Quick-start operating instructions – Dynasonics TFXM Series Ultrasonic Multi-Channel Flow Meter User Manual

Page 4

Rev. 8/02

-1. 3-

TFXM

This manual contains detailed operating instructions for all

aspects of the TFXM instrument. The following condensed

instructions are provided to assist the operator in getting the

instrument started up and running as quickly as possible. This

pertains to basic operation only. If specific instrument features

are to be used or if the installer is unfamiliar with this type of

instrument, refer to the appropriate section in the manual for

complete details.

1. TRANSDUCER LOCATION

A. In general, select a mounting location on the piping system

with a minimum of 10 pipe diameters (10 X the pipe inside

diameter) of straight pipe upstream and 5 straight

diameters downsteam. The installation location should

also be positioned so that the pipe remains full when the

liquid is flowing through it. On horizontal pipes the trans-

ducers should be located on the sides of the pipe. See

Figure 1.2. See Table 2.1 for additional configurations.

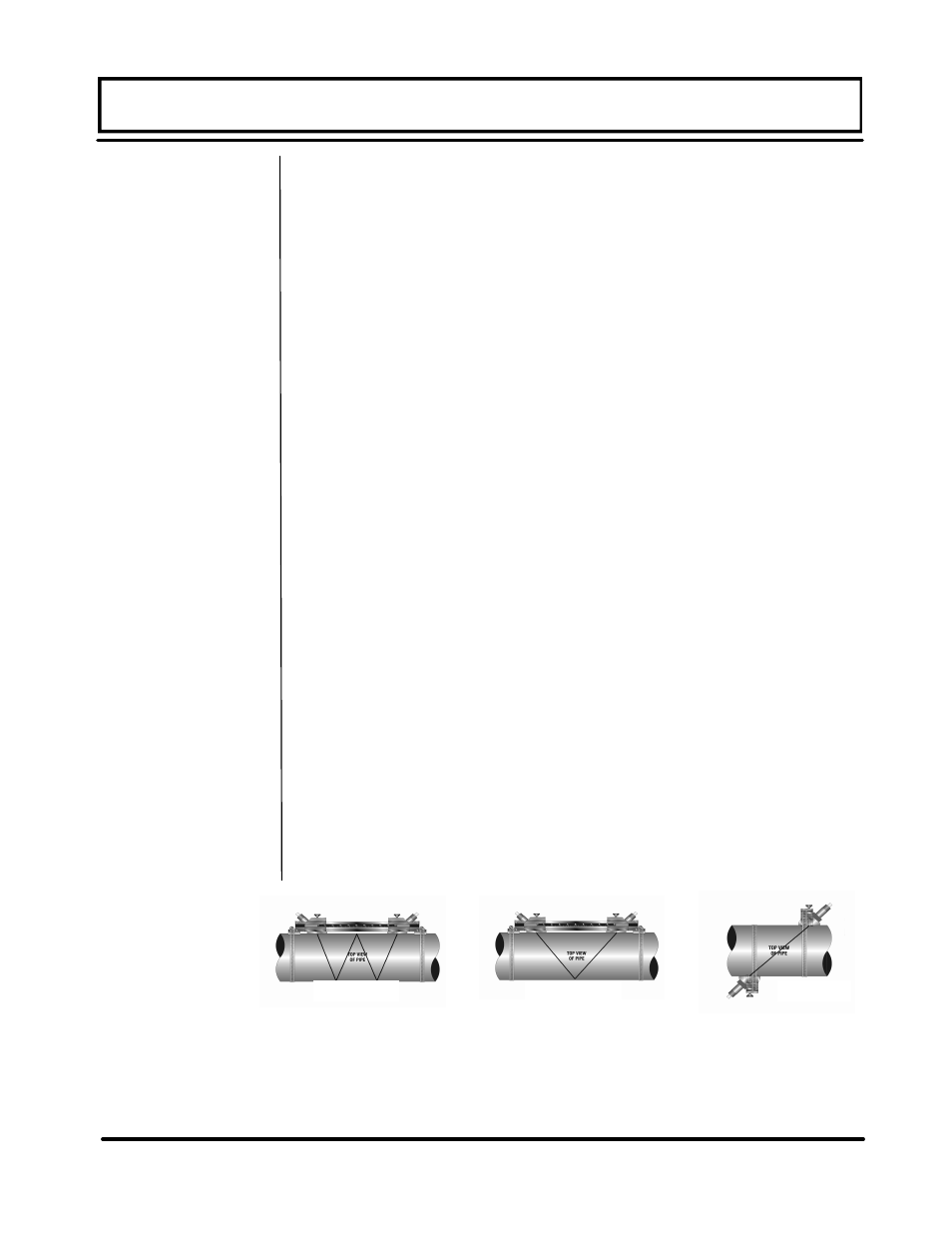

B. Select a mounting method, Figure 1.1, for the transducers

from Table 2.2, based on pipe size and liquid

characteristics. In General, select W-Mount for plastic and

steel pipes flowing clean, non-aerated liquids in the 1-6

inch [25-150 mm] internal diameter range. Select V-Mount

for pipes of all materials and most liquids in pipe sizes from

3-10 inches [75-400 mm]. Select Z-Mount for pipes larger

than 10 inches [400 mm].

C. For each measuring channel integrated into the TFXM, en-

ter the parameters listed in Table 1.1 via the TFXM keypad

or UltraLink software utility.

D. Record the value calculated and displayed as Transducer

Spacing/XDCR SPC.

Transducer

Location

QUICK-START OPERATING INSTRUCTIONS

W-Mount

V-Mount

Z-Mount

Figure 1.1