Combustion air proving switch, Fan control, Limit control – Reznor SCE Unit Installation Manual User Manual

Page 23: Motor loads and amps

Form RZ-NA I-SCE, Mfg #207697 Rev 7,

Page 23

13. Combustion Air

Proving Switch

The combustion air proving switch ensures that proper combustion airflow is available. The

switch is a single-pole, double-throw switch, which senses pressure caused by the flow of

combustion air from the venter. The switch is designed to close when a decreasing pressure

is sensed in the outlet duct of the gas collection box.

On startup when the furnace is cold, the sensing pressure is at the most negative level, and

as the furnace and the flue system warm-up, the sensing pressure becomes less negative.

After the system has reached equilibrium (approximately 20 minutes), the sensing pressure

levels off. If a restriction or excessive flue length or turns cause the sensing pressure to

become less than the switch setpoint, the pressure switch will function to shut off the main

burners. The main burners will remain off until the system has cooled and/or the flue system

resistance is reduced. The table below gives approximate water column negative pressure

readings and switch setpoints for sea level operating conditions.

Startup Cold Equilibrium

Factory Setpoint

-1.0" w.c.

-.70" w.c.

-.58 +or- .05" w.c.

NOTE: These settings apply to furnaces that are not equipped with air and gas modulation

Option AG39 or AG40. For pressure switch settings for units equipped with Option AG39 or

AG40, see Paragraph 21.

DANGER: Safe operation requires proper venting flow. Never bypass

the combustion air proving switch or attempt to operate the unit without

the venter running and proper flow in the vent system. Hazardous

condition could result. See Hazard Levels, page 2.

14. Fan Control

1. A fan control provides for the following control of the blower.

(a) After the gas valve opens, there is a time delay of blower operation to prevent the

discharge of cold air.

(b) Blower operation continues after the thermostat is satisfied as determined by the

fan time delay.

2. To be sure that the blower can continue to operate, the power supply to the furnace

MUST NOT be interrupted except when servicing the unit.

3. If the customer wants the furnace off at night, the gas valve circuit SHOULD BE

OPENED by a single pole switch wired in series with the thermostat. Some thermostats

are provided with this feature. Multiple units controlled from a single thermostat are

shut off in the same manner. For proper operation, be sure the fan control wiring is

observed.

15. Limit Control

All models are equipped with an automatic, non-adjustable reset limit control that acts to

interrupt the electric supply to the redundant main operating valve in case of motor failure or

lack of airflow due to restrictions at the inlet or outlet.

