Optional function, Performance, Standard requirements for sample gas – Yokogawa IR400 User Manual

Page 98

9 - 3

IM 11G02N01-01E

3. Optional function

O

2

correction: Correction of measured NO, SO

2

and CO

gas concentrations into values at reference

O

2

concentration

Correction formula:

C = –––––––– x C

s

C

: Sample gas concentration after O

2

correction

C

s

: Measured concentration of sample

gas

O

s

: Measured O

2

concentration (Limit set-

ting: 1 to 20% O

2

, default

17%)

O

n

: Reference O

2

concentration

(value changeable by setting.0 to 19%

O

2

, default 4%)

Average value after O

2

correction and O

2

average value

calculation:

The result of O

2

correction or instanta-

neous O

2

value can be outputted as an av-

erage value in the preset period of time.

Used for averaging is the moving average

method in which sampling is carried out at

intervals of 30 seconds.

(Output is updated every 30 seconds. It is

the average value in the determined period

of time just before the latest updating.)

Averaging time is settable within 1 to 59

minutes (in increments of 1 minute) or 1 to 4

hours (in increments of 1 hour).

Average value resetting:

The above-mentioned output of average

value is started from the initial state by

opening the average value resetting input

terminals after short-circuiting for 1.5 sec-

onds or longer.

Output is reset by short-circuiting and re-

started by opening

CO concentration peak count alarm:

(added only for CO/O

2

measurement)

Alarm output turns on according to the pre-

set concentration and count.

Whenever the instantaneous value of CO

exceeds the preset concentration value,

count increments. If the count exceeds the

preset value in one hour, the alarm contacts

close.

Communication function:

RS-232C (9pins D-sub)

Half-duplex bit serial

Start-stop synchronization

ModbusTM protcol

Contents : Read/Wright parameters

Read measurement concentra-

tion and instrument status

Remark : When connecting via RS-485

interface, a RS-232C RS-

485 converter should be used.

21-O

n

21-O

s

4. Performance

Repeatability :

±

0.5% of full scale

Linearity

:

±

1% of full scale

Zero drift

:

±

1% of full scale/week

(

±

2% of full scale/week; range

between 0 to 50ppm and 0 to

200ppm)

(

±

2% of full scale/day; smaller

than 0 to 50ppm range)

Span drift

:

±

2% of full scale/week

(

±

2% of full scale/day; smaller

than 0 to 50ppm range)

Response time (for 90% FS response) :

Within 60 seconds including re-

placement time of sampling gas

(when gas flow rate is 0.5L/min)

Gas replacement time depends

on the number of measuring

components,and measuring

range

ffects of interfering gases

When sample gas contains gas components

listed below, the measurement accuracy may

suffer. Consult Yokogawa for countermeasures

or effect on accuracy.

