Uncrating (cont'd), Clearances and location – Reznor SCE Unit Installation Manual User Manual

Page 4

Form RZ-NA I-SCE, Page 4

4. Uncrating (cont'd)

For best results, the heater should be placed with certain rules in mind. In general, a unit should

be located from 8 to 12 ft (2.6 to 3.6M) above the floor. Units should always be arranged to blow

toward or along exposed wall surfaces, if possible. Where two or more units are installed in the

same room, a general scheme of air circulation should be maintained.

Suspended heaters are most effective when located as close to the working zone as possible, and

this fact should be kept in mind when determining the mounting heights to be used. However,

avoid directing the discharged air directly on the room occupants.

Partitions, columns, counters, or other obstructions should be taken into consideration when

locating the unit heater so that a minimum quantity of airflow will be deflected by such obstacles.

When units are located in the center of the space to be heated, the air should be discharged

toward the exposed walls. In large areas, units should be located to discharge air along exposed

walls with extra units provided to discharge air in toward the center of the area.

At those points where infiltration of cold air is excessive, such as at entrance doors and shipping

doors, it is desirable to locate the unit so that it will discharge directly toward the source of cold

air from a distance of 15 to 20 feet (4.5 to 6 M).

CAUTION: Do not locate the heater where it may be exposed to water

spray, rain, or dripping water.

Location

Vent Terminal/Combustion Air Inlet

Kit with Concentric Adapter Box -

Required for All Installations

To protect the unit during shipping, blower models have special supports that must be

removed before installation. Follow these instructions to remove:

Blower Support Legs - Remove the blower support legs and screws.

Motor Shipping Block - Remove the wooden block located under the motor bracket. Find

the two rubber pads shipped in the instruction envelope. Place these pads on the ends

of the motor bracket bolts.

Motor Shipping Plate - Units that are equipped with motors of

1-1/2 HP or less have a metal shipping plate attached between the motor and the blower

housing. The shipping plate must be removed and the plate and screws discarded. On

units factory equipped with an optional belt guard, the belt guard must be removed to

reach the shipping plate.

The concentric adapter assembly in the venting/combustion air kit (Option

CC2 or CC6) is required on all separated combustion models. Be sure that the

concentric adapter carton is at the installation site. (See parts lists in Para-

graph 9.)

Options

Some gas control options have parts either shipped loose

with the heater or shipped separately. If your unit is

equipped with any of the gas control options in the table,

be sure these parts are available at the job site.

Before beginning installation, be sure that all other

shipped-separate options ordered are available at the

site, also. Shipped-separate options could include a

shutoff valve, a condensate drain kit, a thermostat, a

remote console, a disconnect switch, or high tempera-

ture vent sealing tape.

Control Side Side Opposite Controls To Combustibles To Non-Combustibles

6"

(152mm)

Bottom

Sides

Top

6" (152mm) plus

width of unit

6" (152mm)

6" (152mm)

0" (0mm)

