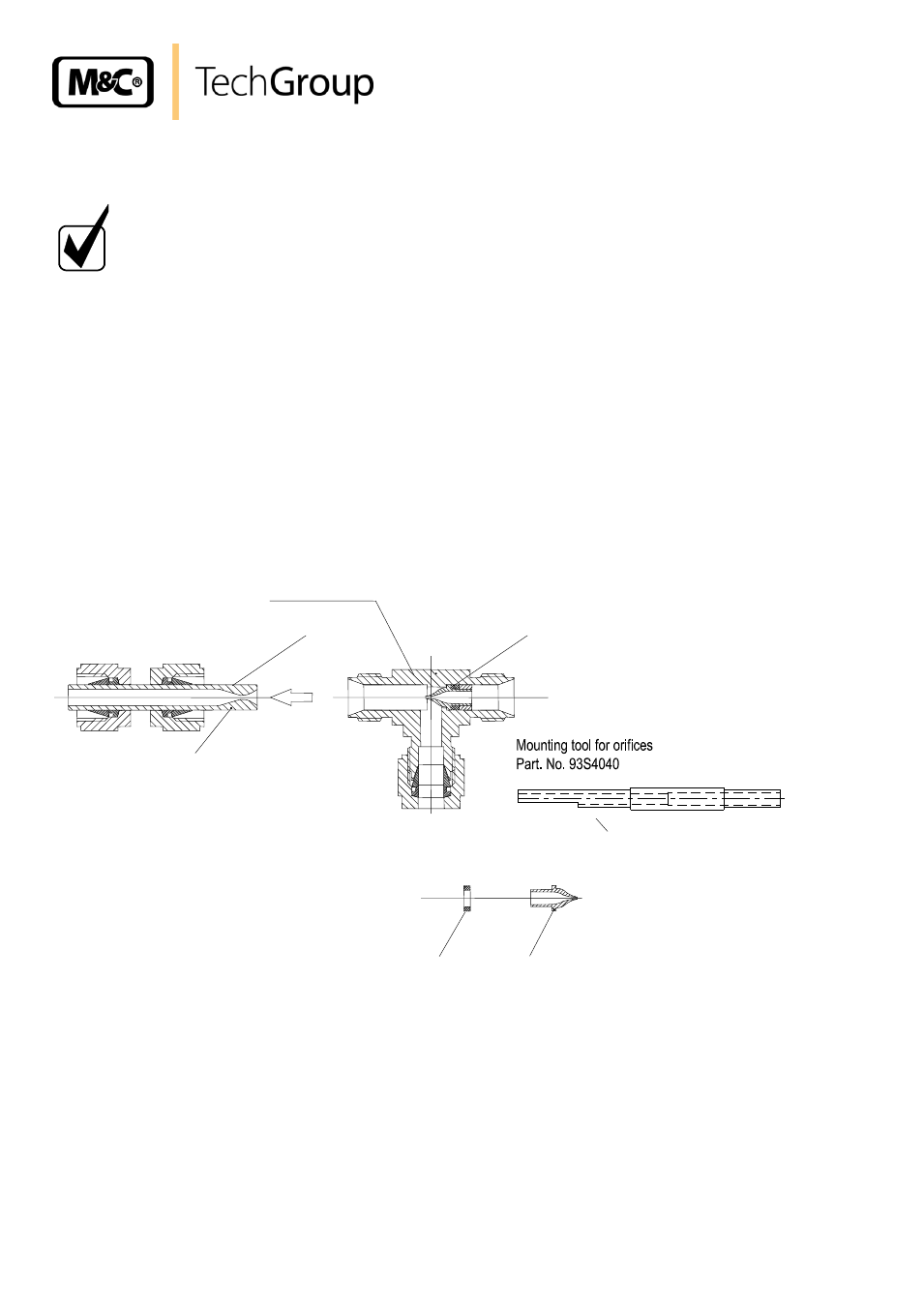

Figure 18, Bypass injector unit with o-ring ( 180°c-version ) – M&C TechGroup SP2000H_DIL_BR Operator's manual User Manual

Page 32

32

Gas sampling and gas conditioning technology

2-1.1.7-ME

16.3.1

CHANGE AND CLEANING OF THE BYPASS INJECTOR (180°C VERSION)

N O T E !

For cleaning the injector of the 180°C-vesion it is not necessary to remove it

out of the Bypass-T. Clean the nozzle mechanically or put the complete

cross into an ultrasonic bath. For the 320°C-version do not clean the com-

plete cross in an ultrasonic bath because the graphite packing could be de-

stroyed.

A cleaning with compressed air has to be carried out from the sample outlet

side (jet pipe).

We recommend the following steps for the change of the bypass injector:

Unscrew the jet pipe (pos. 2) from the Bypass-T;

Push out the injector nozzle from the opposite side (tool pos. 3, Fig. 18) and change it with

sealing;

Push the injector into the T up to the block and press it tightly. Use the mounting tool.

16.3.2 CHANGE OF THE O-RING AT THE BYPASS INJECTOR (180°C-VERSION)

Figure 18 shows the injector in the 180°C-version.

nozzle

O-Ring

Part No.: 93S4000

Injector complete, SP2000-H/DIL

Mounting tool

Part No.: 93 S 4040

Jet-pipe

Bypass-T

Pos.1:

O-Ring for nozzle

Figure 18

Bypass Injector unit with o-ring ( 180°C-Version )

We recommend the following steps:

Unscrew the jet pipe (pos. 2) from the Bypass-T;

Push out the injector nozzle from the opposite side (tool pos. 3, Fig. 18);

Remove the thrust collar and the o-ring;

Push new o-ring on the nozzle;

Put on the thrust collar;

Push the injector into the T up to the block and press it tightly. Use the mounting tool.