Datamax-O'Neil Class Series Programmer’s Manual User Manual

Page 245

Appendix J – General Purpose Input Output Ports

Class Series Programmer’s Manual

231

The GPIO Port allows convenient printer to applicator integration. Functions can be configured using the

menu system or via

Jumper settings are critical:

• Jumper settings allow internal or external power distribution to the applicator circuitry.

• Jumper settings allow + 5 or +24 VDC output signal levels.

WARNING

Failure to configure the card for the device(s) you are connecting may result in damage to the printer

and/or the applicator.

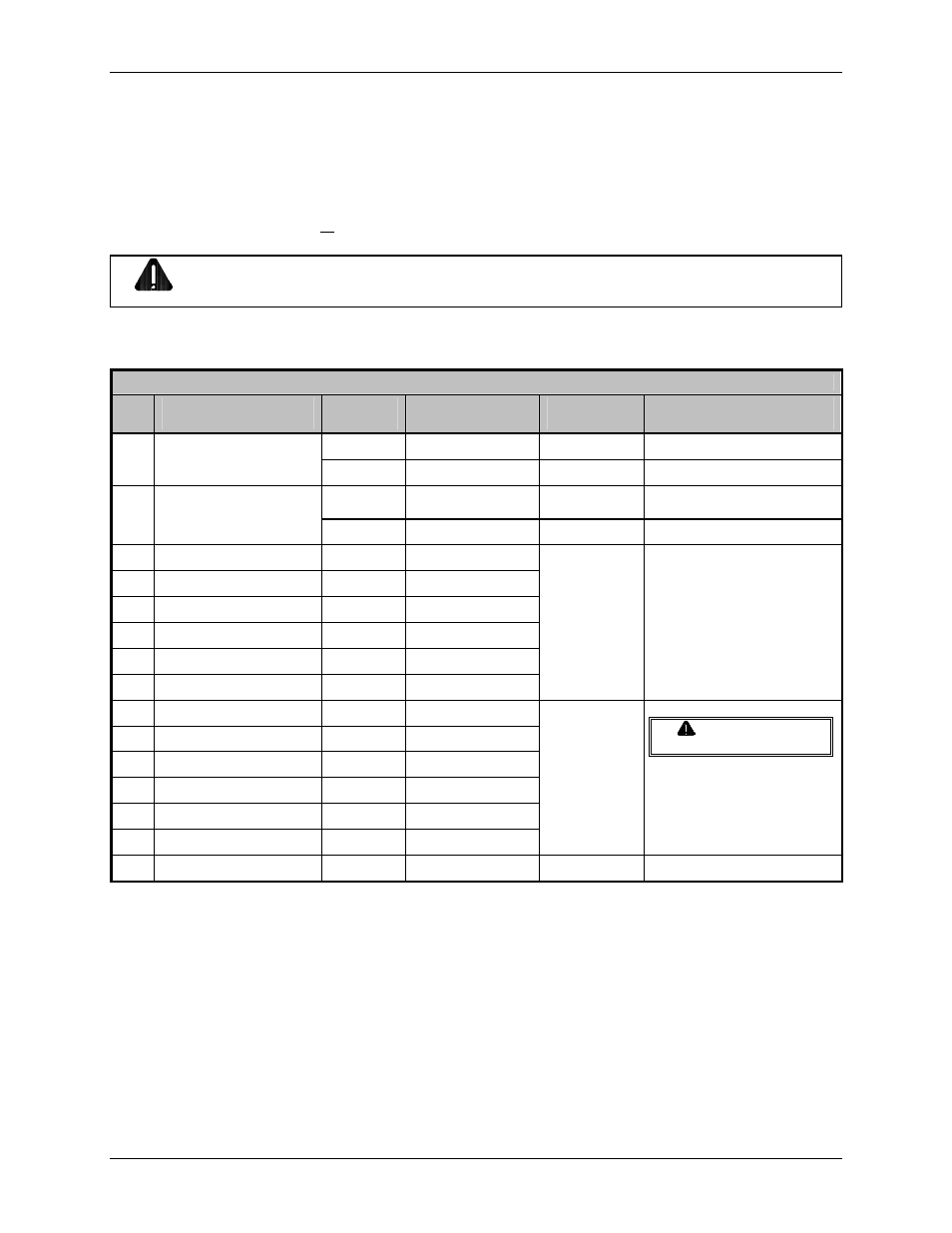

The table below details the GPIO Port functions, and configurable settings:

Applicator Interface Card GPIO Port (J2) Overview

Pin

#

Signal

Name

Signal

Direction

Active

Setting

Jumper

Placement

Function /

Description

Ground

Ground

JMP 7 ‘On’

Printer chassis ground is used

1

Ground (Configurable)

Open

Open

JMP 7 ‘Off’

Ground return must be supplied

Output

+5 VDC

JMP 8 ‘On’

Printer +5 VDC is used

(.5 amp max.)

2

+5 VDC (Configurable)

Open

Open

JMP 8 ‘Off’

+5 VDC must be supplied

3

Start Of Print

[3]

Input

Programmable

4 Slew

Label

Input

Programmable

5

Pause Toggle

Input

Low

6 Reprint

[2]

Input Low

7

+24 VDC (1.0 amp max.)

Output

+24 VDC

8 Ground

Ground

Ground

N/A

N/A

9

Ribbon Low

Output

Programmable

10 Service

Required

[1]

Output

Low

11

End Of Print

Output

Programmable

12

Media Out

Output

Low

13

Ribbon Out

Output

Low

14

Data Ready (DRDY)

Output

Low

JMP 9:

Pins 1 & 2 =

+5 VDC

– OR –

Pins 2 & 3 =

+24 VDC

See the WARNING

message, above.

When inactive, all output pins

will be pulled up to the voltage

determined by this jumper

setting.

15 Spare

Output N/A N/A

N/A

[1]

Evoked by occurrences listed under ‘Fault Messages’ in the A-Class Operator’s Manual.

[2]

Reprints the last label exactly, with no increment or time stamp changes; use it for error conditions. Always keeping this signal

LOW will result in non-stop printing.

[3]

If active with no current print job, “WAITING FOR DATA” is displayed. Specifying a quantity of 9999 while always

keeping this signal ‘ON’ will cause non-stop label printing, except in single label mode (see Imaging Mode, Section 4.2.5 of

the A-Class Operator’s Manual), which will cause the printer to stop between labels.