Part 2 - transducer positioning – Dynasonics TFXM Series Ultrasonic Multi-Channel Flow Meter User Manual

Page 36

Rev. 8/02

- 2.21 -

TFXM

3. Secure the transducer by tightening the stainless steel

strap. (Excessive pressure is not required. Apply just

enough pressure so that the couplant fills the gap between

the pipe and transducer.) If DOW 732, or some other sili-

cone RTV type sealant, was used ensure that no relative

movement between the transducer and pipe takes place

during the setting time and do not apply instrument power

for at least 24 hours. If Dow 44 or Dow 111 or an alternate

form of grease has been used as a couplant, setting time is

not necessary.

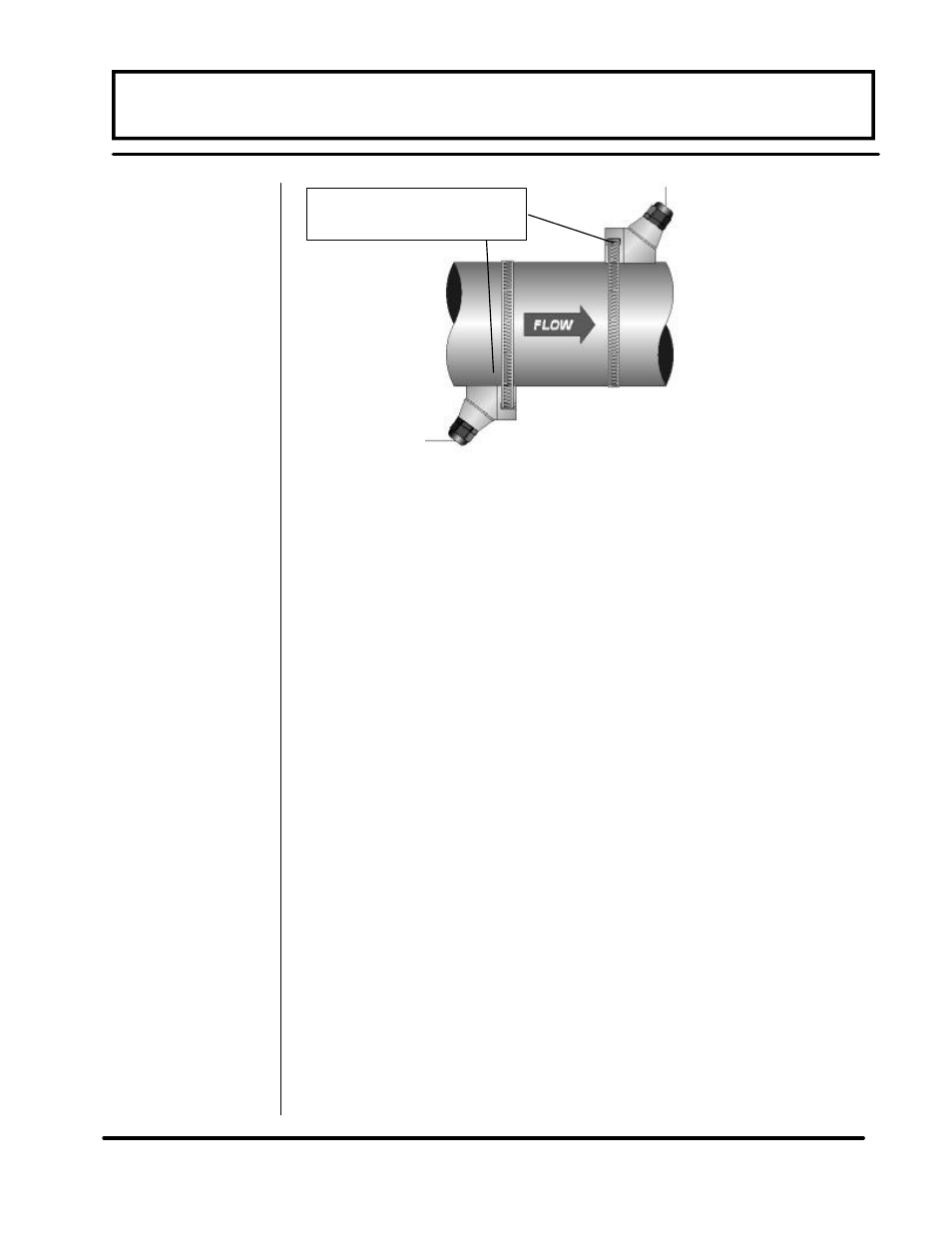

4. Mount the transducer in the same manner as the first, but at

the second mark on the pipe. Slide the transducer clamp

over the transducer and secure with the stainless strap. Re-

fer to Figure 2.9 for proper orientation.

NOTE: Since pipes larger than 20 inches (500 mm),

typically can be out-of-round by a substantial amount, it

is advised that the second transducer be left loose so

that it can be positioned at the location of greatest Signal

Strength. See Section 3 of this manual for Diagnostics

and Signal Strength Measurement. Maximum Signal

Strength can typically be obtained within 1 inch [25 mm]

of the calculated lineal distance.

PART 2 - TRANSDUCER POSITIONING

Figure 2.9 Z-Mode Transducer Mounting

Lineal measurements are

made from these lines.