Caua: ag2-ak5-an2, Dsi control – Reznor CAUA Unit Installation Manual User Manual

Page 37

Form I-CAUA, P/N 164771 R8, Page 37

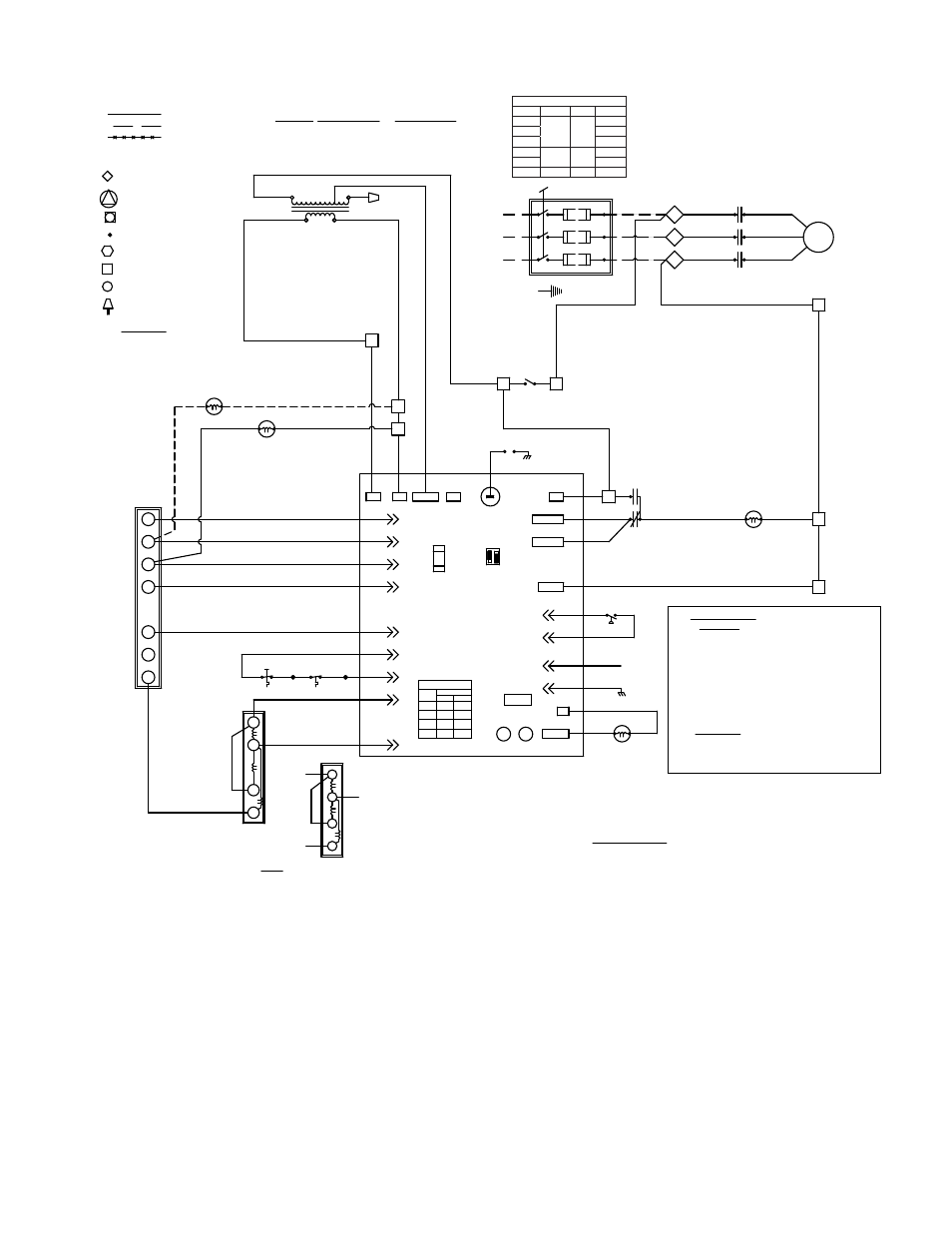

FIGURE 29C - Wiring Diagram with Two-Stage Gas Control and Belt-Driven Blower Motor

