Nonlinear output curve, Independent heat and cool pid, Variable time base – Watlow Series SD31 PID with Optional Countdown Timer User Manual

Page 57

The Power Limit 1and 2 (

[PL`1] and [PL`2] ) and

Output Power Scale Low 1 and 2 (

[PSL1] and [PSL2])

and Output Power Scale High 1 and 2 (

[PSH1] and

[PSH2] ) appear on the Setup Page. The calculated PID

heat and cool power values can be viewed with Power

Heat

[Po;ht] and Power Cool [Po;CL] parameters on

the Operations Page.

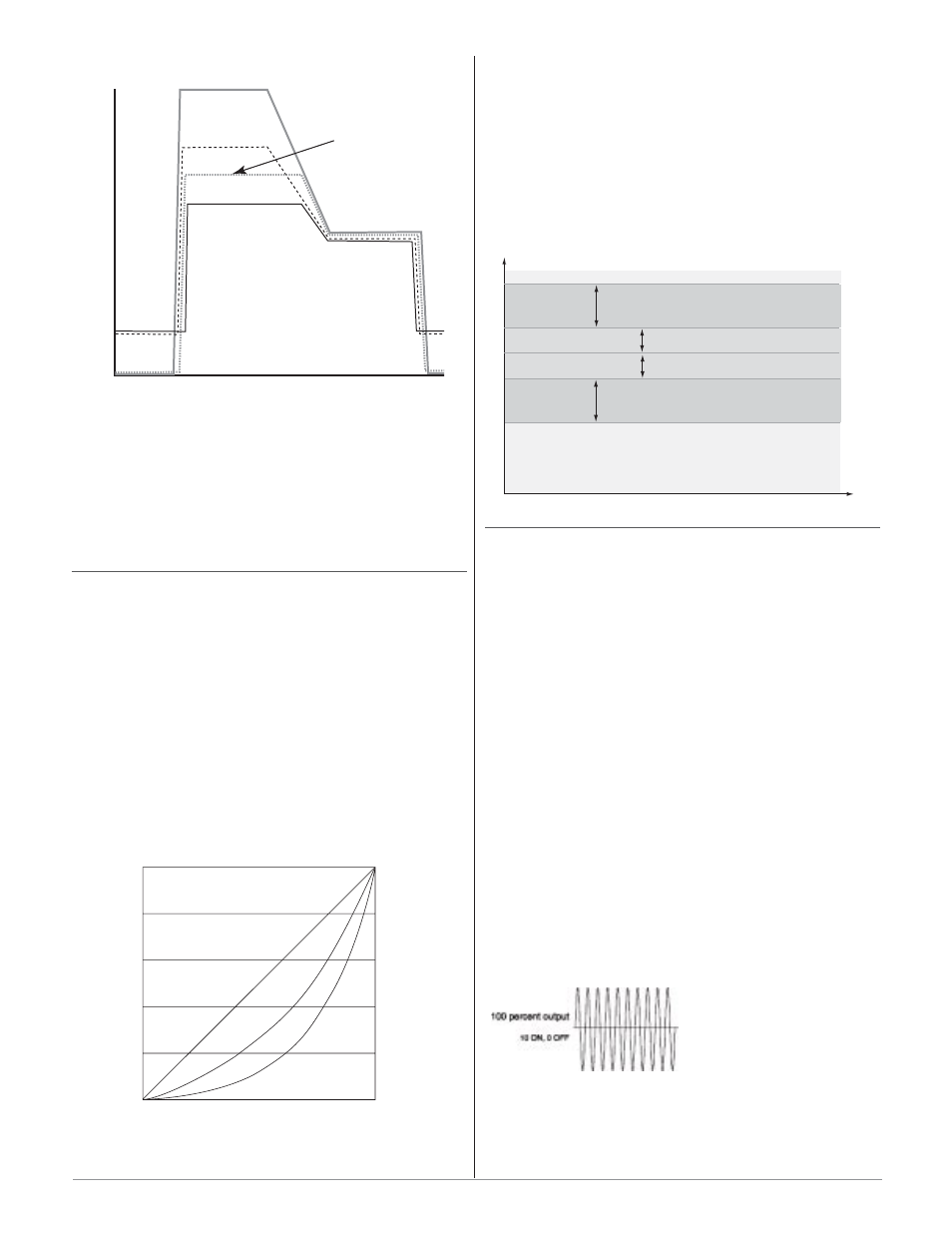

Nonlinear output curve

A nonlinear output curve may improve performance

when the response of the output device is nonlinear. If

Output Nonlinear Function is set to curve 1

[Cru1] or

curve 2

[Cru2], a PID calculation yields a lower actual

output level than the linear output provides. These out-

put curves are used in plastics extruder applications.

Curve 1 is for air cooled extruders and curve 2 is for wa-

ter cooled extruders.

Change the linearity for each output with Output

Nonlinear Function 1 or 2 (

[nLf1] or [nlf2] ) on the

Setup Page.

Independent Heat and Cool PID

In an application with one output assigned to heat-

ing and another assigned to cooling, each will have a

separate set of PID parameters and separate dead

bands. The heating parameters take effect when the

process temperature is lower than the set point and the

cooling parameters take effect when the process temper-

ature is higher than the set point.

Adjust heat and cool PID parameters are Operations

parameters.

Variable Time Base

Variable time base is the preferred method for con-

trolling a resistive load, providing a very short time

base for longer heater life. Unlike phase-angle firing,

variable-time-base switching does not limit the current

and voltage applied to the heater.

With variable time base outputs, the PID algorithm

calculates an output between 0 and 100%, but the out-

put is distributed in groupings of three ac line cycles.

For each group of three ac line cycles, the controller de-

cides whether the power should be on or off. There is no

fixed cycle time since the decision is made for each

group of cycles. When used in conjunction with a zero

cross (burst fire) device, such as a solid-state power con-

troller, switching is done only at the zero cross of the ac

line, which helps reduce electrical noise (RFI).

Variable time base should be used with solid-state

power controllers, such as a solid-state relay (SSR) or sili-

con controlled rectifier (SCR) power controller. Do not use

a variable time base output for controlling electromechani-

cal relays, mercury displacement relays, inductive loads or

heaters with unusual resistance characteristics.

Time

Temperature

Set Point

Heating Side Proportional Band

Heating Side Dead Band

Cooling Side Dead Band

Cooling Side Proportional Band

Actual Output P

o

w

er

0

20

40

60

80

100

PID Calculation

Linear

Curve 1

Curve 2

100

90

80

70

60

50

40

30

20

10

0

P

ercent P

o

w

er Output

Time

➔

Power Limit 100%

Power Scale Low 0%

Power Scale High 100%

Power Limit 100%

Power Scale Low 15%

Power Scale High 80%

Power Limit 70%

Power Scale Low 0%

Power Scale High 100%

Power Limit 70%

Power Scale Low 15%

Power Scale High 80%

Wa t l o w S e r i e s S D 3 1

■

5 5

■

C h a p t e r 1 0 F e a t u r e s