Reznor SCE Unit Installation Manual User Manual

Page 6

Form RZ-NA I-SCE, Page 6

7. Optional

Condensation

Drain for Duct

Furnaces

8. Duct Connections

Model SCE furnaces are

for installation upstream or downstream from a cooling coil.

When installed downstream from a refrigeration system, condensation will form; and there-

fore, adequate provision must be made to dispose of condensate.

Periodic cleaning of the condensate collection and disposal system is required.

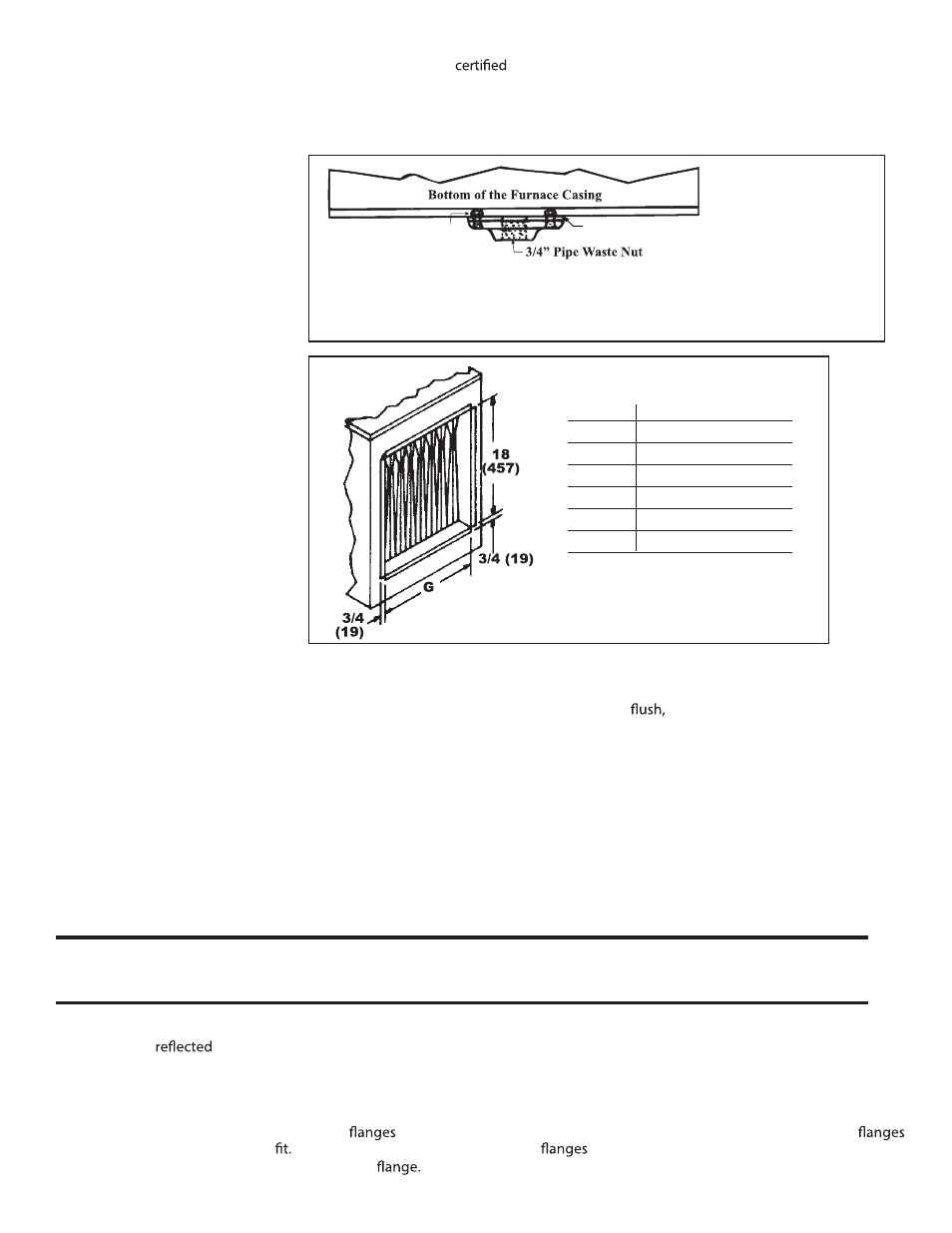

Install drain connection, Option CS1, on the furnace casing as illustrated in FIGURE 5.