VENTER MOTOR (VM1)

LED

DSI CONTROL

SW1

FAN OFF DELAY

TIME

90

120

160

180

OFF

OFF

ON

ON

ON

OFF

OFF

ON

1

2

S W 1

IND

BK OR BL

NEUTRAL

BK OR BR

(SEE NOTE #6)

LED

OK

FLAME

G

Y

NEUTRAL

LIMIT CONTROL

R

R

R

P1-8

P1-3

BK OR BL

BR

P1-2

P1-4

BL

BK

L1

NEUTRAL

L1

SEC

AT

O OR A

TC

3.0 A

MP

TEST

FUSE

FLAME

ROLLOUT SWITCH

ACB HEAT

ACB COOL

W

L1

L2

W

L2

COM

1

O

BR

FLAME

ELECTRODE

FLAME

GROUND

P1-7

P1-9

PRESSURE SWITCH

Y

Y

P1-6

P1-5

W

3

SPARK GAP

SPARK

TRANSFORMER

BL

BK

BR

TRANSFORMER

40 VA

BR

BL

BK

R

BL

DOOR SWITCH

BK

BK

BK

CAUA: AG2-AK5-AN2

WD #280690

R

R

C

NO

SEE NOTES (right) FOR

LED FLASH CODES

(TX1)

(DS1)

3

BK

BK

FAN RELAY

CONTACTS (CR1)

2

4

6

BK

R

W

G

Y

P3-4

P3-3

P3-2

R

G

W

TERMINAL STRIP

THERMOSTAT

C

Y1

Y2

W1

W2

P3-1

Y

P3-5

BR

G

FAN RELAY

COIL (CR1)

Y

8

7

BR

7

R

C

BR

RELAY COIL

CUSTOMER'S COOL

7

FOR THERMOSTAT

CONNECTIONS

SEE PAGE 1

(NOT IN

SEQUENCE)

PIL

O

T

AL

TERNA

TE

W

.R. T

WO

ST

AGE

REDUND

ANT

GAS V

AL

VE

R

3

HIGH S

TG

4

BL

STG

2

LO

W

1

BR

BK

PL

UG PIL

O

T OPENING

R

BL

BK

PL

UG PIL

O

T OPENING

HONE

YWELL T

WO

ST

AGE

REDUND

ANT

GAS V

AL

VE

PIL

O

T

PV

HI

HIGH S

TG

LO

W

STG

C

MV

BR

R

BK

CONTACTOR COIL

MOTOR

W

BK

CONTACTOR

MOTOR

MOTOR

BLOWER

L2

L1

R

R

T2

T1

T3

L3

R

R

R

R

L2

GRD

G

DISCONNECT SWITCH

208/3/60

L2

L3

L1

(SEE NOTES)

BK

Y

24V

208V

R

BK

R

Y

FIELD CONTROL WIRING

150'

250'

350'

75'

125'

175'

#18 GA. WIRE

#16 GA. WIRE

#14 GA. WIRE

TOTAL WIRE

LENGTH

DISTANCE FROM

UNIT TO CONTROL

MIN. RECOMMENDED

WIRE GAUGE

FIELD WIRING

OPTIONAL

FACTORY WIRING

FACTORY WIRING

WHITE - W

PURPLE - PR

BLUE - BL

GREEN - G

YELLOW - Y

ORANGE - O

RED - R

BROWN - BR

BLACK - BK

WIRING CODE

MAIN TERMINAL BLOCK

UNIT TERMINAL STRIP

THERMOSTAT TERMINAL

STRIP

CRIMP TERMINAL

WIRE CONNECTOR

MIXING BOX

AUXILIARY MAIN

THREE PHASE POWER

TERMINAL STRIP

FAST FLASH UNDESIRED FLAME (VALVE OPEN &

NO CALL FOR HEAT)

