5) support – Reznor SCE Unit Installation Manual User Manual

Page 9

Form RZ-NA I-SCE, Mfg #207697 Rev 7,

Page 9

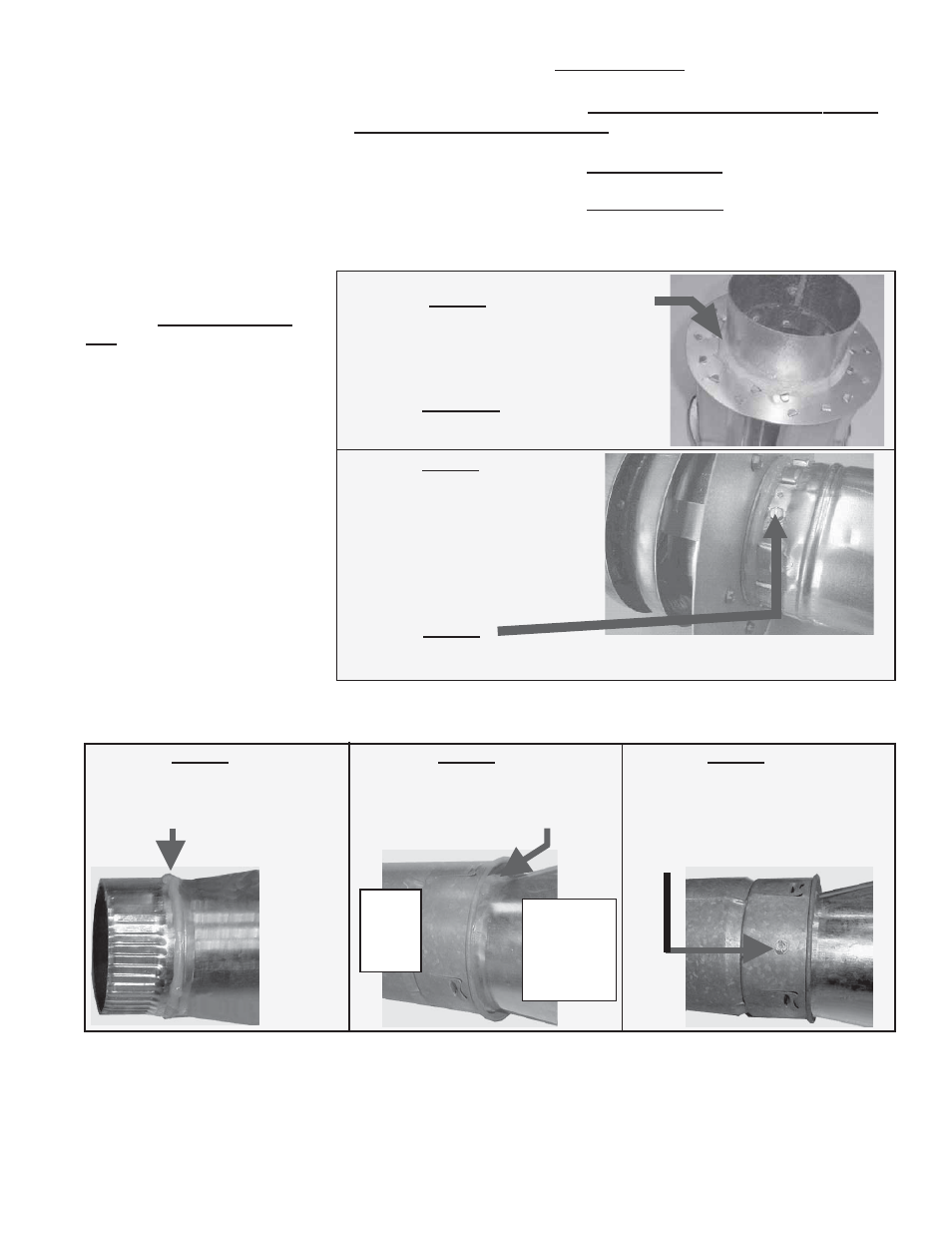

FIGURE 8 - Follow STEPS to

join Double-Wall (Type B)

Pipe and the Vent Terminal

Cap (horizontal or vertical)

Figure 8 - STEP 1

Place a continual 3/8” bead of silicone sealant

around the circumference of the vent cap col-

lar. This will prevent any water inside the vent

cap from running down the double-wall pipe.

Do STEP 2 immediately following STEP 1.

Figure 8 - STEP 2

Insert the collar on the vent cap inside the

inner wall of the double-wall pipe. Insert

as far as possible. Add additional silicone

sealant to fully close any gaps between

the vent cap and the double wall pipe.

This is necessary to prevent water from

entering the double wall pipe.

Secure the vent cap to the double-wall pipe by drilling and inserting a 3/4” long

sheetmetal screw into the vent cap collar. Do not overtighten screw.

Figure 8 - STEP 3

(NOTE: Pipes and vent caps may

not look exactly as shown in the

illustrations. Instructions apply to

both horizontal and vertical vent

kits.)

FIGURE 9 - Follow STEPS

to join the Double-Wall (Type

B) Pipe to the Taper-type

Reducer that Joins it to the

Single-Wall or Category III

Vent Run

Figure 9 - STEP 1

On the taper-type reducer, place a con-

tinual 1/4” bead of silicone sealant

around the circumference.

Figure 9 - STEP 2

Insert the collar of the reducer into the

inner pipe of the double-wall pipe until

the bead of sealant contacts the inner

pipe creating a sealed joint.

Figure 9 - STEP 3

Spaced equally around the double-wall

pipe, drill three small holes below the

sealant ring. Insert 3/4 inch long

sheetmetal screws to secure the joint. Do

not overtighten screws.

Make this connection a maximum of 6" (152mm) from the concentric adapter box.

5" I.D.

Double-

Wall

Pipe

6" to 5" or

7" to 5"

Taper-

Type

Reducer

Do STEP 2

immediately

following

STEP 1.

• To seal joints in the single-wall combustion air pipe, secure slip fit pipe connections

using sheetmetal screws or rivets. Seal all joints with aluminum tape or silicone sealant.

•

To seal joint in the terminal section of double-wall vent pipe (allowed ONLY ABOVE

the concentric pipes on a VERTICAL vent, follow the pipe manufacturer’s instructions

for joining and sealing double-wall vent pipe sections.

• When joining the terminal section of double-wall vent pipe to the vent cap, follow the

illustrated step-by-step instructions in FIGURE 8.

When joining the terminal section of double-wall vent pipe to a single-wall or Cat-

egory III vent pipe run, follow the illustrated step-by-step instructions in FIGURE 9.

5) Support

Support horizontal runs every six feet (1.8M). Support vertical runs of type "B" double-wall

or Category III vent pipe in accordance with the requirements of the pipe manufacturer.

Support single-wall vertical pipe in accordance with accepted industry practices. Do not rely

on the heater or the adapter box for support of either horizontal or vertical pipes. Use non-

combustible supports on vent pipe.

NOTE: The double-wall vent

terminal pipe does not attach to the

concentric adapter box and must be

supported during installation.