Manual tuning, Inputs, Infosense™ temperature sensing – Watlow Series SD31 PID with Optional Countdown Timer User Manual

Page 52: Calibration offset

Manual Tuning

In some applications, the autotune process may not

come up with PID parameters that provide the process

characteristics you desire. If the autotune does not pro-

vide satisfactory results, you will have to perform a

manual tune on the process:

1. Apply power to the Series SD31 and establish a

set point typically used in your process.

2. Go to the Operations Page, and establish values

for the PID parameters: Proportional Band = 5; Reset* =

0.00; Rate* = 0.00. Note: Autotune should be set to off.

3. When the system stabilizes, watch the process val-

ue. If this value fluctuates, increase the proportional

band setting until it stabilizes. Adjust the proportional

band in 3° to 5° increments, allowing time for the sys-

tem to stabilize between adjustments.

4. When the Input has stabilized, watch the percent

power , (Po.ht or Po.cl). It should be stable ±2%. At this

point, the process temperature should also be stable, but

it will have stabilized before reaching set point. The dif-

ference between set point and actual can be eliminated

with reset.

5. Start with a reset* value of 0.01 (99.99)** and al-

low 10 minutes for the process temperature to get to set

point. If it has not, double (halve) ** the setting and

wait another 10 minutes. Continue doubling (halving) **

every 10 minutes until the process value equals the set

point. If the process becomes unstable, the reset* value

is too large (small) **. Decrease (increase) ** the reset

value until the process stabilizes.

6. Increase Rate* to 0.10 minute. Then increase the

set point by 11° to 17°C. Monitor the system's approach

to the set point. If the process value overshoots the set

point, increase Rate* to 0.50 minute. Increase the set

point by 11° to 17°C and watch the approach to the new

set point. If you increase Rate* too much, the approach

to the set point will be very sluggish. Repeat as neces-

sary until the system rises to the new set point without

overshoot or sluggishness.

*With the

[unit] parameter set at [SI] ( Setup

Page) Integral will appear in place of Reset and Deriva-

tive will appear in place of Rate.

**Integral is the reciprocal of reset. For Integral in-

stead of reset, use the values in parentheses.

For additional information about autotune and PID

control, see related features in this chapter.

Inputs

INFOSENSE™ Temperature Sensing

Watlow’s INFOSENSE™ feature can improve tem-

perature sensing accuracy by 50%. Watlow’s INFO-

SENSE™ thermocouples and RTD temperature sensors

must be used together to achieve these results.

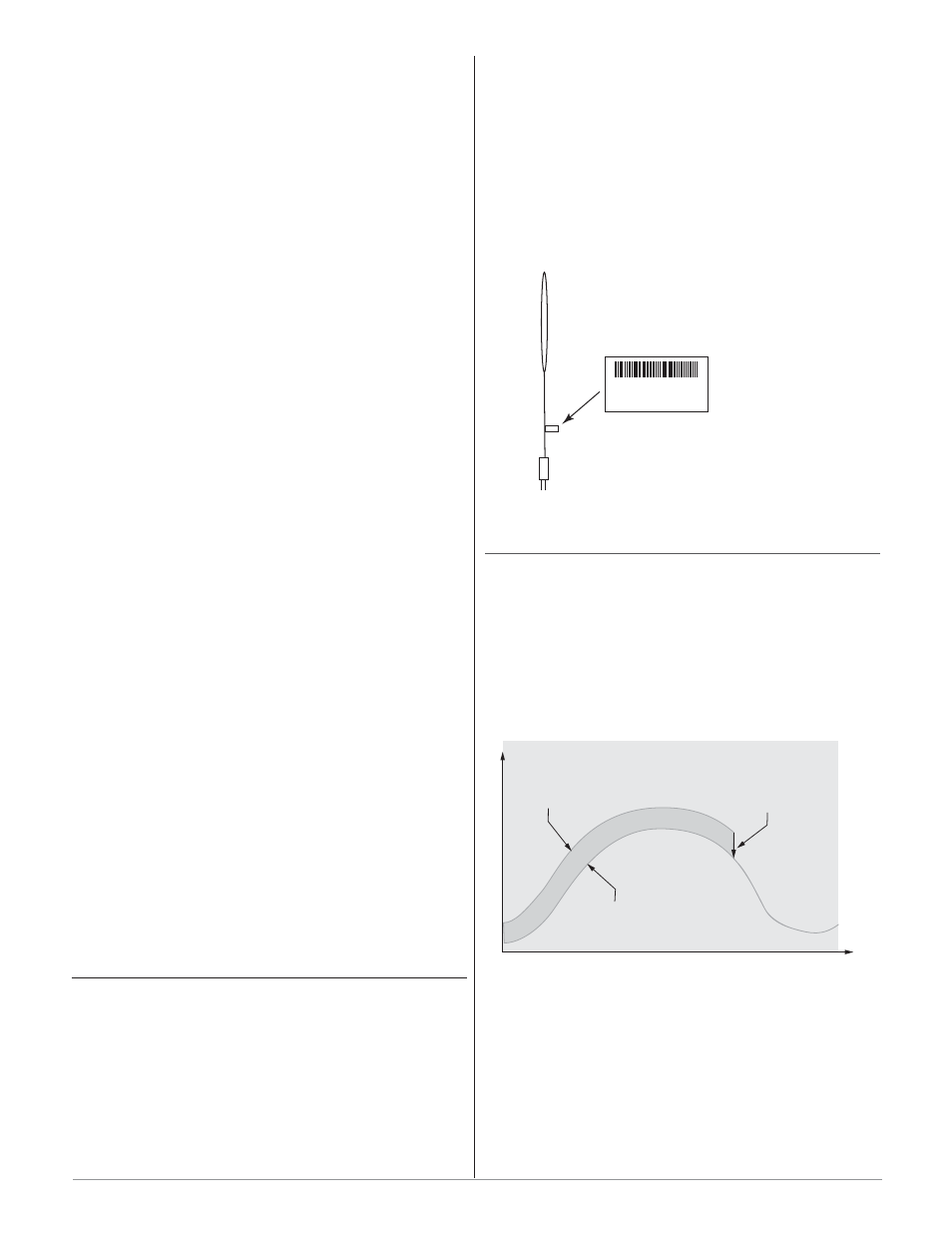

Each INFOSENSE™ “smart” sensor contains four

numeric values that are programmed into the SD mem-

ory. These values characterize Watlow sensors, for the

controller to provide greater accuracy.

Turn the INFOSENSE™ feature on or off with

INFOSENSE™ Enable

[IS;En] (Setup Page). Set the

four numerical values supplied with Watlow’s INFO-

SENSE™ in the

[IS;P1], [IS;P2], [IS;P3] and [IS;P4]

parameters.

Contact your Watlow salesperson or Watlow author-

ized distributor for the pricing and availability of Wat-

low INFOSENSE™ products.

The four numerical values are found on the tag at-

tached to the sensor.

Calibration Offset

Calibration offset allows a device to compensate for

an inaccurate sensor, lead resistance or other factors

that affect the input value. A positive offset increases

the input value, and a negative offset decreases the in-

put value.

The input offset value can be viewed or changed with

Calibration Offset

[`CAL] (Operations parameters).

Time

Temperature

Temperature Reading

from Sensor

Actual Process Temperature

Negative Calibration Offset will

compensate for the difference

between the Sensor Reading and

the Actual Temperature

IS1 IS2 IS3 IS4

123 456 789 258

Wa t l o w S e r i e s S D 3 1

■

5 0

■

C h a p t e r 1 0 F e a t u r e s