IAI America IF User Manual

Page 57

5. Maintenance inspection

51

6) Adjust the belt tension until the specified tension value is reached.

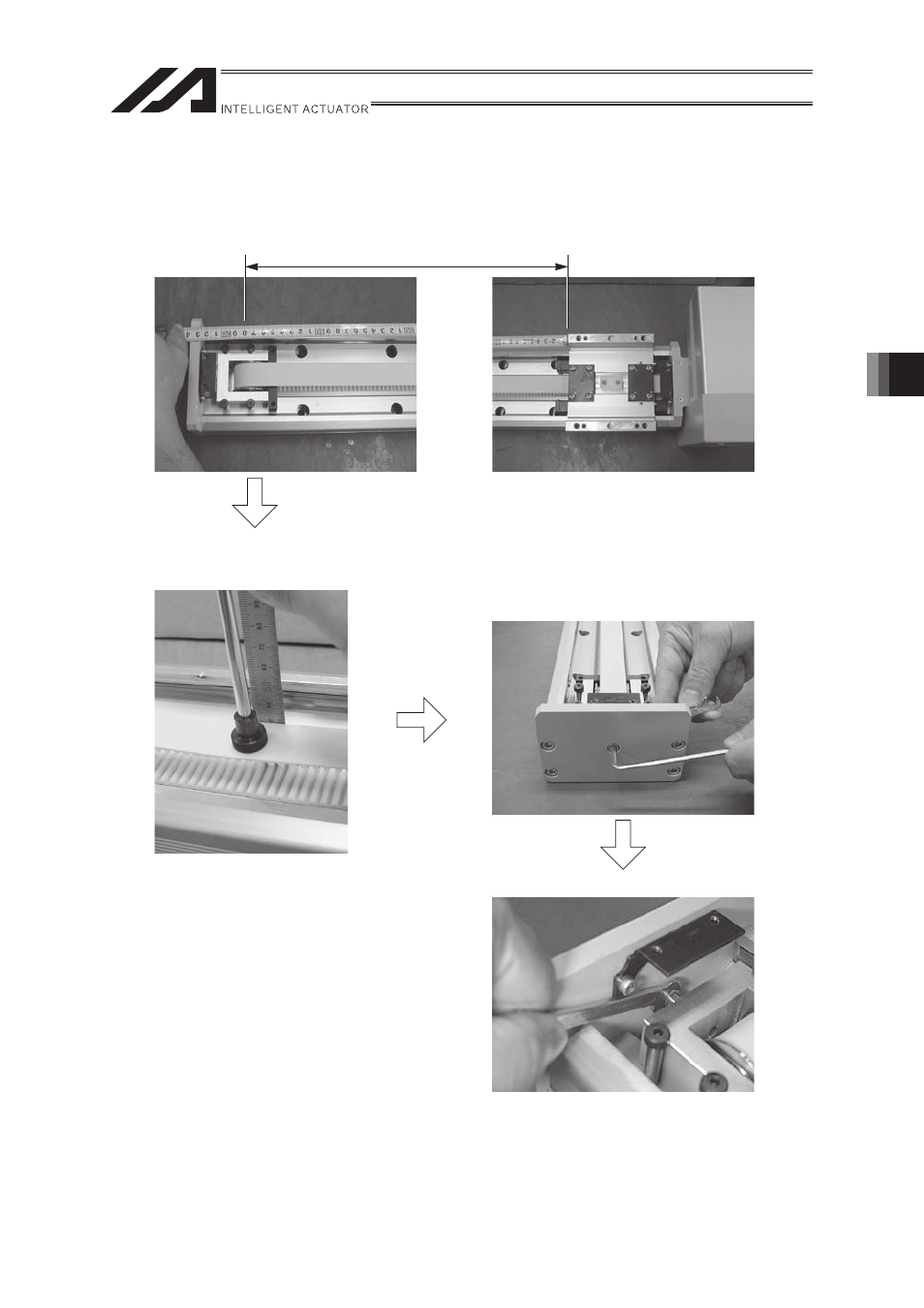

• Move the slider to the mechanism end on the motor side.

Measure the distance from the slider side to the pulley center and mark the central position.

Measure this distance and find the central position.

• Press the push-pull gauge against the central position and tighten the adjusting bolt so

that the specified values for the deflection load and deflection are reached. (Refer to

“How to Adjust the Driver Belt Tension” for the specified values).

• Tighten the hexagon nut securely.

7) Attach the belt cover.

See also other documents in the category IAI America Hardware:

- ERC2 (138 pages)

- ERC2 (188 pages)

- ERC3 (438 pages)

- ERC (153 pages)

- RCA-E (53 pages)

- RCA-P (42 pages)

- RCB-101-MW (38 pages)

- RCP2-C (178 pages)

- RCS-E (102 pages)

- RCA-A4R (72 pages)

- RCA-RA3C (114 pages)

- RCA-SRA4R (56 pages)

- RCA2-RA2AC (100 pages)

- RCA2-SA2AC (92 pages)

- RCA2-TA4C (134 pages)

- RCD-RA1D (40 pages)

- RCP2-BA6 (72 pages)

- RCP2-GRSS (130 pages)

- RCP2-HS8C (126 pages)

- RCP2-RA2C (120 pages)

- RCP2-RTBS (80 pages)

- RCP2W-SA16C (46 pages)

- RCP3-RA2AC (60 pages)

- RCP4-RA5C (82 pages)

- RCP4-SA5C (94 pages)

- RCP4W (96 pages)

- RCS2-F5D (142 pages)

- RCS2-GR8 (46 pages)

- RCS2-RN5N (80 pages)

- RCS2-RT6 (60 pages)

- RCS2-SA4C (258 pages)

- RCS2-TCA5N (62 pages)

- RCL-SA1L (66 pages)

- RCL-RA1L (56 pages)

- RCLE-GR5L (46 pages)

- IK Series (16 pages)

- FS (84 pages)

- ISB (114 pages)

- ISDA (126 pages)

- ISDB (116 pages)

- ISPWA (90 pages)

- NS (78 pages)

- ICS(P)A (16 pages)

- RS (46 pages)