Part 2 - transducer positioning, Transducer mounting – Dynasonics TFXM Series Ultrasonic Multi-Channel Flow Meter User Manual

Page 32

Rev. 8/02

- 2.17 -

TFXM

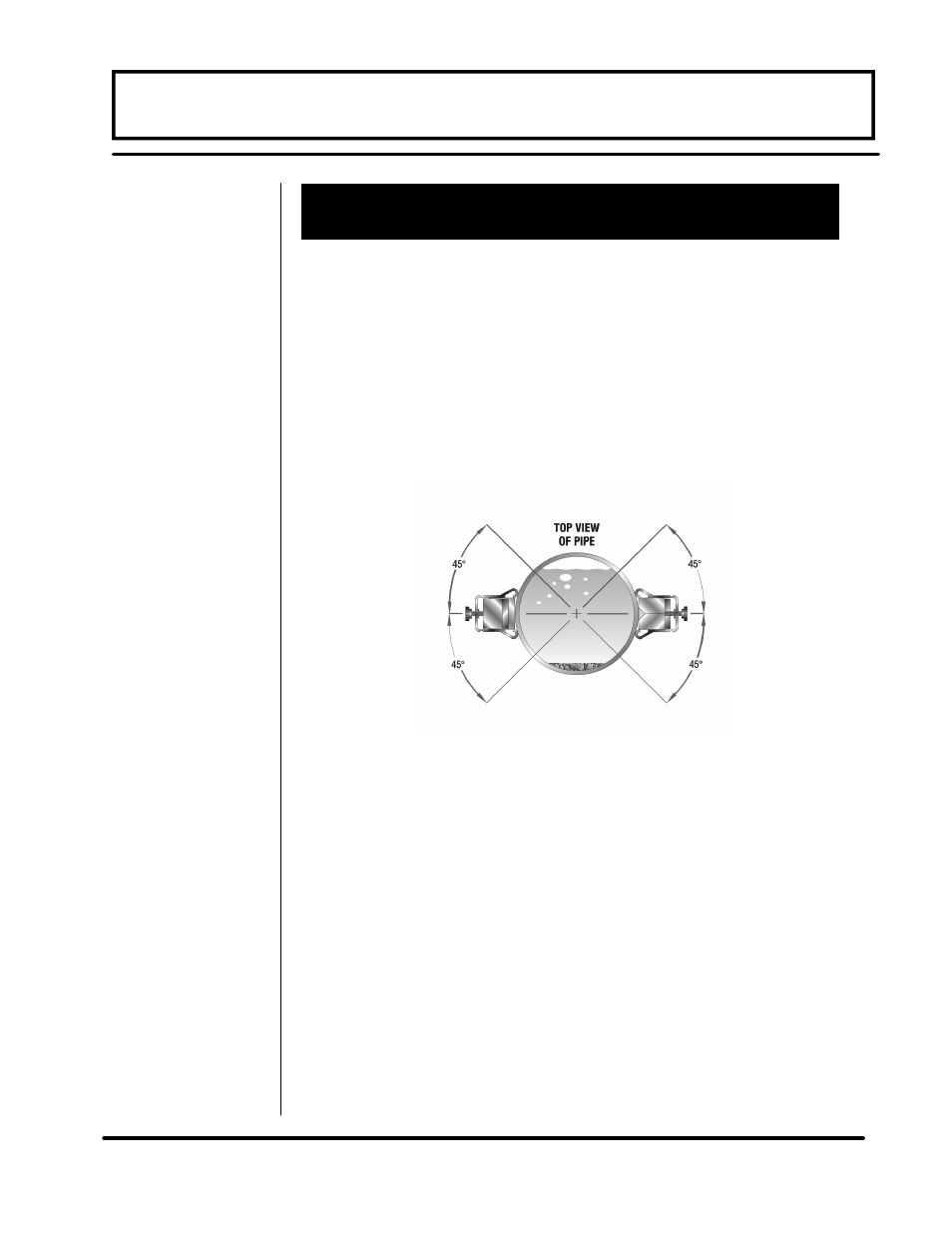

After selecting an optimal mounting location, Step 1, and suc-

cessfully determining the proper transducer spacing, Step 2, the

transducers can now be mounted onto the pipe.

The DTT transducers need to be properly oriented on the pipe

to provide optimum reliability and performance. On horizontal

pipes, the transducers should be mounted 180 radial degrees

from one another and at least 45 degrees from the top-dead-

center and bottom-dead-center of the pipe. See Figure 2.5.

Figure 2.5 does not apply to vertically oriented pipes.

Before the transducers are bonded to the pipe surface, two ar-

eas slightly larger than the flat surface of the transducer heads

must be cleaned of all rust, scale and moisture. Finish the sur-

face with some emery paper, and wipe the surface with a de-

greasing solvent such as trichlorethylene. Paint and other coat-

ings, if not flaked or bubbled, need not be removed. Plastic

pipes typically do not require surface preparation other than

soap and water cleaning.

PART 2 - TRANSDUCER POSITIONING

Figure 2.5 Transducer mounting locations on

horizontal pipe.

3. Transducer Mounting

Pipe

Preparation