100 hr, or, before seeding, or,

between product changes

Fan System

intake

10

10 hr or daily

remove accumulated debris

Fan System

fan blades

10

10 hr or daily

must be intact and clean

Fill Auger or Conveyor

System

100

when changing between products,

or,

when stored for long periods of time

Tanks and meters

100

When changing between products,

or, when stored for long periods of

time

Fill Auger System

pillow block bearings

10/100

10 hr or daily, and,

100 hr or annually

Fill Auger System

universal joints

10/100

10 hr or daily, and,

100 hr or annually

Hydraulic Return Line

open ‐ drain in pail

100

at end of seeding season, or,

when stored for long periods of time

Tires

air pressure

10

10 hr or daily

inflate to proper pressure

NOTE: The bearings on each Stainless Steel meter are sealed.

DO NOT GREASE THESE BEARINGS.

5.2 Storage

Prior to storage remove all product from tanks, meters, and fill auger (or conveyor).

NOTE: Failure to remove product prior to storage will greatly increase the rate of corrosion in

the tanks and meter.

As well, ensure that the meters are thoroughly vacuumed or washed. If the aircart is washed

be sure to dry the system out afterwards by opening the lids and running the fans for 30

minutes. This will prevent damage occurring from ice buildup, and prevent product sticking to

wet components which creates blockages. When stored outside tightly cover the fans to seal

water out of the airstreams. The service life of the aircart seals can be extended by unlatching

the lids and loosening the thumb nuts on the cleanout doors.