Service and maintenance, Operating gas valve – Reznor SCE Unit Installation Manual User Manual

Page 33

Form RZ-NA I-SCE, Mfg #207697 Rev 7,

Page 33

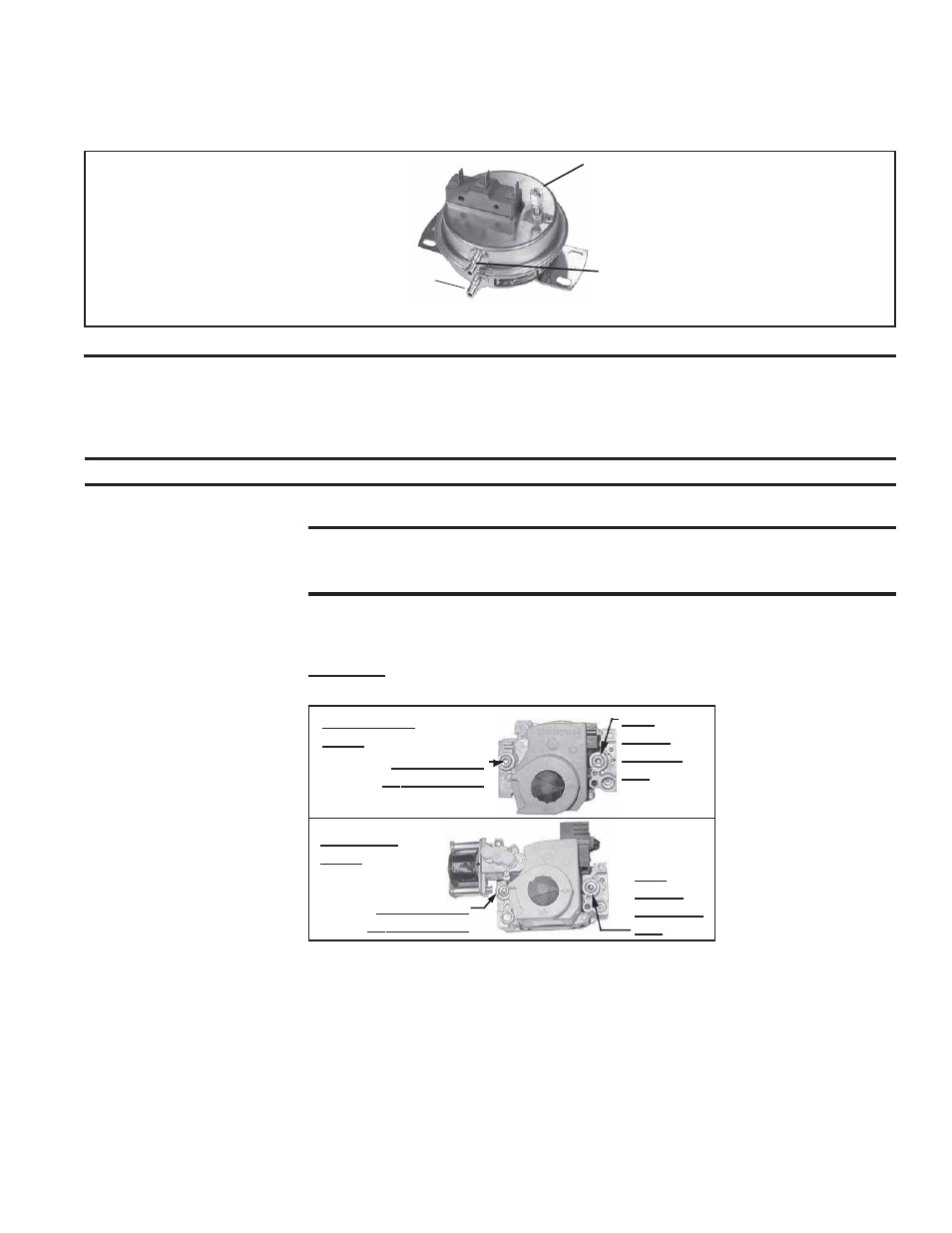

FIGURE 33 - Dirty Filter

Switch

Set screw (on front of switch)

must be manually adjusted after

the system is in operation.

Negative pressure connection is toward the

"back or bottom" of the switch (senses

blower side of filters)

Positive pressure connection is

toward the "front or top" of the

switch (senses air inlet side of filters)

SERVICE AND

MAINTENANCE

This unit will operate with a minimum of maintenance. To ensure long life and satisfactory perfor-

mance, a furnace that is operating under normal conditions should be inspected every four

months. If the furnace is operating in an area where an unusual amount of dust or soot or other

impurities are present in the air, more frequent inspection is recommended.

2) With the manual valve turned off to prevent flow to the gas valve, connect a manometer to the 1/8” inlet pressure tap in the

valve. NOTE: A manometer (fluid-filled gauge) with an inches water column scale is recommended.

3) With the field-installed manual valve remaining closed, observe the manometer for two to three minutes for an indication of gas

pressure. No pressure should be indicated on the manometer.

If the manometer indicates a gas pressure , the field-installed manual gas valve must be replaced or repaired before the combi-

nation gas valve can be checked.

4) If the manometer does not indicate gas pressure , slowly open the field-installed manual gas valve. After the manometer's

indicated gas pressure has reached equilibrium, close the manual shutoff valve. Observe the gas pressure. There should be no

loss of gas pressure on the manometer. If the manometer indicates a loss of pressure, replace the combination gas valve before

placing the heater in operation.

NOTE: Operational pressure settings and instructions for checking pressure settings are in Paragraph 10.

28. Operating Gas

Valve

Instructions for

Setting Dirty Filter

Switch

With clean filters in place, blower doors closed, and blower in operation, decrease the pressure

setting by adjusting the set screw on the switch clockwise until the filter light is energized or the

screw is bottomed out. At that point, adjust the set screw three full turns counterclockwise or

until the screw is top-ended. At that setpoint the filter light will be activated at approximately 50%

filter blockage.

WARNING: If you turn off the power supply, turn off the gas. See Hazard Levels, page 2.

NOTE: Use only factory-authorized replacement parts.

WARNING: The operating valve is the prime safety shutoff. All gas supply

lines must be free of dirt or scale before connecting to the unit to ensure

positive closure. See Hazard Levels, page 2.

Remove external dirt accumulation and check wiring connections.

The combination gas valve must be checked annually to ensure that the valve is shutting off gas

flow completely.

Instructions :

1) Locate the 1/8” FPT INLET pressure tap on the combination valve (See FIGURE 34).

FIGURE 34 - Connect

manometer to inlet

pressure tap to check gas

flow shutoff.

Single-Stage

Valve

Two-Stage

Valve

1/8" INLET

Pr essure Tap

1/8”

Outlet

Pressure

Tap

1/8" INLET

Pr essure Tap

1/8”

Outlet

Pressure

Tap