9 fan(s), 10 checking air and product flow – Seed Hawk AIRCART 2013 User Manual

Page 37

SEED HAWK

®

AIRCART OPERATOR’S MANUAL 32

4.9 FAN(S)

Connect the pair of 3/4” hydraulic lines (Fan one has a blue band, fan two has a red band) to

supply the hydraulically driven fan motor. This tractor lever is locked in full pressure position

while seeding.

Some models are configured with a single fan while others may be configured with dual fans.

Fans are driven by hydraulic motors with speed controlled by the tractor hydraulic flow system.

Fan speed is indicated on the monitor panel in the cab.

Set fan speed to effectively transport the seed. Higher fan speeds will increase seed bounce,

and possibly damage the seed. Higher fan speeds also require more power input from the

tractor.

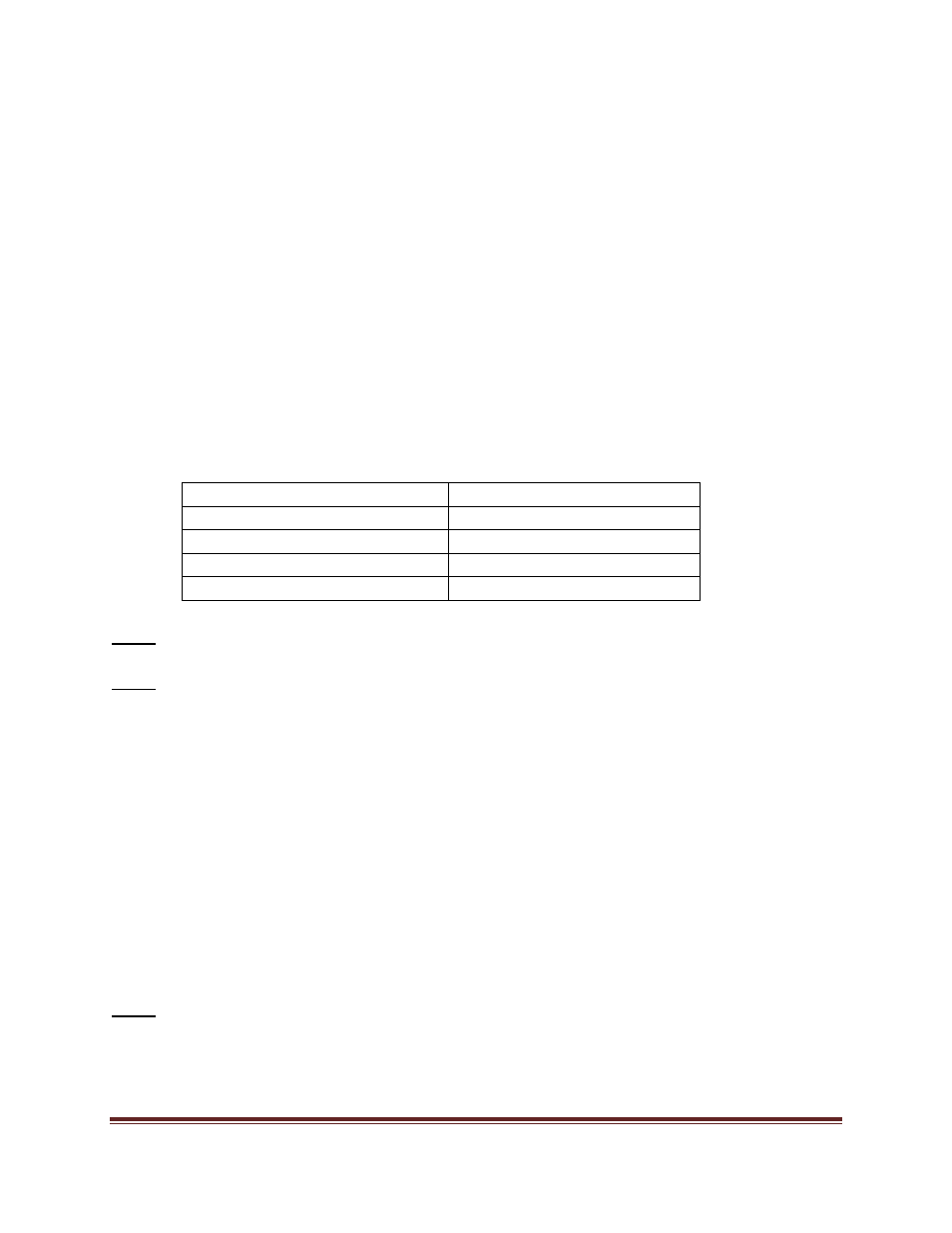

Typical fan speed ranges for various product types are listed below for reference:

PRODUCT

FAN SPEED (rev/min)

Oilseeds

2000‐3000

Cereals

2500‐4000

Pulse Crops

3500‐4200

Fertilizer (granular)

3500‐4200

NOTE: Fan Speed is dependent on implement size and tractor hydraulic output.

NOTE: If Aircart is equipped with two fans, if one fan is not being used, it must be ran at low

rpm due to pressurization of meters.

4.10 CHECKING AIR AND PRODUCT FLOW

The test procedure outlined below serves as a guideline for ensuring proper fan speed for

effective delivery of product:

1. Remove hose(s) from an outside opener and temporarily attach to the frame of the

seeder with the hose looping no more than 12 in (300 mm) below the frame.

2. Begin seeding at normal field speed and observe distance product discharges from

hose(s) attached to the frame.

NOTE: All product should discharge within a range of 12 ‐ 24 in (300 ‐ 600 mm).

3. Adjust fan speed, if necessary, to ensure optimum air flow for product discharge.