Installation – Controlled Products Systems Group 222X383 User Manual

Page 19

Installation and Maintenance Manual

11

D0119, Rev. F

Installation

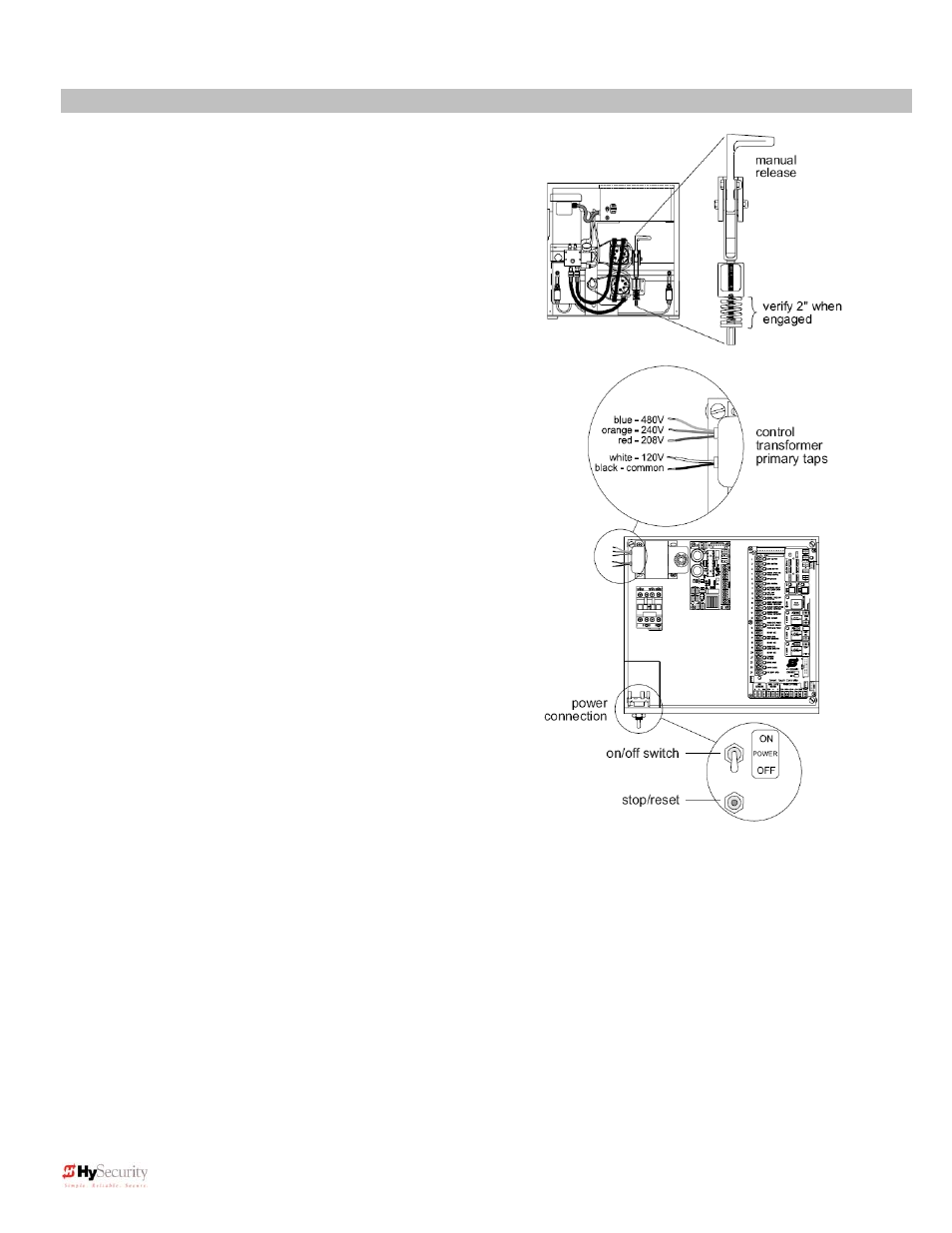

6. Clamp the Drive Wheels to the Drive Rail

When the wheels are fully clamped on the drive rail, the red

spring should be compressed to 2” in height. If adjustment

is necessary, turn the nut at the bottom of the threaded rod

assembly. Slightly less compression is okay for lighter

gates. See Use of Manual Release on page 54

7. Electrical Power Connection

This operator is intended for permanent installation, so all

electrical conduits must be properly connected to the control

box. The entry for the primary power is a ½ - ¾” knockout

on the left side of our control box next to the on-off switch.

When this operator was manufactured, it was built to run on

a specific voltage and phase for line power. Make sure you

have compared the line voltage and phase available with the

nameplate on this machine. They must match! Be certain

that the wire size of the branch circuit that will supply the

operator vs. the distance of the run from the main panel is

large enough to avoid excess voltage drop. At a minimum, a

20 amp circuit (protected with a 20 Amp Inverse Time

Breaker) should be provided. Also be sure the operator is

electrically well grounded per NEC Article 250 and local

codes. See pages 61 and 62 for correct wire sizes and

detailed electrical wiring information.

8. Primary Tap of Control Transformer

(not on battery operators)

Check to make sure that the primary tap on the control

transformer matches the line voltage you have connected to

the operator. Measure the line voltage carefully to

distinguish between 208V and 230V branch circuits. A label

on top of the transformer identifies the various voltage taps.

9. Electrical Power for Two Part 333 type operators

The primary AC power must be routed to the controller

enclosure with the pump, but there must also be conduits between

the gate operator and the controller enclosure.

Note: AC power is not needed in the gate operator, unless there is an optional heater. A minimum of two

separate conduits must be provided, 2” for the hydraulic hoses and ¾” for the electrical interconnections.

Unless there are accessories in the gate operator, the only electrical interconnection between the two

enclosures will be three wires between the two terminal strips for the limit switches. Join the hydraulic

hoses by plugging the quick coupling together according to the hand of the gate. See the on page 59.