Part 2 - transducer positioning – Dynasonics TFXM Series Ultrasonic Multi-Channel Flow Meter User Manual

Page 38

Rev. 8/02

- 2.23 -

TFXM

PART 2 - TRANSDUCER POSITIONING

5. Secure with the thumb screw. Ensure that the screw rests in

the counter bore on the top of the transducer. (Excessive

pressure is not required. Apply just enough pressure so that

the couplant fills the gap between the pipe and transducer.)

If DOW 732 or some other silicone RTV type sealant was

used, ensure that no relative movement between the trans-

ducer and pipe takes place during the setting time and do

not apply instrument power for at least 24 hours. If Dow 44

or Dow 111 or an alternate form of grease has been used as

a couplant, setting time is not necessary.

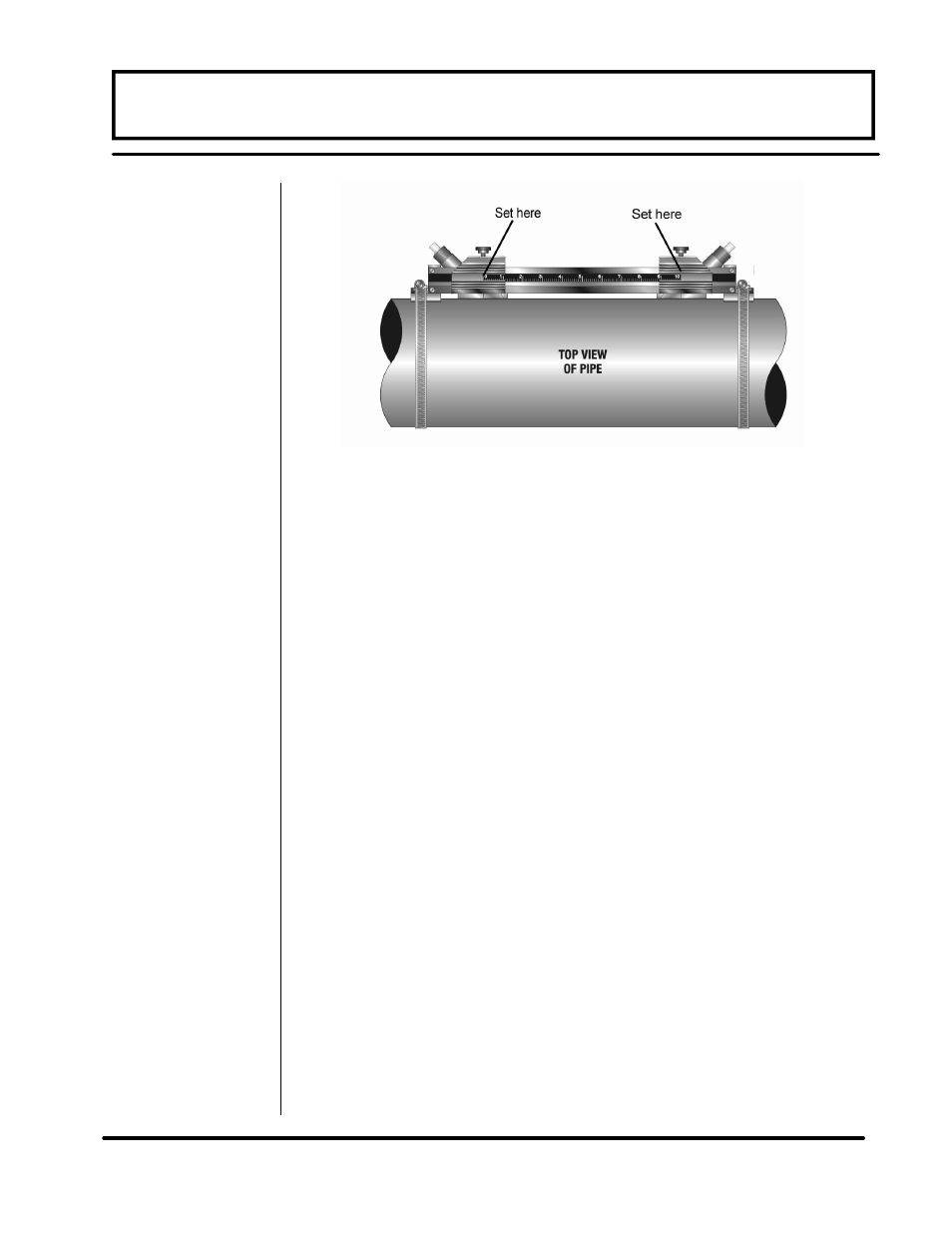

6. Place the second transducer in between the mounting rails

near the dimension derived in the Transducer Spacing sec-

tion. Read the dimension on the mounting rail scale. Slide

the transducer clamp over the transducer and secure with

the thumb screw.

Figure 2.11 Transducer Space Measurement