FEC AFC1200 User Manual

Page 10

)(& ,QF

2-3b.

THE pulldown menu will display three input mode selections:

[FASTENING]

FASTENINg parameter set screen

[SPEED]

Speed parameter set screen

[REVERSE]

REverse parameter set screen

2-3c. Using

the

[↑] [↓]

keys, select the desired input mode and depress the

[↵]

key. The selected input mode screen will now be displayed.

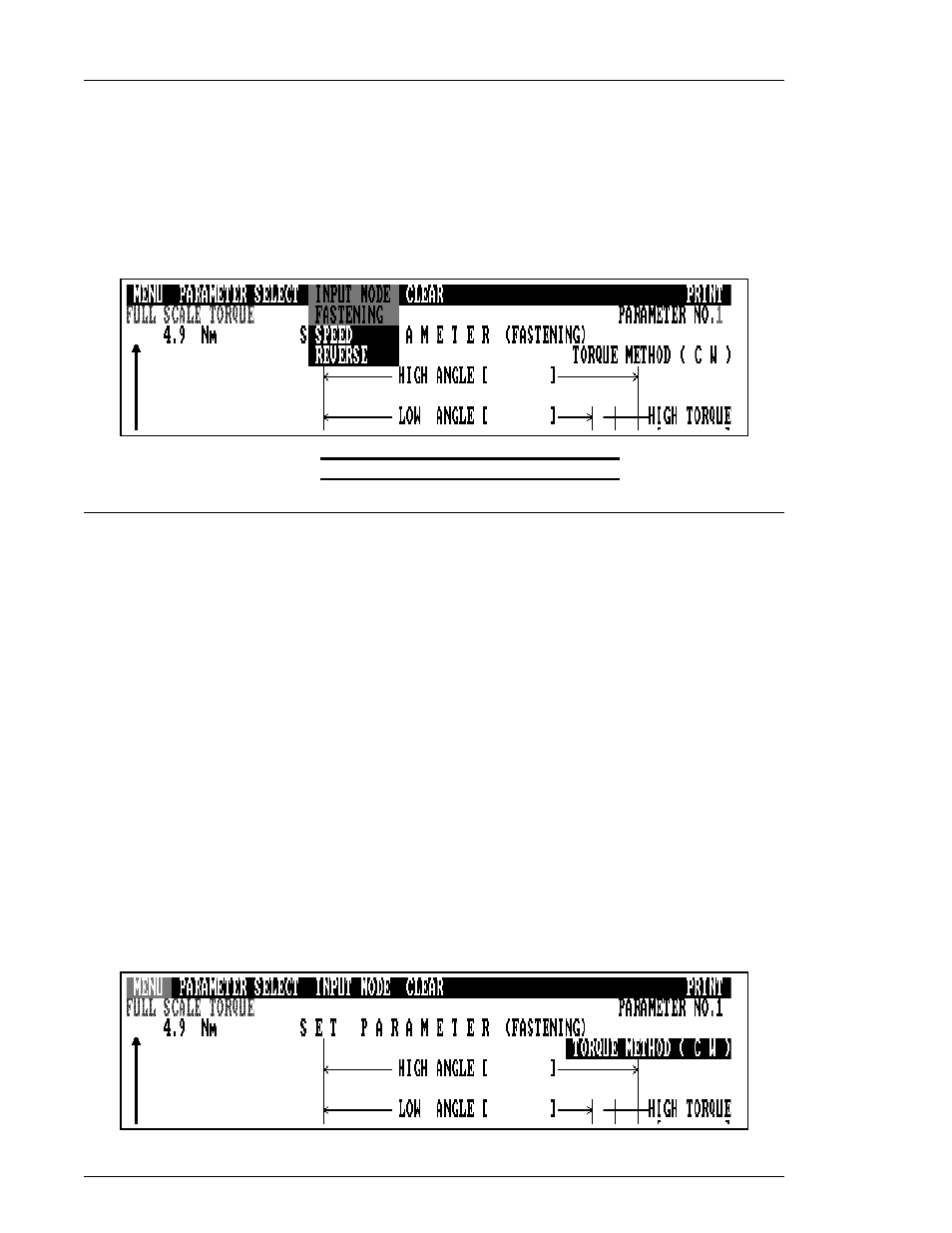

FIG. 7-1-2-3 set parameter [INPUT MODE]

7.1.3 FASTENING PARAMETER SETUP

THe function of this screen is to preset the following parameters:

fastening method

yield (control values)

tool type

yield (monitor values)

torque (control values)

torque rate (monitor values)

torque (monitor values)

angle (control values)

angle (monitor values)

3-1.

SELect FASTENING METHOd

3-1a.

Move the cursor on the menu bar to [INPUT MODE], select [FASTENING]

and depress the

[↵]

key. The screen displayed will be the "SET PARAMETER

(FASTENING)" screen. (Check the PARAMETER No. to ensure the correct number

has been selected).

3-1b.

Depress the [SEL] key. THe fastening method will be highlighted. Use the

[←] [→]

keys to scroll through the fastening method options, and depress the

[↵]

key to select an option. THE screen will change to the "SET PARAMETER

(FASTENING)" screen for the selected fastening method.

NOTE: Clockwise (CW) or counterclockwise (CCW) fastening is chosen as part of the fastening

method.

For Angle Method, three (3) options are available: CCW, CW SNUG, and CW SEAT.

Typically, SNUG method should be chosen for a clockwise fastening. (SEAT method is

primarily used in Systems operating outside of the United States.)

Chapter 7: System Operation

Page 7-10