Terminate drain outside of the building. Provide a trap to prevent air from entering the

combustion zone. Periodic cleaning of the condensate collection and disposal system is

required. NOTE: Requires a four-inch (102mm) minimum clearance under the furnace if a

90° street elbow is used.

FIGURE 5 - Option CS1,

P/N 31765, Optional

Condensate Drain

Connection

FIGURE 6 - Duct

Connection Dimensions -

inches (mm)

Requirements and Suggestions for Connecting and Installing Ducts

•

Type of Ductwork - The type of duct installation to be used depends in part on the type of construction of the roof (whether

wood joist, steelbar joist, steel truss, pre-cast concrete) and the ceiling (whether hung,

etc.).

•

Ductwork Material - Rectangular duct should be constructed of not lighter than No. 26 U.S. gauge galvanized iron or No. 24 B

& S gauge aluminum.

•

Ductwork Structure - All duct sections 24 inches (610mm) or wider, and over 48 inches (1219mm) in length, should be cross

broken on top and bottom and should have standing seams or angle-iron braces. Joints should be S and drive strip, or locked.

•

Through Masonry Walls - No warm air duct should come in contact with masonry walls. Insulate around all air duct through

masonry walls with not less than 1/2" (1" is recommended) of insulation.

•

Through Unheated Space - Insulate all exposed warm air ducts passing through an unheated space with at least 1/2" (1" is

recommended) of insulation.

•

Duct Supports - Suspend all ducts securely from adjacent buildings members. Do not support ducts from unit duct connections.

•

Duct Sizing - Proper sizing of the supply air ductwork is necessary to ensure a satisfactory heating installation. The recognized

authority for such information is the Air Conditioning Contractors Association, 2800 Shirlington Road, Suite 300, Arlington, VA

22206 (www.acca.org). A manual covering duct sizing in detail may be purchased directly from them.

CAUTION: An external duct system static pressure not within the limits shown on the rating

plate, or improper motor pulley or belt adjustment, may overload the motor. See Hazard Levels,

page 2.

•

Removable Panels - The ducts should have removable access panels on both upstream and downstream sides of the furnace.

These openings must be accessible when the furnace is in service and should be a minimum of 6" x 10" (152mm x 254mm) in size

so smoke or

light may be observed inside the casing to indicate the presence of leaks in the heat exchanger. The

covers for the openings must be attached in such a manner as to prevent leakage. See FIGURE 7A

•

Horizontal Discharge Duct Length - A minimum horizontal duct run of 24" (610mm) is recommended before turns or branches

are made in the duct system to reduce losses at the furnace outlet.

•

Supply Air Duct/Furnace Horizontal Connection - The seal between the furnace and the duct must be mechanical. Duct

connection should be made with "U" type

on the top and bottom of the connecting duct. Slide the duct over the

of the heater giving an airtight Provide "U" type channels for the side

to ensure tight joints. Use sheetmetal screws

to fasten ducts and "U" channels to the furnace

See FIGURE 7B

Size

G

125

15-1/4" (387mm)

150, 175

20-3/4" (527mm)

200, 225

26-1/4" (667mm)

250, 300

34-1/2" (876mm)

350

40" (1016mm)

400

45-1/2" (1156mm)

#10-32 x 1”Lg Machine

Screw & Nut

RTV Sealant

Seal holes in bottom

pan with RTV sealant