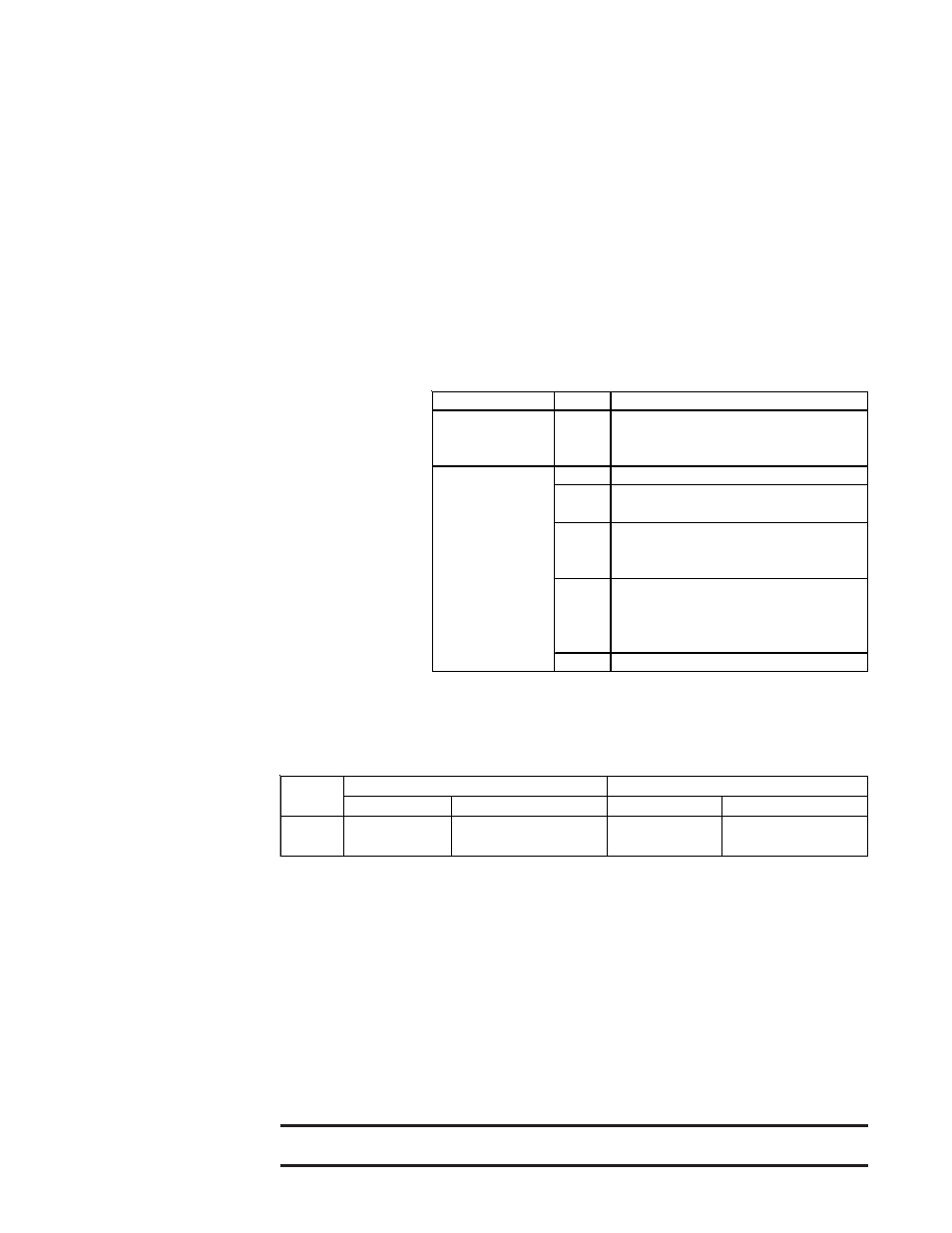

5. Clearances

and Location

For safety and convenience, provide clearances as shown in the following table. Clearance to

combustibles is defined as the minimum distance from the heater to a surface or object that is

necessary to ensure that a surface temperature of 90°F above the surrounding ambient tempera-

ture is not exceeded. Minimum clearances are also listed on the heater rating plate.

Minimum

Clearances

- inches (mm)

Application

Option Shipped Separate Components

Heating -- Gas

Control Option

AG7

Thermostat, P/N 48033

AG3

Control Switch, P/N 29054

Remote Temperature Selector, P/N 48042

Control Switch, P/N 29054

Remote Temperature Selector, P/N 115848

Stage Adder Module, P/N 115849

Control Switch, P/N 29054

Remote Temperature Selector, P/N 115848

Stage Adder Module, P/N 115849

Remote Display Module, P/N 115852

Control Switch, P/N 29054

AG39

Remote Temperature Selector, P/N 174849

Makeup Air -- Gas

Control Options

AG9

AG15

AG16