Blowers, belts and drives – Reznor SCE Unit Installation Manual User Manual

Page 24

Form RZ-NA I-SCE, Page 24

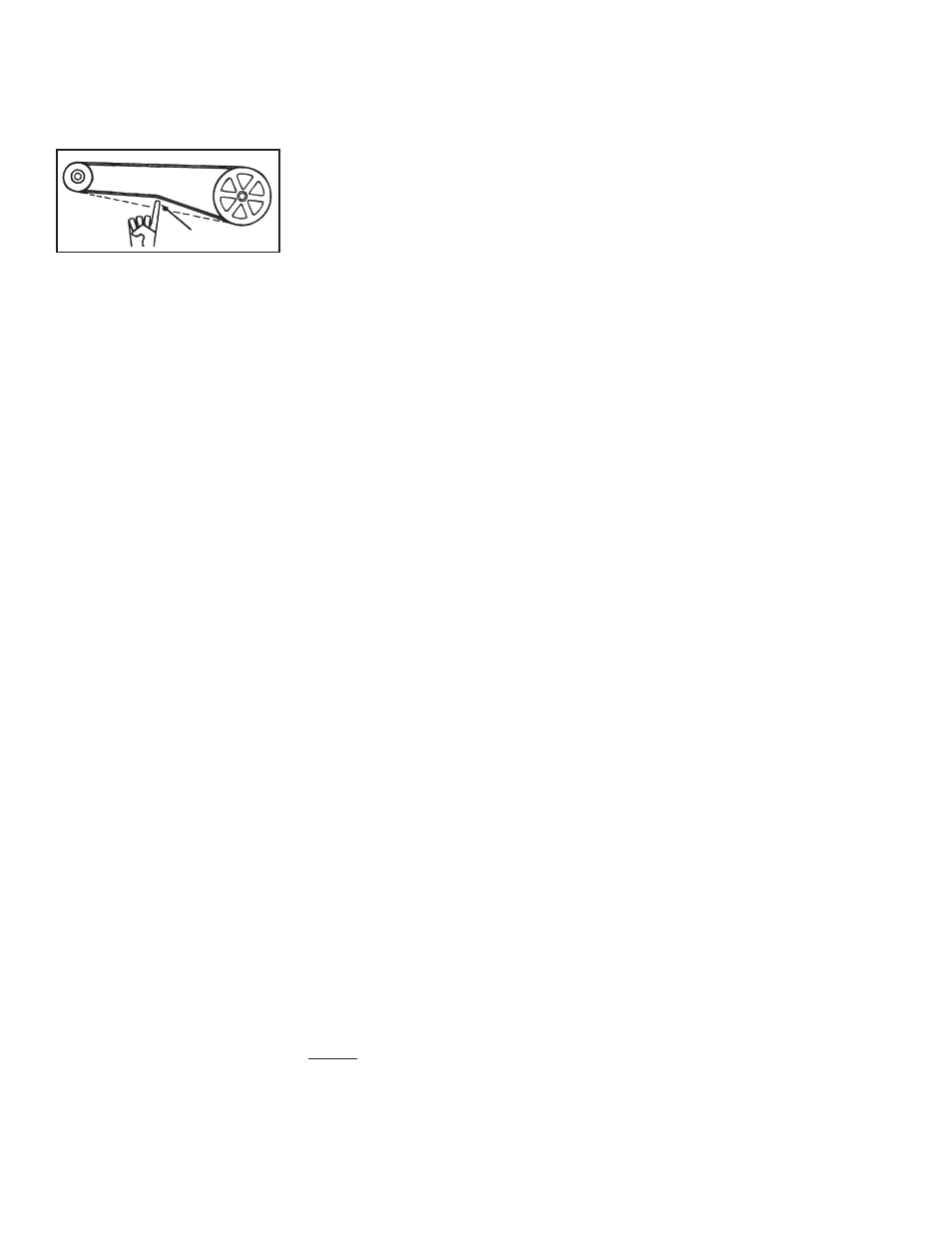

3/4 (19mm)

FIGURE 22 - Check Belt

Tension

17. Blowers, Belts

and Drives

Check belt tension. Proper belt tension is important to the long life of the belt and motor. A

loose belt will cause wear and slippage. Too much tension will cause excessive motor and

blower bearing wear. Adjust the belt tension by turning the adjusting screw on the motor

base until the belt can be depressed 3/4" (19mm). (See FIGURE 22.) After correct tension is

achieved, re-tighten the locknut on the adjustment screw. Be sure that the belt is aligned in

pulleys.

Adjusting Blower Speed

The blower speed may be adjusted to achieve the desired outlet temperature, as long as the

adjustment is within the temperature rise and the static pressure limits shown on the furnace

rating plate. Motors are factory set between maximum and minimum blower speeds.

If the duct resistance is low, the blower may deliver too high an air volume. If the resistance

is very low, the blower may deliver excess air to overload the motor, causing the overload

protector to cycle the motor. Reducing the blower speed will correct these conditions. If

ductwork is added to an installation, it may be necessary to increase the blower speed.

Decreasing blower speed will increase outlet temperature; increasing blower speed will de-

crease outlet temperature.

At final adjustment, amperes should not exceed motor nameplate amp rating. The installa-

tion must be adjusted to obtain a temperature rise within the range specified on the furnace

rating plate.

The belt drive on these units is equipped with an adjustable pulley which permits adjustment

of the blower speed. Follow these instruc-

tions to adjust the blower speed.

1. Turn off the gas and the electric power.

2. Loosen belt tension and remove the belt.

3. Loosen the set screw on the side of the pulley away from the motor.

4. To increase the blower speed, decreasing outlet temperature, turn the

adjustable half of the pulley inward. To decrease the blower speed, increasing

the outlet temperature, turn the adjustable half of the pulley outward. One

turn of the pulley will change the speed 8-10%.

5. Tighten the set screw on the flat portion of the pulley shaft.

6. Replace the belt and adjust the belt tension. Adjust tension by turning the

adjusting screw on the motor base until the belt can be depressed 3/4". (See

FIGURE 22.) Re-tighten the lock nut on the adjusting screw. Be sure that the

belts are aligned in the pulley grooves properly and are not angled from pulley

to pulley.

7. Turn on the gas and electric. Light the heater following the instructions on the

lighting instruction plate.

8. Check the motor amps with an ammeter. The maximum motor amp rating on the

motor nameplate must not be exceeded.

When service is complete, check for proper operation.

Blower Rotation

Each blower housing is marked for proper rotation. Rotation may be changed on single-

phase motors by re-wiring in the motor terminal box. Three-phase motors may be reversed by

interchanging two wires on the 3-phase supply connections.

Optional Variable

Frequency Drive

If the system is equipped with an optional variable frequency drive, the motor will operate on

speeds as determined by the electrical frequency. 60 hertz is maximum speed. Speeds must be

within the temperature rise range of a Model SCE Series 6 heater which is 30-90°F.

Follow the variable frequency controller manufacturer's instructions that are packaged with

the heater (in the owner's envelope) to program the variable frequency drive settings. The

formula for motor speed is N = 120 x f/p where N is speed; f is frequency; and p is number of

poles (3600 RPM motor has 2 poles; an 1800 RPM motor has 4 poles).

Example: 1800 RPM motor on 60Hz; N = 120 x 60/4 = 1800

1800 is synchronous speed; assume 2% slip. Motor will run between 1750

and 1790 RPM at full load depending on design. Run the same motor at

45Hz (120 x 45/4 = 1350). 1350 RPM less 2% slip equals about 1300 RPM.