Figure 17, Bypass-t with injector and o-ring (180°c version) – M&C TechGroup SP2000H_DIL_BR Operator's manual User Manual

Page 31

31

Gas sampling and gas conditioning technology

2-1.1.7-ME

Please change the packing as follows:

Loosen union nut 3 and remove the jet pipe;

Loosen nut 4 and remove the dilution tube connection;

Push out the injector with the tool (Pos. 3) from the opposite side (jet pipe);

Remove the thrust collar from the nozzle;

Remove the graphite rings;

Push on the nozzle and the 3 new graphite rings;

Replace the thrust collar;

Re-install the injector with the tool. Push it up to block and press it tightly.

W A R N I N G !

The Swagelok

®

fittings must be carefully tightened to avoid damag-

ing the internal components!

16.3

REMOVING THE BYPASS-T USING OPTION ..B/..BR (180°C VERSION)

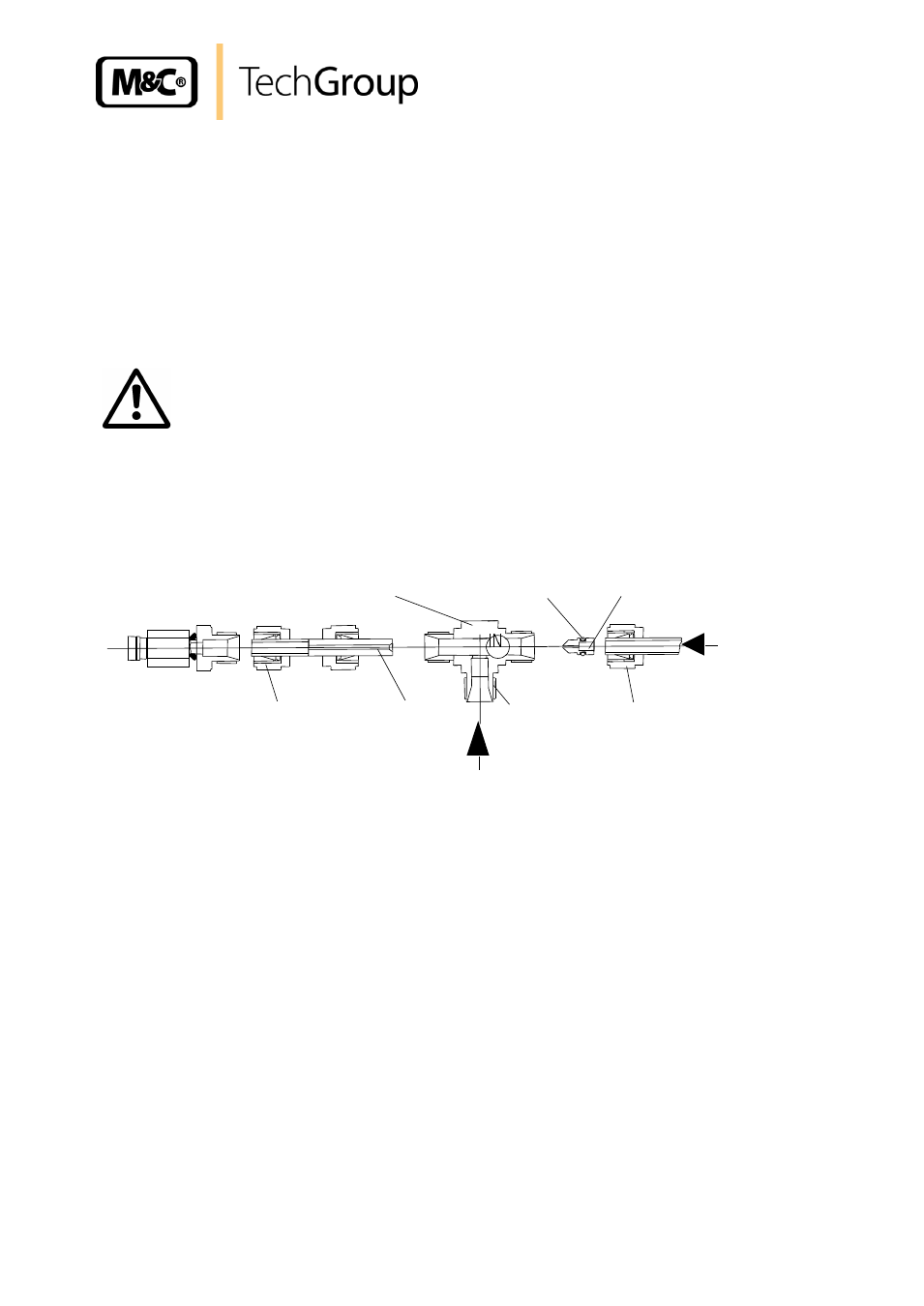

For maintenance and cleaning the Bypass-T can be dismantled completely. The figure below shows

the scheme of the Bypass-T.

Injector nozzle

O-ring

Bypass-T

Jet pipe

Union nut 2

Nut 1

Nut 3

Sample gas

Dilution gas

Figure 17

Bypass-T with Injector and o-ring (180°C version)

Dismantle the Bypass-T as follows:

Remove probe insulating cover (see 16.1);

Remove all pipe connections on Bypass-T. These are:

-

Bypass inlet union nut 1

-

union nut 2 (sample outlet side)

-

union nut 3 (sample inlet).

The Bypass-T is now ready for further maintenance and repair.