2 troubleshooting – Yokogawa IR400 User Manual

Page 94

8 - 3

IM 11G02N01-01E

8.2 Troubleshooting

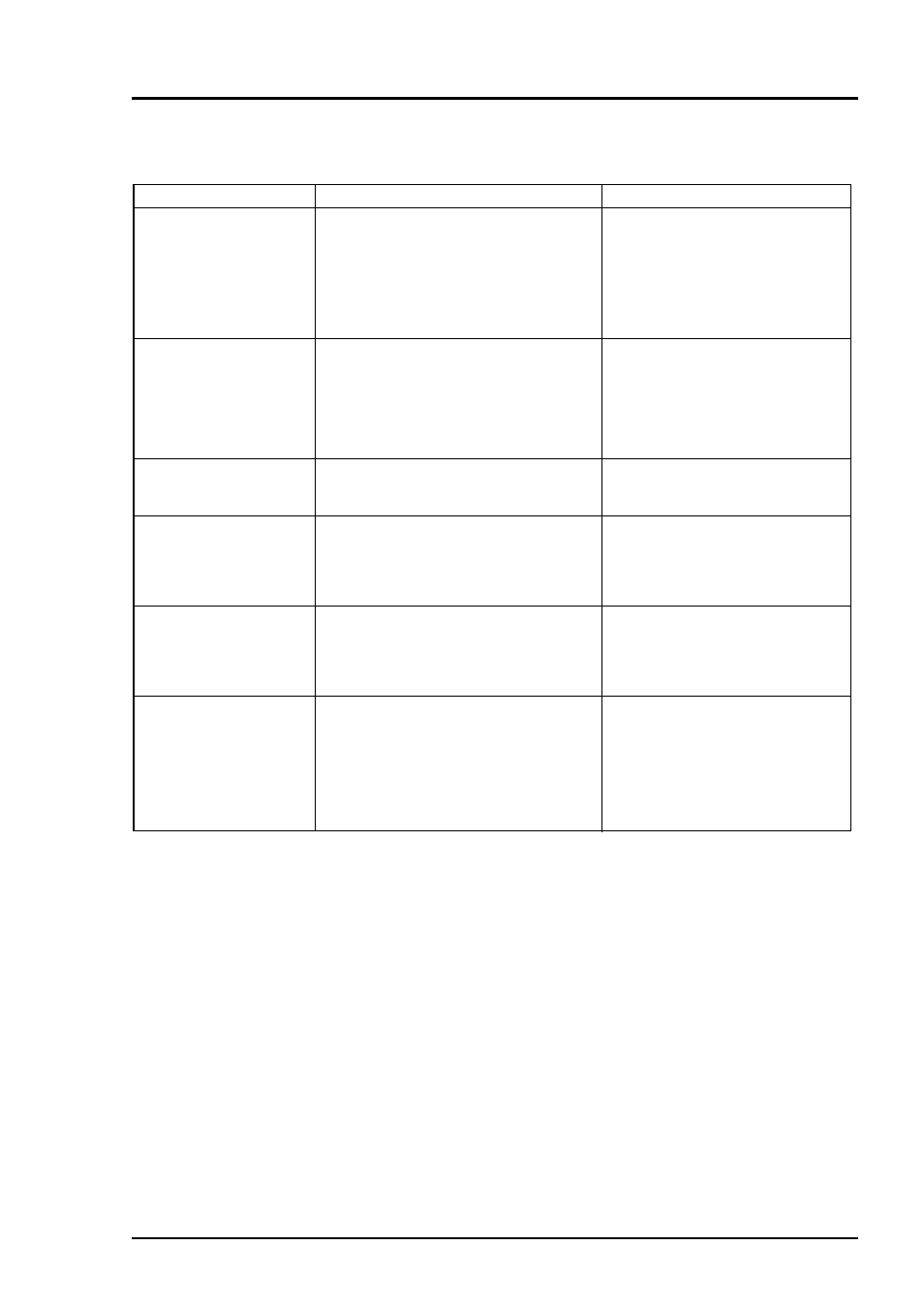

The following table shows how to remedy other troubles, such as faulty readings.

• Check if the zero gas is supplied to the

analyzer at the specified flow rate.

• Check the optical balance.

(See Subsection 7.3.3, "Optical zero

adjustment method.")

• Check the count value on the display

panel. (Refer to the sensor input value by

maintenance mode.)

• Check if the span gas is supplied to the

analyzer at the specified flow rate.

• Check if zero calibration can be performed

properly.

• Check the count value on the display

panel. (Refer to the sensor input value by

maintenance mode.)

• Take either of the above remedies

depending of the source of the error: zero

calibration or span calibration trouble.

• Check if the sample gas is supplied to the

analyzer at the specified flow rate.

• Check the optical system, e.g., the sample

cell window, O-ring, detector window and

inside of the cell for heavy dirt.

• Check for the influence of interference

from moisture.

• Check if the sample gas contains

interfering components in large quantities

or not.

• Check if the sample gas is supplied to the

analyzer at the specified flow rate.

• Check if the zero and span calibration is

enabled.

Zero calibration fails.

Error No. 4, 5, or 8 occurs.

Span calibration fails.

Error No. 6, 7, or 8 occurs.

Error occurs during auto

calibration.

Error No. 9 occurs.

Drift.

Readings are abnormally

high or low.

Readings do not increase.

• Locate and check gas leaking points,

and take the proper remedy.

• Adjust the optical balance.

• Locate and check gas leaking points,

and take the proper remedy.

• If zero calibration fails, first attempt

remedies for zero calibration trouble.

• Are there any changes from when

zero gas is supplied?

• Locate and check gas leaking points,

and take the proper remedy. (See

Section 3.3.)

• Clean the cell and window. Replace the

part.(See Subsections 7.3.1 and 7.3.2.)

• Adjust interference from moisture.

• Investigate the components of the

sample gas and then contact our

serviceperson.

(See Sec. 9.1 item 4.)

• Locate and check gas leaking points,

and take the proper remedy. (See

Section 3.3.)

• If enabled, sampling (check the

points relating only to the sample gas

and take the proper remedy.)

• If not enabled, check the calibration

related error items.

Symptom

Checking Item

Remedy, etc.

T8.2.eps