Function, Figure 6, Gas flow schematic – M&C TechGroup CSS Series Operator's manual User Manual

Page 16: 9function, Figure 6 gas flow schematic

16

Gas sampling and gas conditioning technology

4-1.1-ME

9

FUNCTION

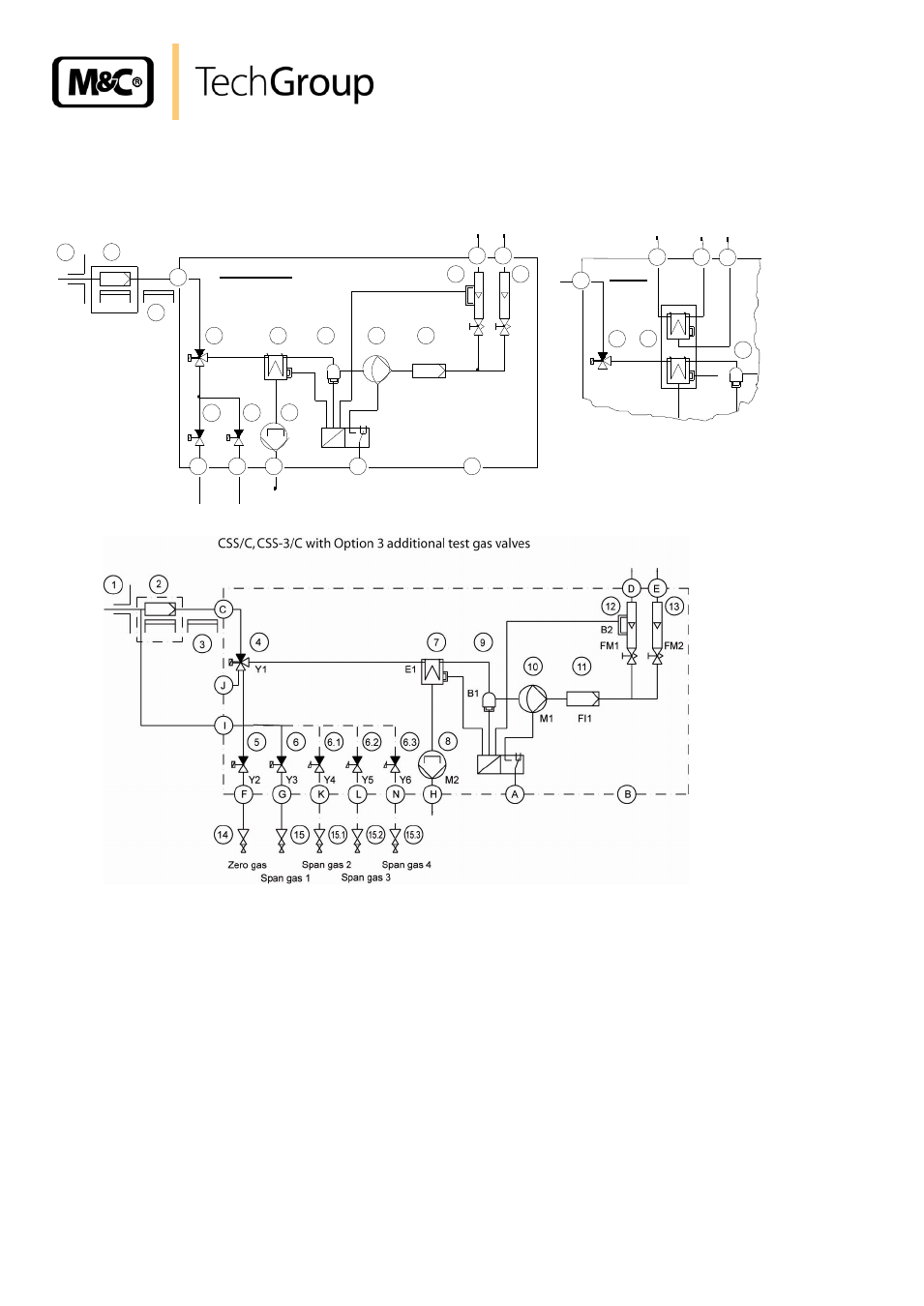

The gas flow schematic of the CSS is shown in the following illustration.

13

12

11

10

9

7

4

5

8

6

3

2

1

F

G

H

D

E

C

FM1

FM2

A

B

B2

FI1

M1

B1

E1

Y1

Y2

Y3

M1

CSS; CSS-3

Zero

gas

Span

gas

9

7

4

C

B1

E1

Y1

M

K

L

CSS-2

3

L

F

K

13

12

11

10

Zero gas Span gas 1

9

7

4

5

8

6

14

15

2

1

G

H

D

E

C

FM1

FM2

A

B

B2

Fl1

M1

B1

E1

Y1

Y2

Y3

M2

I

Span gas 2

15.1

Y4

6.1

Span gas 3

Y5

6.2

Span gas 4

Y6

6.3

N

15.2

15.3

J

CSS/C; CSS-3/C with option 03G9030 (a)

Figure 6 Gas flow schematic

Principally, there are two main ways for gas to enter and flow through the CSS:

- sample gas flow (C, 4, 7, 9, 10, 12 and 13, D and E);

(version CSS-2 additional: M, 7, K);

- test gas flow (F or G, 5 or 6, 4, 7, 9, 10, 11, 12 and 13, D or E)

(Version CSS.../C: F or G, 5 or 6, I, 2, C, 4, ... see above).

The gas sample pump (10) transports the sample gas via the gas sample probe, consisting of a sam-

ple tube (1) and a filter (2), to the CSS. The heated sample line (3) is connected at the sample gas

inlet (C). In order to prevent early condensation of the sample gas, components (2) and (3) are

heated.

In the measuring mode, the 3-way solenoid valve (4) allows the flow to the gas cooler (7).

The dew point of the gas is maintained at a stable value of +5°C +/- 0,1 °C (for further specifications

see appendix).