Brooks, Mf series – Brooks Instrument Mfi Series User Manual

Page 54

4-16

Brooks

®

Mf Series

Section 4 Maintenance &

Troubleshooting

Installation and Operation Manual

X-TMF-Mfi-Mfx-MFC-eng

Part Number: 541B074AAG

August, 2009

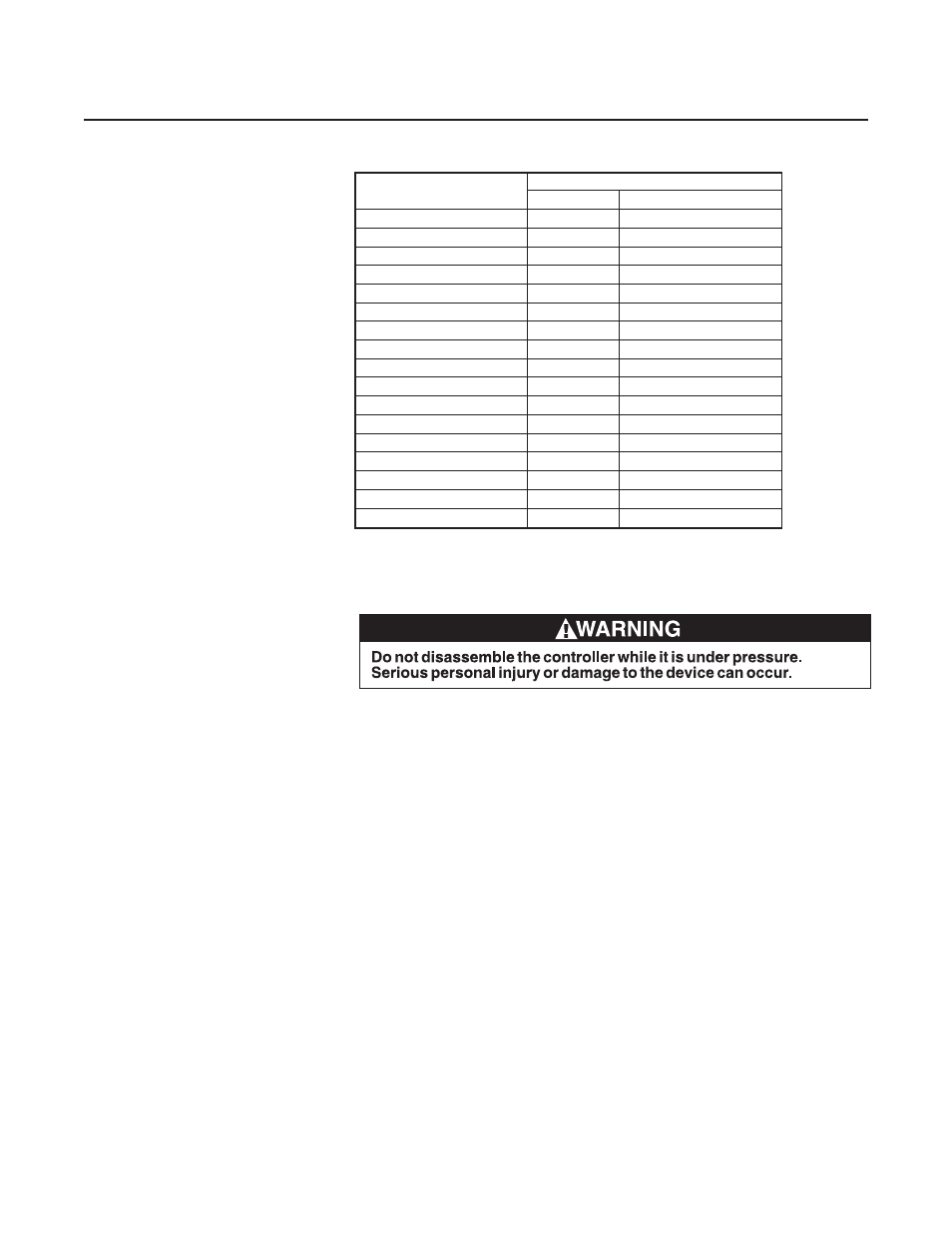

Orifice Size (inches)

Minimum Flow Rate (sccm)

32°F (0°C)

70°F (21.1°C)

0.0013

5.3

(5.7)

0.002

12.5

(13.5)

0.003

39.2

(42.2)

0.004

82.5

(88.9)

0.0055

190

(205)

0.007

374

(403)

0.010

748

(806)

0.014

1364

(1469)

0.020

2673

(2879)

0.032

6490

(6991)

0.048

12980

(13980)

0.062

22000

(2879)

0.078

31900

(34400)

0.093

42500

(45800)

0.120

69300

(74700)

0.1405

95,500

(103,000)

0.1495

108,200

(116,600)

Inlet Pressure = 10 psig

Outlet Pressure = 10 inches of water (0.4 psig) or less

Note: Flow Rate based on Nitrogen

5. I f the measured flow exceeds the value shown in Table 4-4 proceed to

step 7.

If the flow is less than expected, depressurize the controller and

disassemble the valve following Disassembly, Section 4-4 and proceed to

step 6.

Note: If the orifice size in use is unknown, it can be determined by:

Refering to Section 4-7, Orifice Sizing.Opening the control valve and

inspecting the orifice. Refer to Section 4-4, Disassembly

Consulting the factory with the full model number which is printed on the

front label of the controller and the order.

6.For orifice sizes 0.007" and greater add a 0.005" thick larger diameter

flow clearance spacer.

For orifice sizes less than 0.007" add a larger diameter 0.005" thick large

diameter flow clearance spacer and two 0.002" thick small diameter flow

clearance spacers. Refer to Figure 4-3b for spacer placement.

If this does not provide adequate flow, remove one at a time, 0.002"thick

small diameter spacers until the correct flow is achieved.

Assemble the valve following Assembly Section 4-4, utilizing the old socket

head cap screws and the 020 elastomeric O-ring. Apply inlet pressure and

zero volts to the valve.

Table 4-4 Orifice Capacities