Saving and restoring user settings, Operations page, Autotuning – Watlow Series SD31 PID with Optional Countdown Timer User Manual

Page 51

Saving and Restoring User Settings

Recording setup and operations parameter settings

for future reference is very important. If you uninten-

tionally change these, you will need to program the cor-

rect settings back into the controller to return the

equipment to operational condition.

After you program the controller and verify proper

operation, use

[USr;S] to save the settings into a special

section of memory. If the settings in the controller are

altered and you want to return the controller to the

saved values, use

[USr;R] to recall the saved settings.

To save the Setup and Operations parameters:

1.

Ensure all the settings that you want to store are

already programmed into the Setup Page and Oper-

ations parameters.

2.

Press the Up

¿ and Down ¯ keys together for six

seconds until

[Fact] appears in the display.

3.

Press the Down Key

¯ to step through the parame-

ters until the

[USr;S] parameter appears.

4.

Press and hold the

ß Key and change [`~no] to

[SEt1] or [SEt2] by pressing the Down Key ¯.

5.

Release the

ß Key and press the Infinity Key ˆ

to exit the Factory Page.

Note: Only perform the above procedure when you are sure that all

the correct settings are programmed into the controller. Saving the

settings overwrites any previously saved collection of settings. Be

sure to document all the controller settings.

To restore a collection of saved settings:

1.

Press the Up

¿ and Down ¯ keys together for six

seconds until

[Fact] appears in the display.

2.

Press the Down Key

¯ to step through the parame-

ters until the

[USr;R] parameter appears.

3.

Press and hold the

ß Key and change [`~no] to

[SEt1] or [SEt2] by pressing the Down Key ¯.

4.

Release the

ß Key and press the Infinity Key ˆ

to exit the Factory Page.

Operations Page

Watlow’s patented user-defined menu system im-

proves operational efficiency. The user-defined Opera-

tions Page provides you with a shortcut to monitor or

change the parameter values that you use most often.

You can go directly to the Operations Page from the

Home Page by pressing and holding the Infinity Key

‰.

You can create your own Operations Page with as

many as 20 of the active parameters from the list in the

Keys and Displays chapter. When a parameter normally

located on the Setup Page is placed on the Operations

Page, it is accessible through both. If you change a pa-

rameter on the Operations Page, it is automatically

changed in its original page. If you change a parameter

in its original page it is automatically changed on the

Operations Page.

The default parameters will automatically appear on

the Operations Page.

To change the list of parameters appearing on the

Operations Page, hold down the Infinity key

ˆ, then

press the Advance Key

‰, and hold both down for about

six seconds until

[Prog] appears in the display. This is

the Programming Page.

Press the Down Key

¯ once to go to the first Pro-

gramming Page selection. The parameter choices P1-

P20 appear in the display. Press and hold the

ß Key

and use the Up

¿ or the Down ¯ Key to change the se-

lected parameter for each Programming Page location.

If you do not want a parameter to appear for that loca-

tion, select

[nonE]. To change the other 19 selections,

release the

ß Key and use the Up ¿ or the Down ¯

Key to select

[``P1] to [`p20].

Changes made to the Operations Page will persist

until changed by the operator or defaulted by full de-

faults or user defaults. User-defined parameters are not

over-written by default parameters if those features be-

come enabled. Only parameters supported by a con-

troller’s particular hardware configuration and pro-

gramming settings will appear.

