Brooks, Mf series, Caution – Brooks Instrument Mfi Series User Manual

Page 21

2-3

Brooks

®

Mf Series

Section 2 Installation

Installation and Operation Manual

X-TMF-Mfi-Mfx-eng

Part Number: 541B074AAG

August, 2009

2-7 Gas Connections

Refer to Tables 5-1 through 5-4 for the available process connection types

and sizes. It is recommended that good tubing and piping practice be

followed. It is also recommended that for very low flows in meter size

Mf50's that tubing 1/4 or less be used and for flows over 10 slpm 3/8 tubing

be applied. Prior to installation, make certain all piping is clean and free of

obstructions. Install the piping in such a manner that permits easy removal

if the instrument is to be removed for cleaning or test bench

troubleshooting.

2-8 In-Line Filter

It is recommended that an Brooks in-line filter (refer to DS-5848 for

appropriate models/flows) be installed upstream from the instrument to

prevent the possibility of any foreign material entering the flow sensor or

control valve. The filtering element should be periodically replaced or

ultrasonically cleaned.

For Models Mf53/63, an in-line filter of 100 microns standard has been

installed upstream from the meter or controller to prevent the possibility of

any foreign material entering the flow sensor or control valve. The filtering

element should be periodically replaced or ultrasonically cleaned.

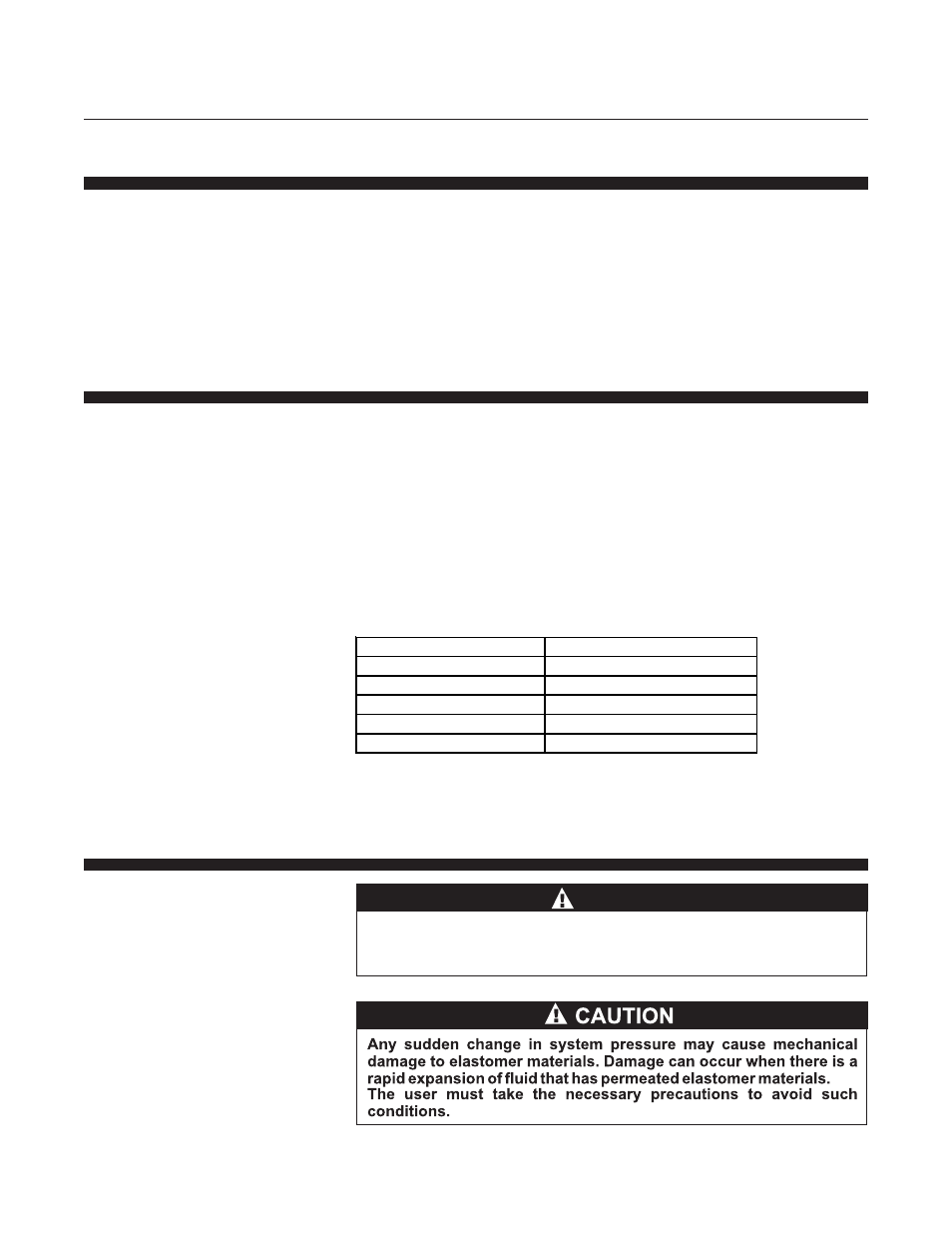

Note: The above lists the max. recommended porosity for each flow range.

It is recommended that the minimum micron porosity that does not limit the

full scale flow rate be used.

2-9 Installation (Refer to Table 1-4, Figure 1-4, 2-1 and Quick Start Instructions)

When installing the controller, care should be taken that no

foreign materials enter the inlet or outlet of the instrument. Do not

remove the protective end caps until time of installation.

CAUTION

Table 2-1 Recommended Filter Size

Maximum Flow Rate

Recommended Filter Size

100 sccm

1 micron

500 sccm

2 micron

1 to 5 slpm

7 micron

10 to 30 slpm

15 micron

30 to 100 slpm

30 micron