IN LOCKOUT FROM FAILED IGNITIONS OR

FLAME LOSSES

PRESSURE SWITCH IS CLOSED BEFORE

VENTER IS ENERGIZED

PRESSURE SWITCH DOES NOT CLOSE WITHIN

30 SECONDS OF VENTER ENERGIZED

WEAK FLAME

INTERNAL CONTROL FAULT OR NO POWER

YELLOW LED

FLAME SENSED

LIMIT SWITCH OPEN

NORMAL OPERATION NO CALL FOR HEAT

NORMAL OPERATION CALL FOR HEAT

LED FLASH CODES

GREEN LED

STEADY ON

FAST FLASH

1 FLASH

2 FLASH

SLOW FLASH

3 FLASH

STEADY OFF

4 FLASH

STEADY ON

OPERATING SEQUENCE

USE DUAL ELEMENTS TIME DELAY FUSES AND SIZE ACCORDING TO 1.25

7. WHEN PROVIDING OR REPLACING FUSES IN THE FUSIBLE DISCONNECT SWITCH

6. VENTER MOTOR ON 350-400 UNITS HAS BROWN AND BLUE WIRES.

VOLTAGE DROPS BEYOND 5% OF SUPPLY LINE VOLTAGE.

5. LINE AND FAN MOTOR BRANCH WIRE SIZES SHOULD BE OF A SIZE TO PREVENT

HAVING A TEMPERATURE RATING OF AT LEAST 105° C. EXCEPT FOR SENSOR

APPLIANCE MUST BE REPLACED, IT MUST BE REPLACED WITH WIRING MATERIAL

3. CAUTION: IF ANY OF THE ORIGINAL WIRING AS SUPPLIED WITH THE

1. THE FOLLOWING CONTROLS ARE SUPPLIED AS OPTIONAL EQUIPMENT:

TIMES THE MAXIMUM TOTAL INPUT AMPS.

4. USE #18 GA. WIRE FOR CONTROL WIRING ON THE UNIT.

LEAD WIRE WHICH MUST BE 150° C.

2. DOTTED WIRING INSTALLED BY OTHERS.

NOTES

8. DISCONNECT SWITCH IS FIELD FURNISHED OR AVAILABLE FROM FACTORY AS AN OPTION.

THERMOSTAT

- WHEN BLOWER DOOR IS OPENED, THE UNIT IS SHUTDOWN.

1. SET THERMOSTAT SYSTEM SWITCH AT "OFF" POSITION,

2. TURN ON MANUAL GAS VALVE.

3. TURN ON POWER TO UNIT.

- THERMOSTAT CALLS FOR LOW HEAT, ENERGIZING THE VENTER MOTOR.

- VENTER PRESSURE SWITCH CLOSES, FIRING UNIT AT LOW RATE.

- BURNER FLAME IS SENSED, AND IN 30 SECONDS THE BLOWER

MOTOR IS ENERGIZED.

- IF THE FLAME IS EXTINGUISHED DURING MAIN BURNER OPERATION,

THE INTEGRATED CONTROL SYSTEM CLOSES THE MAIN VALVE AND

MUST BE RESET BY INTERRUPTING POWER TO THE CONTROL CIRCUIT

(SEE LIGHTING INSTRUCTIONS).

4. SET THERMOSTAT SYSTEM SWITCH AT "AUTO" POSITION,

5. SET THERMOSTAT SYSTEM SWITCH AT "OFF" POSITION FOR SHUTDOWN.

- ON CALL FOR COOLING THE BLOWER IS ENERGIZED AND CUSTOMER'S

FAN SWITCH AT "AUTO" POSITION.

FAN SWITCH AT "AUTO" POSITION.

COOLING CIRCUIT IS ENERGIZED.

- ON CALL FOR HIGH HEAT THE UNIT FIRES AT FULL RATE.

Line and Motor Wiring Size

HP

Voltage

Phase Wire Ga

1/4-2

208-230

1

14

3

10

5

8

1/4-3

208-230

3

14

5

12

1/4-5

460-575

3

14