Datamax-O'Neil Class Series Programmer’s Manual User Manual

Page 19

Overview

Class Series Programmer’s Manual

5

Commands are available for retrieving stored label formats, updating data, and adding new data. These

techniques are used for increasing throughput. See

Command ‘s’.

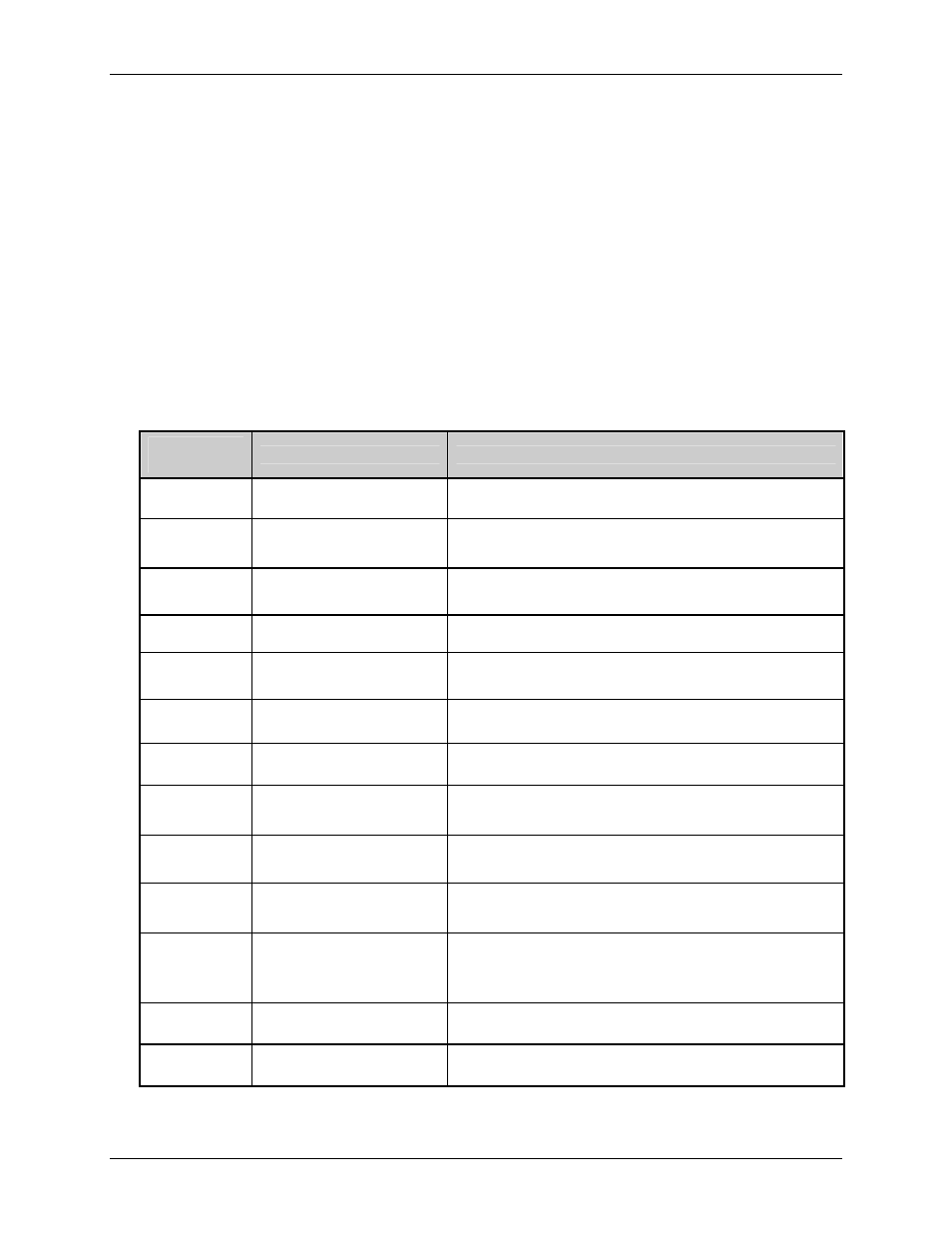

Typical commands used in the various stages shown above are listed in the tables that follow.

Configuration Commands

The following table lists some commands useful in controlling printer configuration. These

commands are generally effective only for the current power-up session; toggling power restores the

default configuration. See

default power-up configuration and saving objects in printer Flash memory can reduce the data

transmitted for each label and therefore improve throughput.

Configuration

Command

Name

Function

Set Date and Time

Set Date and Time

Set Double Buffer Mode

Force generation of multiple memory copies of label format;

usually not used

Set Continuous Paper Length Must be 0000 for gap media; not used for reflective media

Set Edge Sensor

Setup for gap or registration hole type stock

Set Present Distance

Determines label stop position, head relative.

sensor relative equivalent command, older models

Configuration Set

Determines default power-up configuration

Send Form Feed

Sets the stop position of the printed label

Set Maximum Label Length

Length to search for next gap or reflective mark; not used

with continuous media

Set to Metric Mode

Subsequent measurements interpreted in metric (most units

mm/10). Label equivalent command can be used

Set to Inch Mode

Subsequent measurements interpreted in inches, most units

in/100, Label equivalent command can be used

Set Start of Print Position

Effect is not on label immediately following command since

media position is at Start of Print between labels;

default position relative

± 64 in/100 maximum deviation

Set Feed Rate

Blank label movement speed

Software Switch

Enable optional hardware, cutter, present sensor