Brooks, Mf series – Brooks Instrument Mfi Series User Manual

Page 41

4-3

Brooks

®

Mf Series

Section 4 Maintenance &

Troubleshooting

Installation and Operation Manual

X-TMF-Mfi-Mfx-MFC-eng

Part Number: 541B074AAG

August, 2009

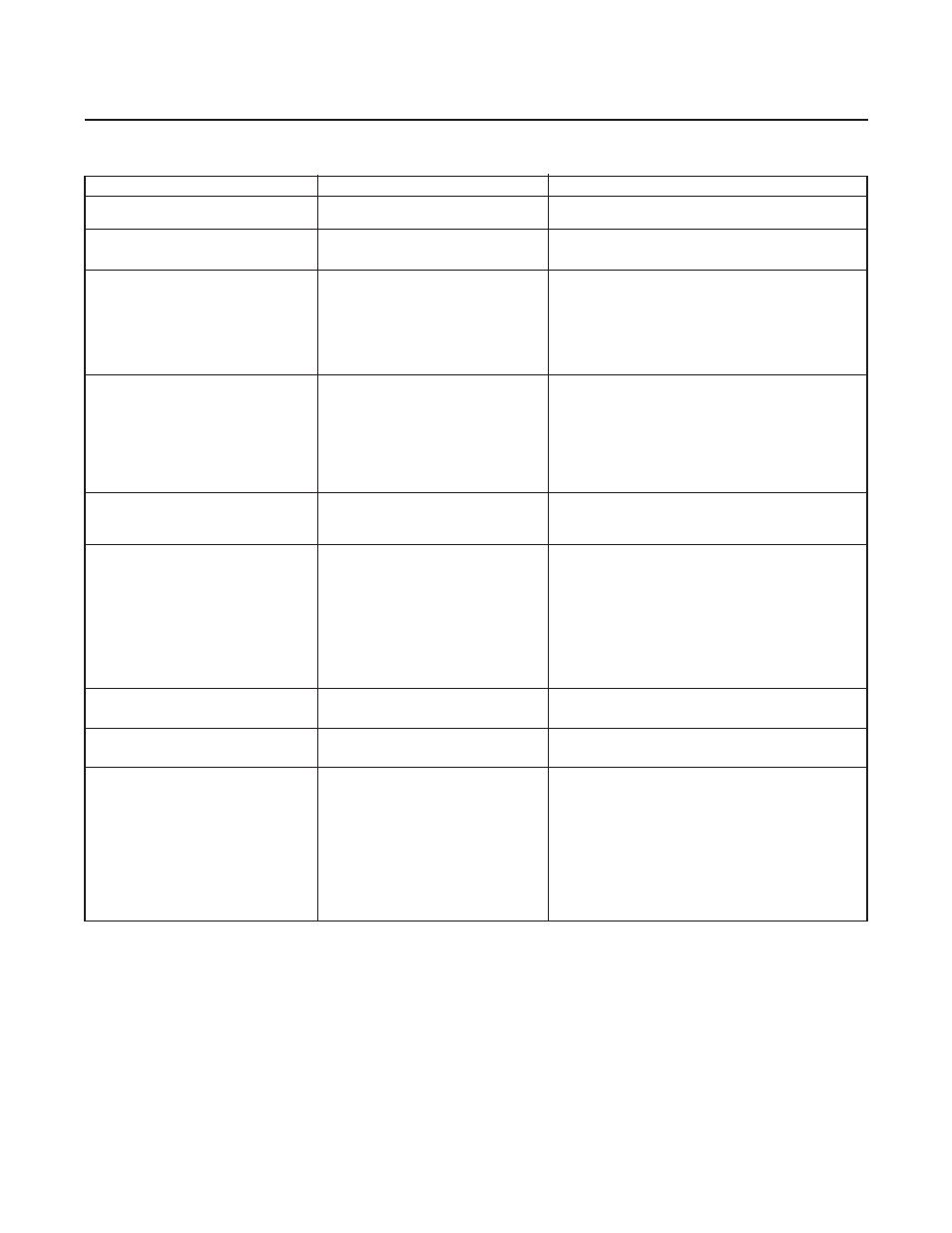

Table 4-1 Bench Troubleshooting

Trouble

Possible Cause

Check/Corrective Action

Actual flow overshoots controller setpoint

Anticipate potentiometer out of

Adjust anticipate potentiometer. Refer to Section 3-5.

by more than 5% full scale.*

adjustment

Output stays at zero and there is flow

Clogged sensor.

Clean sensor.Refer to cleaning, Section 4-2d.

through instrument

Output stays at zero regardless of setpoint/

Clogged control valve.*

Check TP3 with the setpoint at 100%. If the voltage is greater

flow and there is no flow through the

than 11V, disassemble and repair the control valve. Refer to

controller.

Section 4-4c.

Valve override input is grounded.*

Check valve override input (TB-2, Terminal 5).

Defective PC board.

Replace PC board. Refer to Section 4-4.

Output signal stays at +6.8 V or 26 mA

Valve stuck open or leaky.*

Clean and/or adjust control valve. Refer to cleaning procedure

regardless of setpoint and there is flow

and/or Section 4-4c.

through the instrument.

+15 V -28 Vdc applied to the valve

Check the valve override terminal (TB-2, Terminal 5).

override input.*

Defective PC board.

Replace PC board. Refer to Section 4-4.

Controller output signal follows setpoint at

Leaky control valve.

Disassemble and repair valve. Refer to Section 4-4c.

higher setpoints but will not go below 2% .*

Controller output signal follows setpoint at

Insufficient inlet pressure or pressure drop.

Adjust pressures, inspect in-line filters and clean/replace as

lower setpoints but does not reach

necessary.

full scale.*

Partially clogged sensor.

Check calibration. Refer to Section 3-4.

Partially clogged valve.

Disassemble and repair control valve. Refer to Section 4-4.

Valve out of adjustment.

Adjust valve. Refer to Section 4-4.

Valve guide spring failure.

Controller oscillates (see below).

Instrument grossly out of calibration. Flow is

Partially clogged sensor.

Clean sensor, refer to the cleaning procedure, Section 4-2d.

higher than desired.

Instrument grossly out of calibration. Flow is

Partially clogged restrictor.

Replace restrictor. Refer to Section 4-4.

lower than desired.

Instrument oscillates.

Pressure drop or inlet pressure excessive.*

Adjust pressures.

Oversized orifice.*

Check orifice size. Refer to Section 4-5.

Valve out of adjustment.*

Adjust valve. Refer to Section 4-4c.

Anticipate potentiometer out of adjustment.

Adjust anticipate potentiometer. Refer to Section 3-4.

Faulty pressure regulator.

Check regular capacity.

Defective PC board.

Replace PC board. Refer to Section 4-4.

*For controller only (Models Mf50/51/53).