16. Motor Loads and

Amps

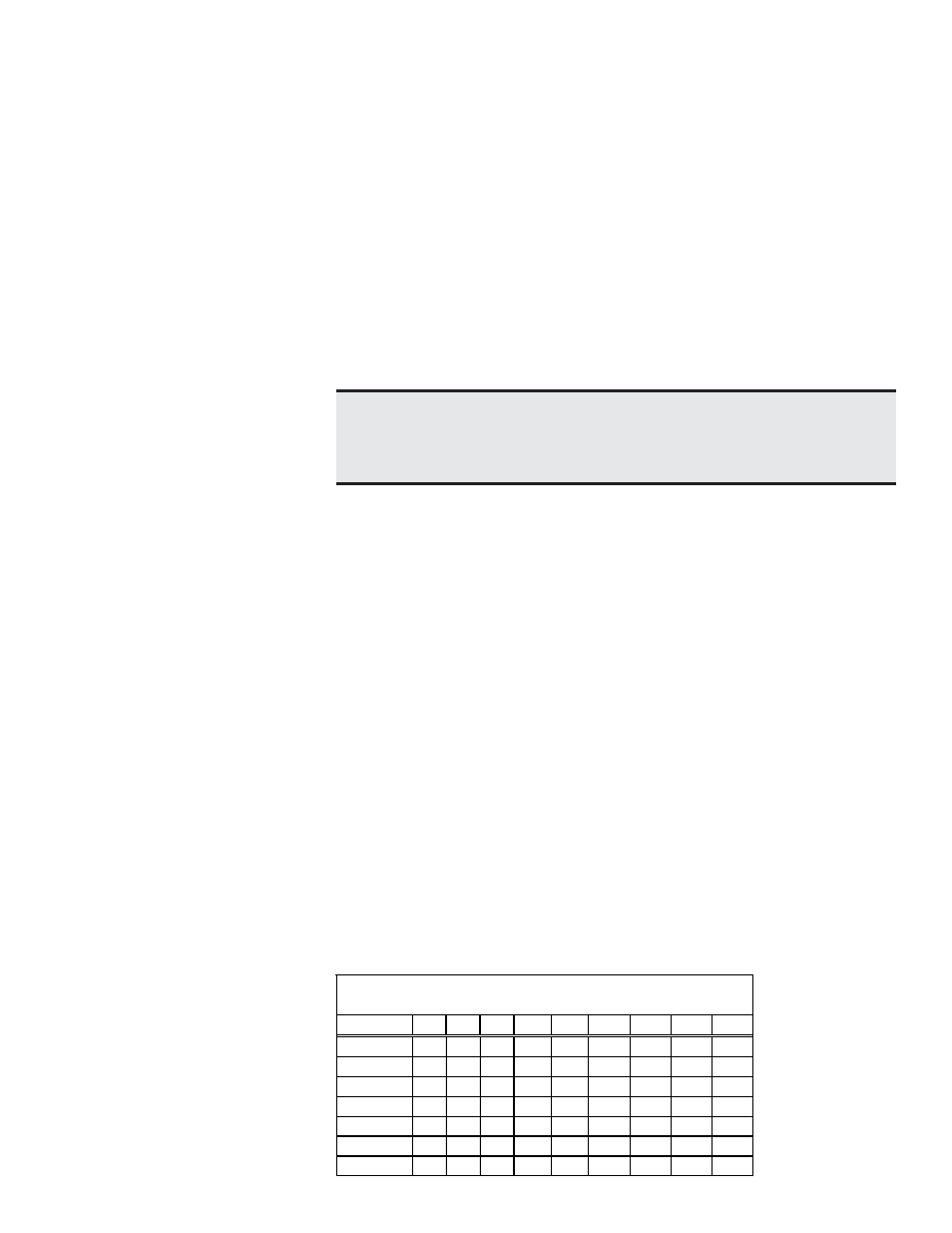

Full Load Amps - Blower Motors (Open)

(Single Speed- Average Values)

HP

1/4 1/3 1/2 3/4

1

1-1/2

2

3

5

115V 1PH 4.6 5.6 8.8 11.0 13.0 18.2 20.4 24.8 N/A

208V 1PH 2.5 3.1 5.1 6.1 7.2 10.1 11.3 13.7 28.0

230V 1PH 2.3 2.8 4.4 5.5 6.5

9.1 10.2 12.4 26.0

208V 3PH 1.7 1.8 2.2 2.9 3.6

5.8

7.3

9.3 14.6

230V 3PH 1.5 1.6 2.0 2.6 3.2

5.2

6.6

8.4 13.2

460V 3PH

.75 .80

1.0 1.3 1.6

2.6

3.3

4.2

6.6

575V 3PH N/A N/A N/A N/A 1.3

2.1

2.6

3.4

5.3

Use an ammeter to check blower motor amps. The chart on the right lists full load amps of

open-type blower motors by HP and voltage . Amps may be adjusted downward by reducing

blower RPM or by increasing duct system static pressure.

This chart can be used for sizing line wiring but should not be interpreted as the exact motor

amps. See the motor rating plate for exact motor specifications. Do not exceed amp rating on

the motor nameplate.

Venter motor amps for a 115 volt or 575 volt unit are 1.5 amps; venter motor amps for a 208,

230, or 460 volt unit are .8 amps.

Service NOTE: To replace the fan

control on units manufactured prior

to 11/04, a replacement kit is

required. Order P/N 209184.