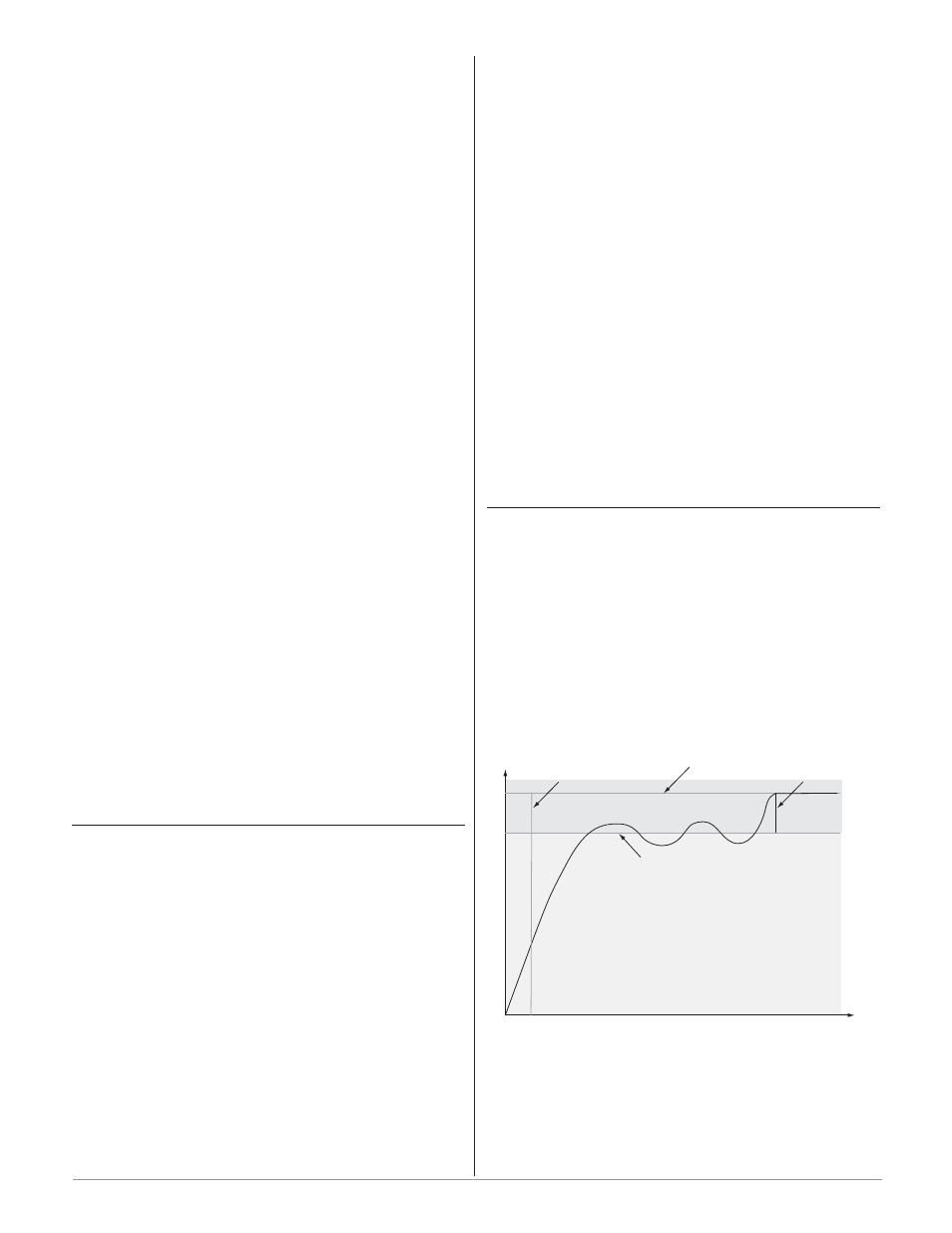

Autotuning

The autotuning feature allows the controller to

measure the system response to determine effective set-

tings for PID control. When autotuning is initiated the

controller reverts to on-off control. The temperature

must cross the Autotune Set Point four times to com-

plete the autotuning process. Once complete, the con-

troller controls at the normal set point, using the new

parameters.

To initiate an autotune, set Autotune

[`Aut] (Oper-

ations parameters) to

[``On].

Time

Temperature

Autotune begins

Process Set Point

Autotune Set Point

(90 percent of Process Set Point)

Autotune complete

Wa t l o w S e r i e s S D 3 1

■

4 9

■

C h a p t e r 1 0 F e a t u r e s