Brooks, Mf series – Brooks Instrument Mfi Series User Manual

Page 48

4-10

Brooks

®

Mf Series

Section 4 Maintenance &

Troubleshooting

Installation and Operation Manual

X-TMF-Mfi-Mfx-MFC-eng

Part Number: 541B074AAG

August, 2009

3. For Mf51/61, place the end block O-ring in position and install the end

block with the 4 hex socket screws.

4. (Mfi Series only), press the lubricated sensor O-rings (25B) into the flow

controller body. Install the sensor assembly and secure with two screws

(37) and washers (38) and tighten.

5. Install the orifice (33) and its O-ring (25A) using a 3/8 nut driver. Insure

that the orifice is fully seated but do not overtighten.

6. Insert the valve preload spacers (28A), if used, into the valve cavity in

the flow controller body. Use care to preserve the correct order.

7. Place the spacers (28B) and springs (29) on the valve seat (32) in the

same order as noted in Step 8 of the disassembly. Screw the valve seat

(32) into the plunger (26). Tighten the assembly until there is no

looseness but do not overtighten.

8. Install the valve plunger assembly (26, 29, 28B and 32) on the preload

spacers (28A). Install air gap spacers (28A), if used, on top of the valve

springs.

9. Install the valve stem assembly (24), secure with the valve retaining

plate (23) and four hex socket screws (22). Install O-ring (1) onto valve

stem (24). When installing the screws they should first make light

contact with the plate which should be checked to insure that it makes

full contact around the stem assembly. Torque the screws securing the

valve retaining plate in a diagonal pattern (refer to Figure 4-1) to

17 in/lbs

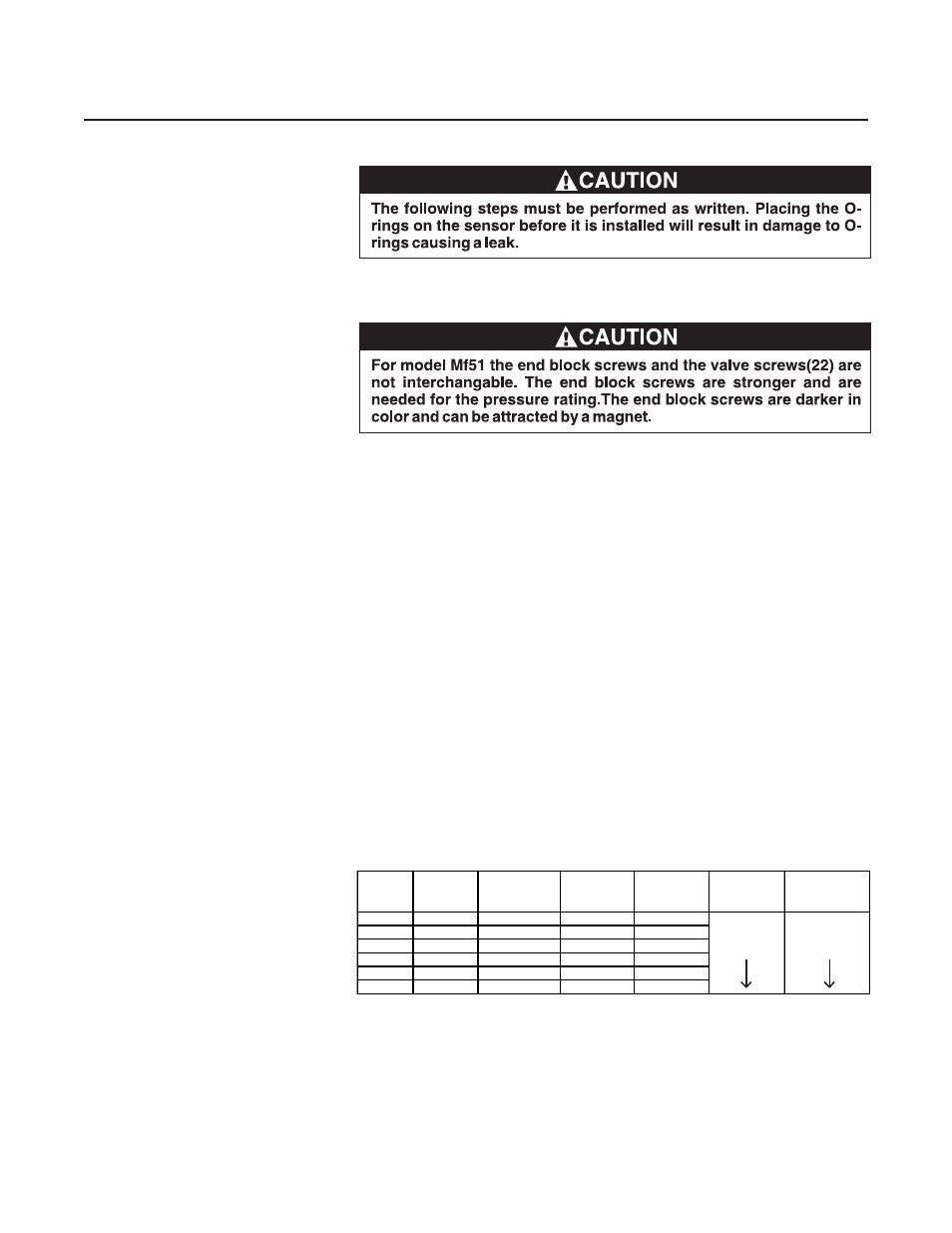

End

Valve

Electronics

Electronics

Block

Retaining

Sensor

Housing

Dome

Housing Cover

Model No.

Screws

Plate Screws

Screws

Screws (M4)

Nuts**

Screws

Mf50

N/A

17

15

25

1 1/2 Turns

Tighten until

Mf60

N/A

N/A

17

25

past finger

cover contacts

Mf51

30

17

10

25

tight

housing

Mf61

30

N/A

10

25

Mf53

133

17

10

25

Mf63

133

N/A

10

25

N/A = Not applicable

* The torque values listed should be used as a guide for assembly. The actual

torque may need to be adjusted depending on the lubrication of the mating

threads. It is recommended that the fasteners are used only one time. New

fasteners can be obtained as spare parts from the factory (refer to Section 5).

** This should be used only as a guide. It is recommended that the actual

number of turns, or torque, be determined empirically, using the actual cable.

Table 4-3 Mf Series Torque Requirements