ଙଝ ଝ – Yokogawa IR400 User Manual

Page 90

7 - 9

IM 11G02N01-01E

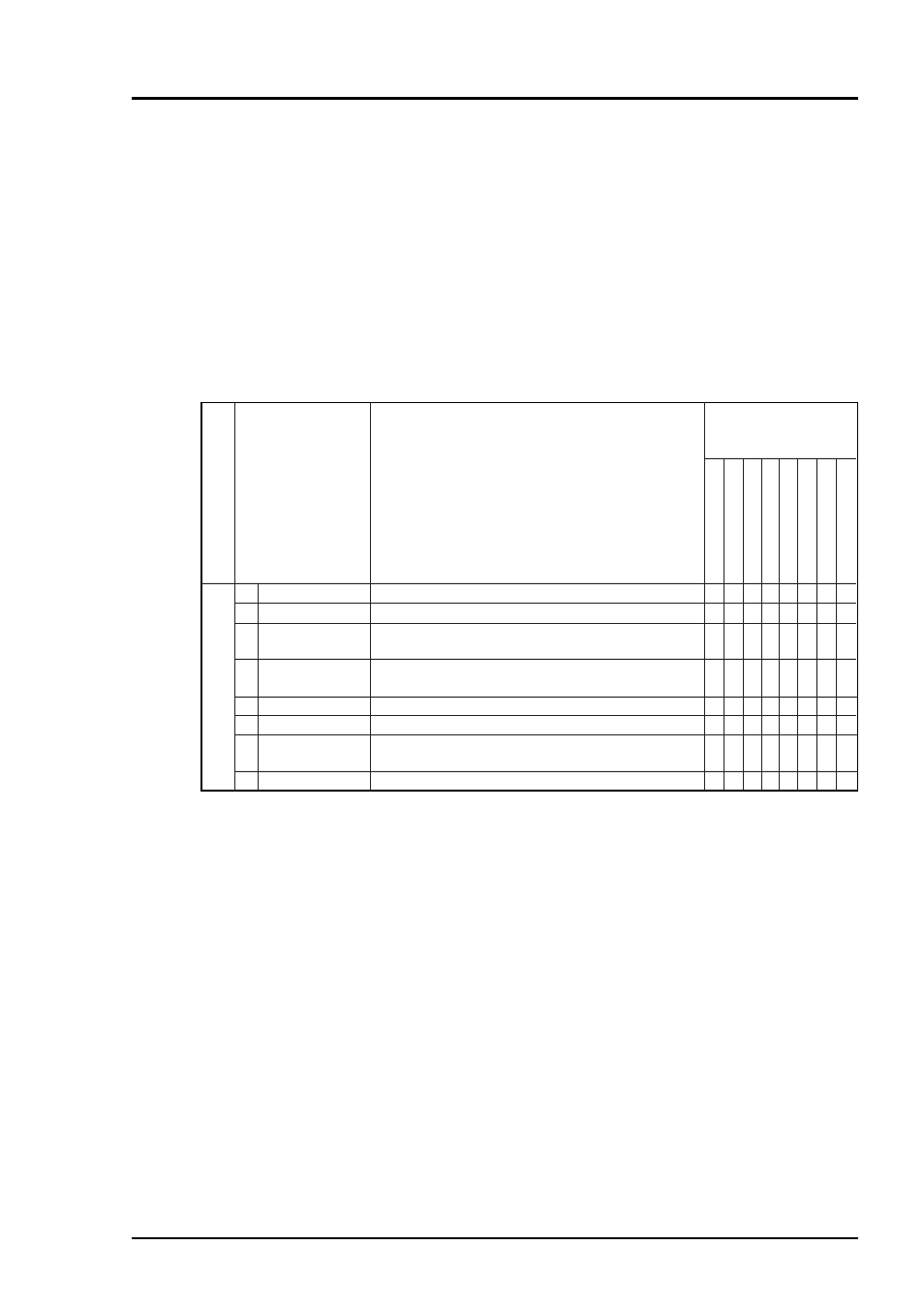

7.4 Inspection and maintenance of limited service-life components

The analyzer uses limited-life components. The recommended replacement periods are listed in

the below table.

(1) Limited service-life components are those which wear out or for which failure is presumed

within five years under normal operating or storage conditions. Components with more than

five years of service life are the exception.

(2) The following table only involves the recommended periods for conducting preventive main-

tenance for limited service-life components; these periods do not guarantee that accidental

failures will not occur.

(3) The recommended replacement periods are tentative and depend on operating conditions.

(4) The recommended replacement periods may vary depending on the field date.

1. Light source

Recommended replacement period: Every five years (*1)

2. Sector motor

Recommended replacement period: Every two years (*1)

3. Detector without

Recommended replacement period: Every five years (*1)

O

2

sensor

4. O-ring

Recommended replacement period: Every two years,

inspect it when cleaning of measuring cell. See Sec. 7.3

5. LCD panel

Recommended replacement period: Every five years (*1)

6. Power supply

Recommended replacement period: Every five years (*1)

7. Measuring cell

Set up an appropriate maintenance period

( by refering to the check results)

8. Reference cell

Recommended replacement period: Every five years (*1)

Checkpoint

Infrared gas analyzer

Check and

maintenance items

Procedure and criteria

Recommended check and

maintenance periods

Every five years

Every two years

Once a year

Every six months

Every three months

Once a month

Once a week

Routine

(*) In the check and maintenance columns, place a check mark (

᭺

) for check and confirmation work,

a dark star (

ଙ

) for replacement, and a white star (

ଝ

) for parts preparation for preventive maintenance.

(*1) These are seviceperson’s work, contact our sevicepersons.

ଙ

ଙ

ଙ

ଙ

ଝ

ଝ

᭺

᭺

T7.5E.eps

ଝ

᭹

Precautions to be taken while checking

(1) When handling reference gas (during calibration), carefully read the reference-gas instruc-

tion manual to use the gas correcrtly. In particular, special attention must be taken in han-

dling carbon monoxide gases; otherwise, you may suffer from gas poisoning.

(2) During maintenance checks, be sure to keep the near fan on. If any gas leaks, you may suffer

from gas poisoning.

(3) When replacing the analyzer gas filter or conducting maintenance service of the washer,

completely shut the calibration-gas valve. Otherwise, you may suffer from gas poisoning.