IAI America IF User Manual

Page 37

2. Installation

31

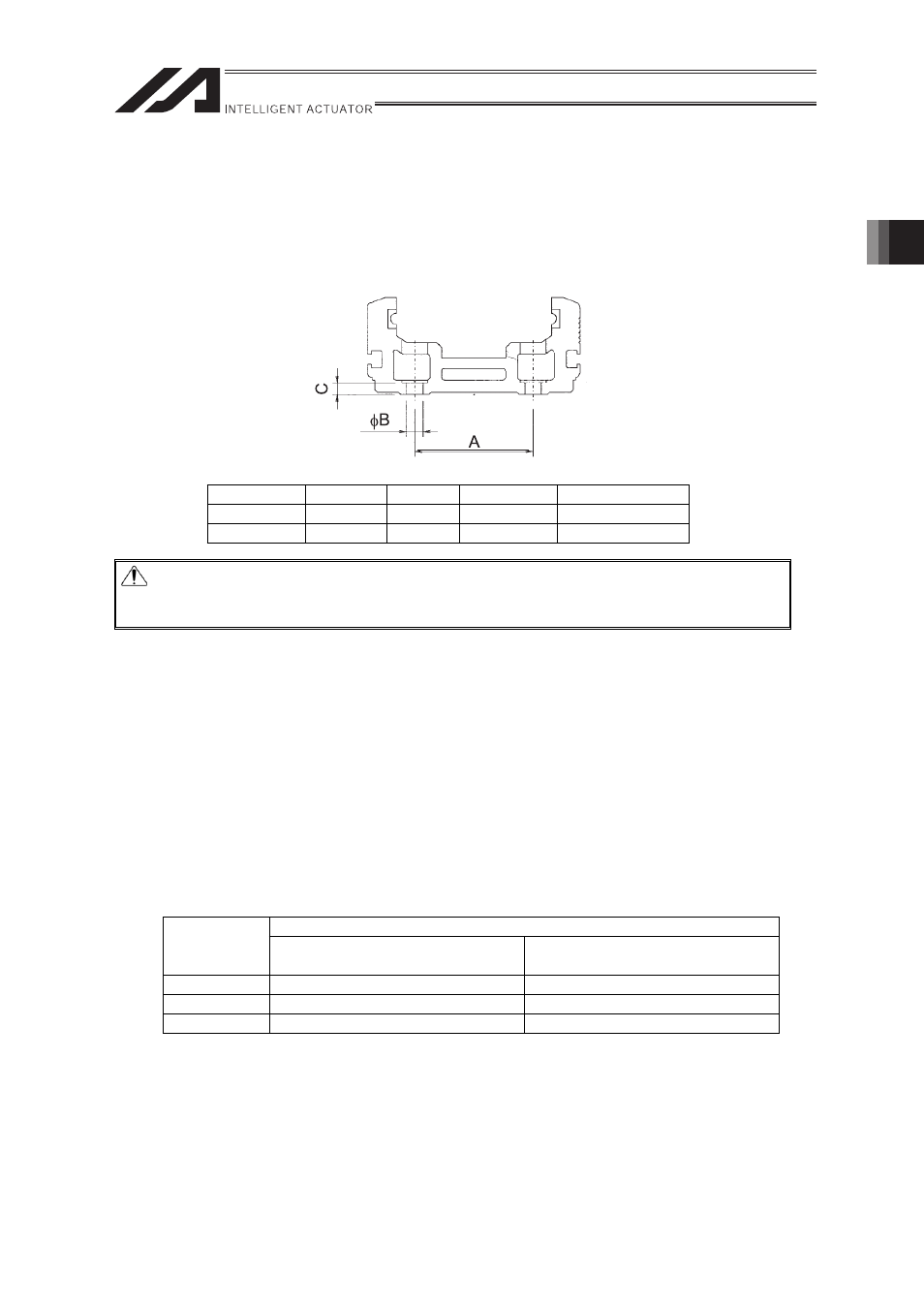

(2) Mounting method

x

There is a set hole on the actuator base. Fix the actuator using this set hole.

x

The belt cover can be removed using the hexagon wrench with the distance to the

opposite side of 2 mm.

x

For the set bolt, use hexagon socket head cap screw with the intensity classification of

10.9 or more and fasten it with the attached special washer.

Caution: Make sure to use the attached special washer. If the actuator is mounted

without using this washer, the bolt might be loosened due to the buckling on

the bolt-seated surface.

x

Use a hex socket head cap screw for the attachment to the base.

x

It is recommended to use high-tensile bolts with ISO-10.9 or more.

x

Make sure to have the effective length of screw engagement described below or more for

the tightening of a bolt and a female screw.

x

When female screw is on steel ĺ thread length same as nominal diameter

x

When female screw is on aluminum ĺ thread length 2 times longer than nominal

diameter

x

When using a bolt sized M8 or more and the seat for the bolt is made of aluminum, apply a

washer dedicated for high-tensile bolts (otherwise the bolt seat may sink). It is not

necessary if the bolt is M6 or smaller. Please do not apply a standard spring lock washer.

The recommended screw torque is given below.

Tightening Torque

Screw

nominal

diameter

In the case that steel is used for

the bolt seating surface:

In the case that aluminum is

used for the bolt seating surface:

M5

7.5N·m (0.77kgf·m)

4.3N·m (0.44kgf·m)

M6

12.9N·m (1.32kgf·m)

6.7N·m (0.68kgf·m)

M8

31.3N·m (3.19kgf·m)

14N·m (1.43kgf·m)

Model

A

B

C

Mounting screw

S Type

50mm

7

5mm

M6

M Type

70mm

9

6mm

M8