Sizing gas supply lines – Reznor SCE Unit Installation Manual User Manual

Page 19

Form RZ-NA I-SCE, Mfg #207697 Rev 7,

Page 19

Sizing Gas Supply Lines

Measuring manifold gas pressure cannot be done until the heater is in operation. It is

included in the steps of the "Check-Test-Start" procedure in Paragraph 25. The following

warnings and instructions apply.

For Natural Gas: When the heater leaves the factory, the combination valve is set so that the

outlet gas pressure of a single-stage valve or high fire of a two-stage valve is regulated to

3.5" w.c. Low fire on a two-stage valve is set to 1.8" w.c. Inlet supply pressure to the valve

must be a minimum of 5" w.c. or as noted on the rating plate and a maximum of 14" w.c. NOTE:

Always check the rating plate for minimum gas supply pressure. Minimum supply pressure

requirements vary based on size of burner and the gas control option. Most units require a

minimum of 5" w.c. of natural gas as stated above, but Sizes 350 and 400 with electronic

modulation require a minimum of 6" w.c. natural gas supply pressure. Sizes 300 and 350 with

mechanical modulation require 7" w.c.

For Propane Gas: When the heater leaves the factory, the combination valve is set so that

the outlet gas pressure of a single-stage valve or high fire of a two-stage valve is 10" w.c.

Low fire on a two-stage valve is set to 5" w.c. Inlet pressure to the valve must be a minimum

of 11" w.c. and a maximum of 14" w.c.

Before attempting to measure or adjust manifold gas pressure, the inlet (supply) pressure

must be within the specified range for the gas being used both when the heater is in opera-

tion and on standby. Incorrect inlet pressure could cause excessive manifold gas pressure

immediately or at some future time.

Instructions to Check Valve Outlet (Manifold) Pressure:

1) With the manual valve (on the combination valve) positioned to prevent flow to the main

burners, connect a manometer to the 1/8" pipe outlet pressure tap in the valve. NOTE: A

manometer (fluid-filled gauge) is recommended rather than a spring type gauge due to the

difficulty of maintaining calibration of a spring type gauge.

2) Open the valve and operate the heater. Measure the gas pressure to the manifold. To

measure the low stage pressure on units equipped with a two-stage valve, disconnect the

wire from the "HI" terminal on the valve. (Be sure to reconnect the wire.)

Normally adjustments should not be necessary to the factory preset regulator. If adjustment

is necessary, set pressure to correct settings by turning the regulator screw IN (clockwise) to

increase pressure. Turn regulator screw OUT (counterclockwise) to decrease pressure. Con-

sult the valve manufacturer's literature provided with the furnace for more detailed informa-

tion.

