Quick-start operating instructions – Dynasonics TFXM Series Ultrasonic Multi-Channel Flow Meter User Manual

Page 5

Rev. 8/02

-1. 4-

TFXM

2. PIPE PREPARATION AND TRANSDUCER MOUNTING

A. The piping surface where the transducers are to be

mounted needs to be clean and dry. Remove loose scale,

rust and paint to ensure satisfactory acoustical bonds.

B. Apply a 3/8” [8 mm] wide bead of couplant lengthwise onto

the transducer faces. Place each transducer onto the pipe

ensuring proper linear and radial placement.

C. Tighten the transducer mounting straps sufficiently to

squeeze the couplant out along the flat surface of the trans-

ducer, filling the void between the transducer and the pipe

wall.

3. TRANSDUCER/POWER CONNECTIONS

A. If additional cable is to be added to the transducers, utilize

RG59 (75 Ohm) cable splices and ensure that both cables

are of equal length.

B. Refer to the TFXM Field Wiring Diagram, Figure 1.4, and

the terminal block labels for proper power and transducer

connections. Verify that the voltage level listed on the

product identification label—located on the side of the in-

strument enclosure– matches the power source where

connection is being made.

4. INITIAL SETTINGS AND POWER UP

A. Apply power to the instrument.

B. Verify that SIG STR is greater than 2% on all channels .

C. Verify that measured liquid SSPD is within 0.5% of the

configuration value on all channels.

D. Input proper units of measure and I/O data.

Startup

Connections

QUICK-START OPERATING INSTRUCTIONS

1.

Transducer mounting method

2.

Pipe O.D. (Outside Diameter)

3.

Pipe wall thickness

4.

Pipe material

5.

Pipe sound speed*

6.

Pipe relative roughness*

7.

Pipe liner thickness

8.

Pipe liner material

9.

Fluid type

10. Fluid sound speed*

11. Fluid viscosity*

12. Fluid specific gravity*

* Nominal values for these parameters are included within the TFXM

operating system. The nominal values may be used as they appear or

may be modified if exact system values are known.

TABLE 1.1

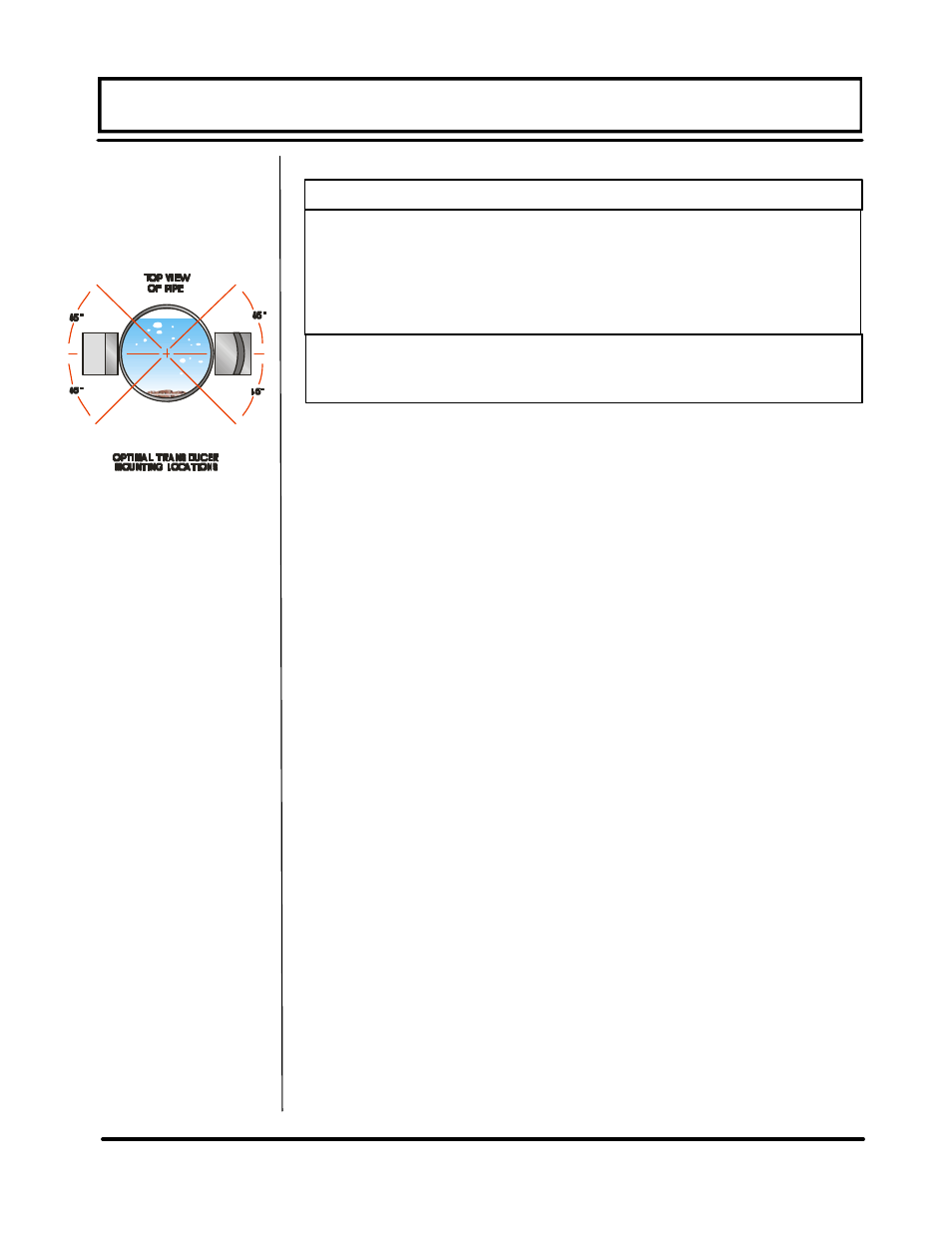

Figure 1.2

Transducer

Orientation