Technical data, 8technical data – M&C TechGroup SP2000H_DIL_BR Operator's manual User Manual

Page 13

13

Gas sampling and gas conditioning technology

2-1.1.7-ME

8

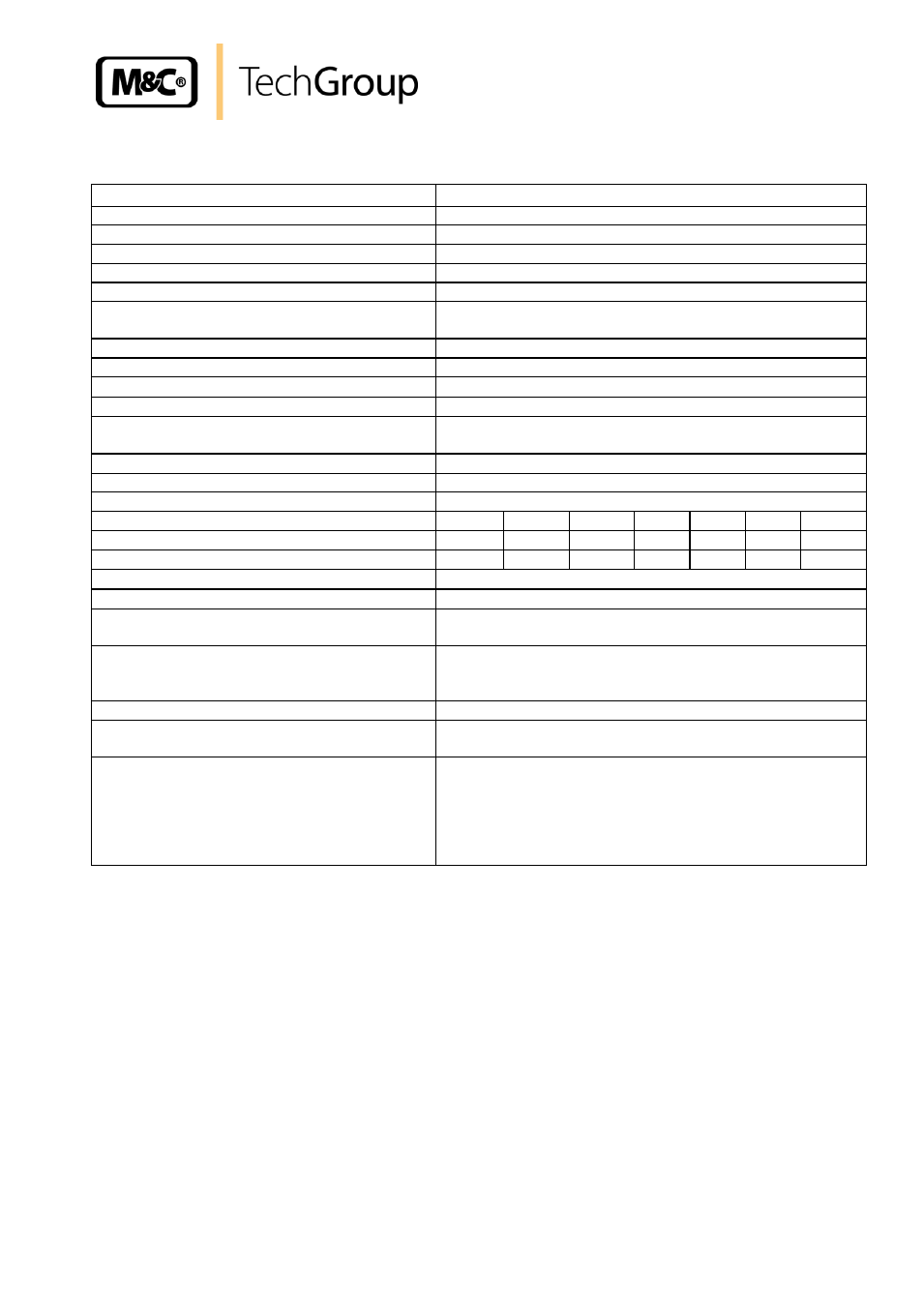

TECHNICAL DATA

Technical data SP series

®

Dilution probe version SP2000H/DIL ..

Weather protective cover

Yes

Electrical connection

Terminals; max. 4 mm²

Degree of protection of terminal box

IP54

EN60529

Mains supply

230V 50/60Hz, 800W

or

115V 60Hz, 800W

(fuse 10A)

Material of medium contacted parts

Stainless steel 1.4571, 1.4404, quartz glass, FPM, graphite

Ambient temperature

Thermostat: +5°C to 60°C

PT100, thermocouple: +5°C to 80°C

Operating temperature

0-180°C* alternatively 0-320°C

Ready

after 2 h

Temperature status alarm

/

30°C to T

NOMINAL

*

Alarm contact rating

250V 3A AC, 0:25A DC

Sample gas outlet connection

1/4"-NPT internal, for max. 10mm pipe union

for version /H320 = pipe union ø

i

6mm*

Test gas back-flushing connection

for version /R pipe 6mm o.d.*

Filter space volume

120 ml

Weight

about 20 kg

Orifice type

a

b

c

d

e

f

g

Dilution factors

1)

500:1

200:1

100:1

50:1

30*:1

20:1

10:1

Sample gas volume [Nl/hr]

2)

1.4

2.7

5.5

11

19*

28

55

Dilution factor adjustment range

with dilution gas supply pressure setting -5% - +30%

3)

Dilution gas volume injector version I or II

I: 480-600 Nl/hr*, optional II: 1800

–3000 Nl/hr

Dilution gas supply pressure upstream of pres-

sure regulator

Min. 4.5 bar, max. 16 bar

Bypass injector/B/BR:

Supply pressure

– gas consumption – sample

gas volume

about 2 bar : Propellant ca. 300 l/hr : Sample gas about 150

l/hr

Process pressure

0.9 to 2 bar abs. at constant pressure

Influence of process temperature variations

No influence due to operation independent of process tem-

perature

Influence of pressure change

Influence negligible at pressure changes

≤ 200mbar other-

wise proportional to pressure changes.

Calibration of probe must be performed under process con-

ditions or pressure correction must be implemented. Op-

tional connection for pressure measurement / compensation

1/4“ NPT i.

* Standard, specify other values when ordering, intermediate values can also be specified.

1)

Values with injector I (higher dilution rates with injector II possible),

2)

at about 3 bar (downstream of supply pressure regulator) dilution gas,

3)

-

5% however, not for orifice “g”