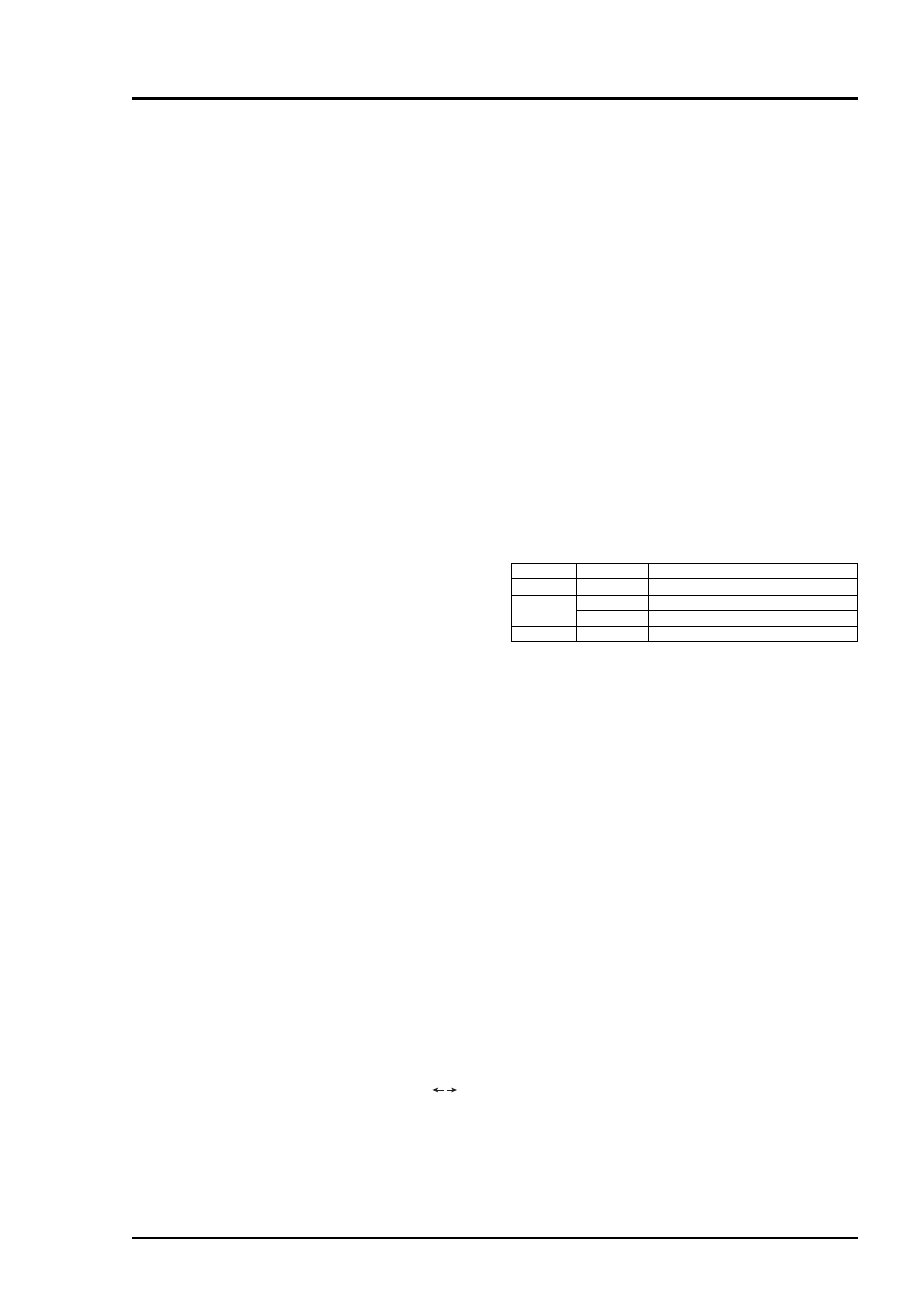

T03s.EPS

CO

2

15% of CO

2

is equivalent to 7 to 10 ppm of CO

15% of CO

2

is equivalent to approx. 3 ppm of CH

4

Analyzer

SO

2

analyzer

CO analyzer

Interference gas

Effect

NO

2

50 ppm of NO

2

is equivalent to -6 ppm of SO

2

CH

4

analyzer

CO

2

N

2

O

1000 ppm of N

2

O is equivalent to 80 ppm of CO

5. Standard Requirements for Sample Gas

Flow rate

: 0.5

±

0.2L / min

Temperature : 0 to 50˚C

Pressure

: 10 kPa or less (Gas outlet side

should be open to the atmo-

spheric air.)

Dust

: 100

µ

g/Nm

3

in particle size of

1

µ

m or less

Mist

: Unallowable

Moisture

: Below a level where saturation

occurs at 2˚C (condensation un-

allowable).

Corrosive component: Hcl

1 ppm or less

Standard gas for calibration:

Zero gas ; Dry N

2

Span gas ; Each sample gas

having concentra-

tion 90 to 100% of its

measuring range

(recommended).

Gas beyond con-

centration 100%FS

is unusable.

In case a zirconia O

2

analyzer is

installed externally and calibra-

tion is carried out on the same

calibration gas line:

Zero gas ; Dry air or atmo-

spheric air (provided

without CO

2

sensor)