Dynasonics TFXM Series Ultrasonic Multi-Channel Flow Meter User Manual

Page 102

Description: Installation and Operation Manual Addendum

Series TFX Heat Flow Meter

Origin Date: 02/10/00

Revision: none

Revision date: none

Page 2 of 3

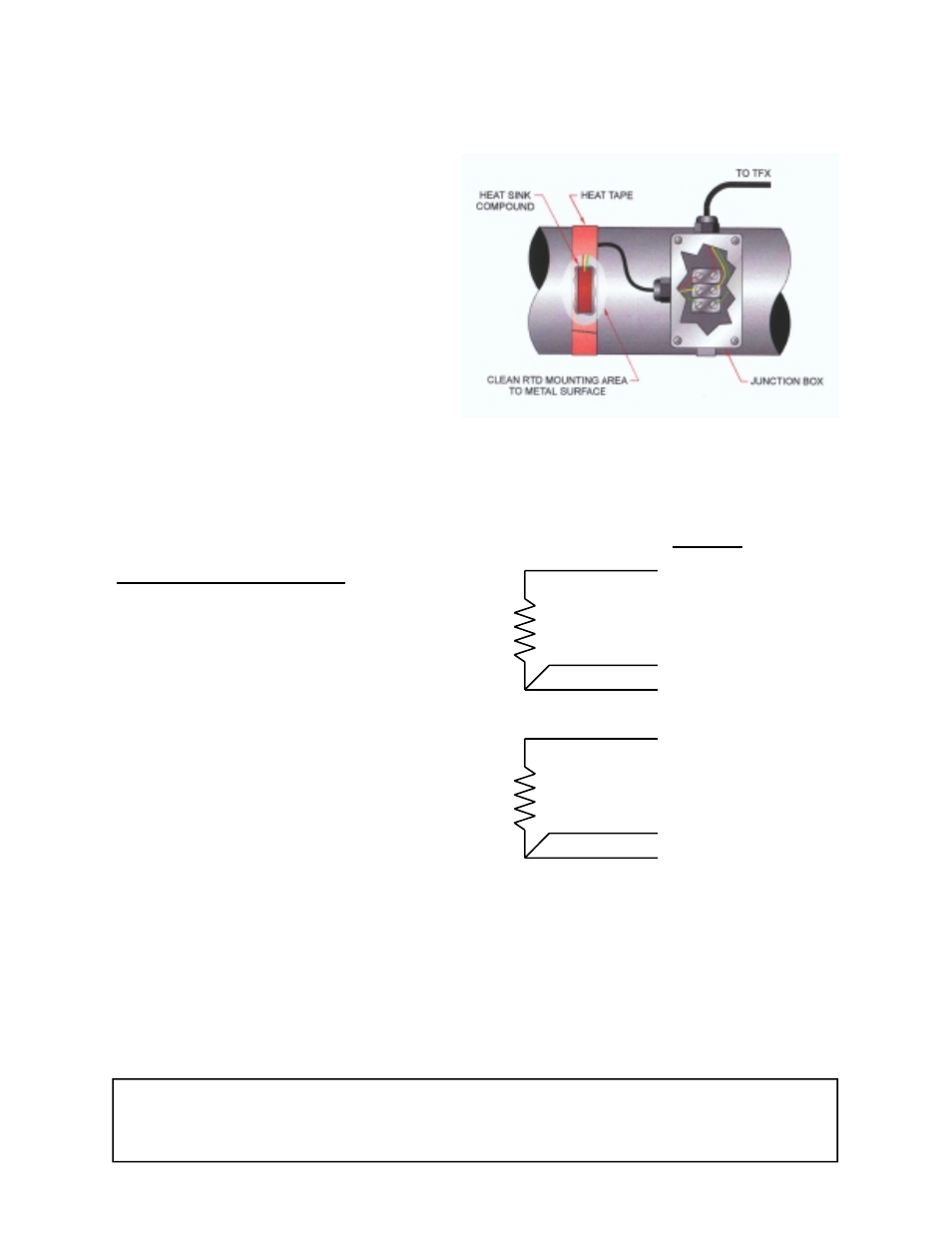

3. Place a small amount of heat sink

compound on the pipe in the RTD

installation location. See Figure 1.

Press the RTD firmly into the com-

pound. Fasten the RTD to the pipe

with the included heater tape.

4. Route the RTD wires to an electrical

junction box in close proximity to the

installation location. Secure the RTD

wires such that they will not be pulled

on or abraded inadvertently. Re-

place the insulation on the pipe.

5. Route a cable from the electrical

junction box back to the TFX flow-

meter. Connect the RTDs as illus-

trated in Figure 2. Note that the

SNS1 and DRV1 wires originate from

the same location on the RTD.

Transmitter Programming

1. The RTDs included with the TFX heat

delivered flowmeter have been factory

calibrated and are marked with an

identification as to which terminal, #1

or #2, the RTD has been calibrated.

If recalibration of the RTDs is required

or RTDs other than those supplied

with the TFX are being utilized, the

UltraLink software utility will be re-

quired. UltraLink can also be used to

configure all operating parameters of

the heat flow instrument.

2. To properly measure heat delivery,

the specific heat capacity of the liquid

must be entered. When a liquid is

chosen from the FL TYPE list, a de-

fault specific heat will be loaded. This default value is displayed as SP HEAT in the

BASIC MENU. If the actual specific heat of the liquid is known or if it differs from

the default value, press the ENTER key and modify the value. Press the enter key

to save the value. See the values listed in Tables 1 and 2 for specific values. Enter

a value that is the mean of both pipes.

RTD#1

REF1+2 & RTN

SNS 1

DRV 1

RTD#2

REF1+2 & RTN

SNS 2

DRV 2

TFX Module

Figure 2

Figure 1