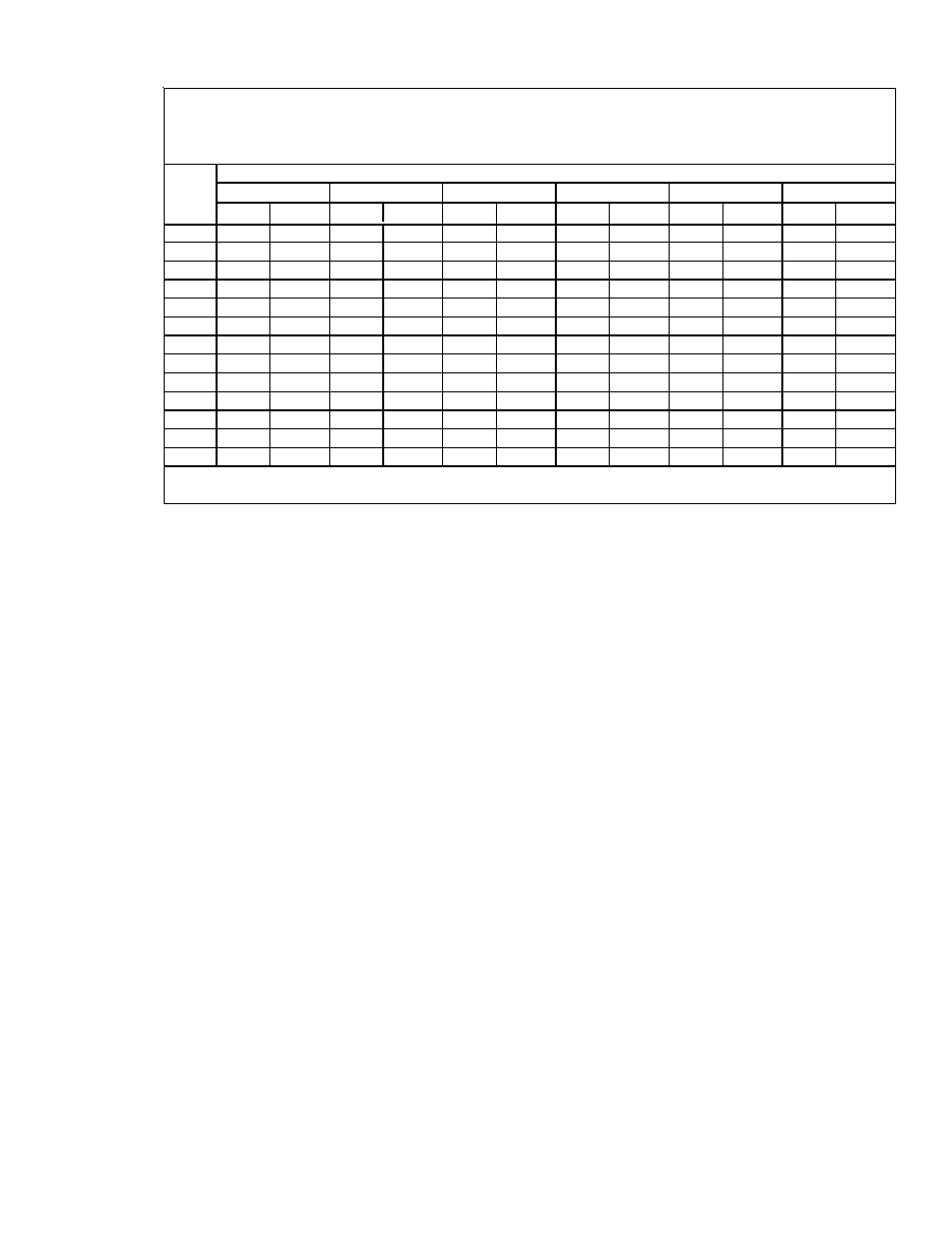

Manifold or Orifice

(Valve Outlet) Pressure

Settings

Capacity of Piping

Cubic Feet per Hour based on 0.3" w.c. Pressure Drop

Specific Gravity for Natural Gas -- 0.6 (Natural Gas -- 1000 BTU/Cubic Ft)

Specific Gravity for Propane Gas -- 1.6 (Propane Gas -- 2550 BTU/Cubic Ft)

Length

Diameter of Pipe

of

1/2"

3/4"

1"

1-1/4"

1-1/2"

2"

Pipe Natural Propan Natural Propan Natural Propan Natural Propan Natural Propan Natural Propan

20'

92

56

190

116

350

214

730

445

1100

671

2100

1281

30'

73

45

152

93

285

174

590

360

890

543

1650

1007

40'

63

38

130

79

245

149

500

305

760

464

1450

885

50'

56

34

115

70

215

131

440

268

670

409

1270

775

60'

50

31

105

64

195

119

400

244

610

372

1105

674

70'

46

28

96

59

180

110

370

226

560

342

1050

641

80'

43

26

90

55

170

104

350

214

530

323

990

604

90'

40

24

84

51

160

98

320

195

490

299

930

567

100'

38

23

79

48

150

92

305

186

460

281

870

531

125'

34

21

72

44

130

79

275

168

410

250

780

476

150'

31

19

64

39

120

73

250

153

380

232

710

433

175'

28

17

59

36

110

67

225

137

350

214

650

397

200'

26

16

55

34

100

61

210

128

320

195

610

372

Note: When sizing supply lines, consider possibilities of future expansion and increased requirements.

Refer to National Fuel Gas Code for additional information on line sizing.