Gas piping and pressures – Reznor SCE Unit Installation Manual User Manual

Page 18

Form RZ-NA I-SCE, Page 18

10. Gas Piping and

Pressures

Gas Connection (Standard Unit)

Model Size

125-250

300-400

Natural Gas

1/2"

3/4"

Propane Gas

1/2"

1/2"

NOTE: The above are gas connection sizes; not supply line sizes.

After all connections are made, disconnect the pilot supply at the control valve and bleed the

system of all air. Reconnect the pilot line and leak test all connections by brushing on a soap

solution.

WARNING

This appliance is equipped for a maximum gas supply pressure of 1/2 psi, 3.5 kPa, or 14 inches

water column. NOTE: Supply pressures higher than 1/2 psi require installation of an addi-

tional service regulator external to the unit.

Pressure Testing Supply Piping

Test Pressure Above 1/2 PSI: Disconnect the heater and manual valve from the gas supply

which is to be pressure tested. Cap or plug the supply line.

Test Pressure Below 1/2 PSI: Before testing, close the manual valve on the heater.

WARNING: Manifold gas pressure must never exceed 3.5" w.c. for

natural gas or 10" w.c. for propane gas.

All piping must be in accordance with requirements outlined in the National Fuel Gas Code

ANSI/Z223.1 (latest edition) or CSA B149.1 and B149.2 (See Paragraph 1.) Gas supply piping

installation should conform with good practice and with local codes.

These separated-combustion units for natural gas are orificed for gas having a heating value

of 1000 (±50) BTUH per cubic ft. If the gas at the installation does not meet this specification,

consult the factory for proper orificing.

Seal the opening for the gas supply pipe with the grommet provided.

Pipe joint compounds (pipe dope) shall be resistant to the action of liquefied petroleum gas

or any other chemical constituents of the gas being supplied.

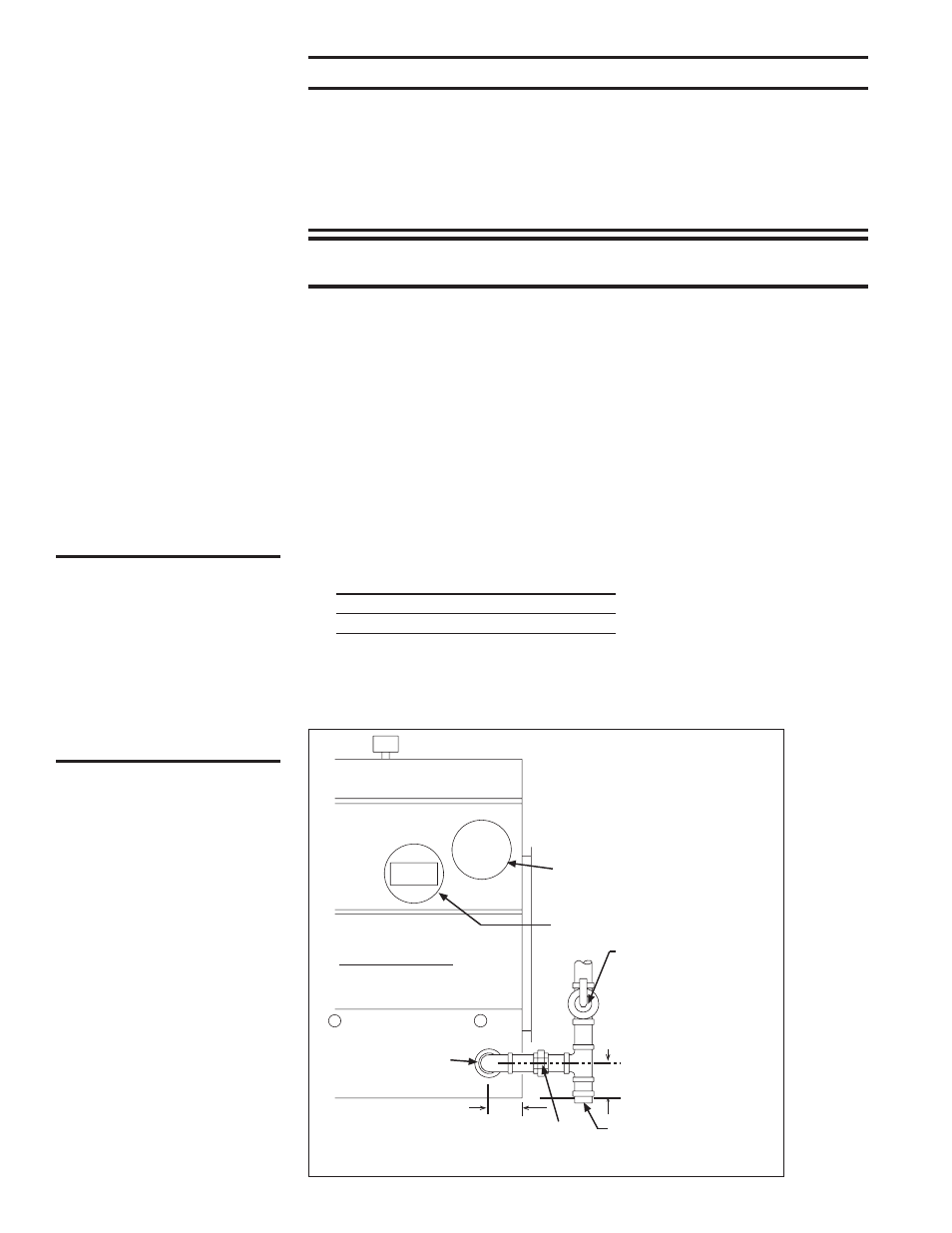

Install a ground joint union and manual shutoff valve upstream of the unit control system.

The 1/8" plugged tapping in the shutoff valve provides connection for supply line pressure

test gauge. The National Fuel Gas Code requires the installation of a trap with a minimum 3"

drip leg. Local codes may require a longer drip leg, typically 6" (See FIGURE 19.).

WARNING: All

components of a gas

supply system must be

leak tested prior to placing

the equipment in service.

NEVER TEST FOR

LEAKS WITH AN OPEN

FLAME. See Hazard

Levels, page 2.

1-1/2

(38)

6 I.D. Combustion

Air Inlet Collar

6O.D. Vent Connection

A manual shutoff

valve with 1/8 NPT

plugged tap, accessible

for test gauge connec-

tion, must be installed

immediately upstream

of the gas supply

connection.

Control Side View

Seal with Grommet

2-3/4

(70)

Ground

Joint

Union

Drip Leg

FIGURE 19 - Gas

Connection