0 mechanical (cont'd) – Reznor CAUA Unit Installation Manual User Manual

Page 32

Form I-CAUA, P/N 164771 R8, Page 32

6.0 Mechanical

(cont'd)

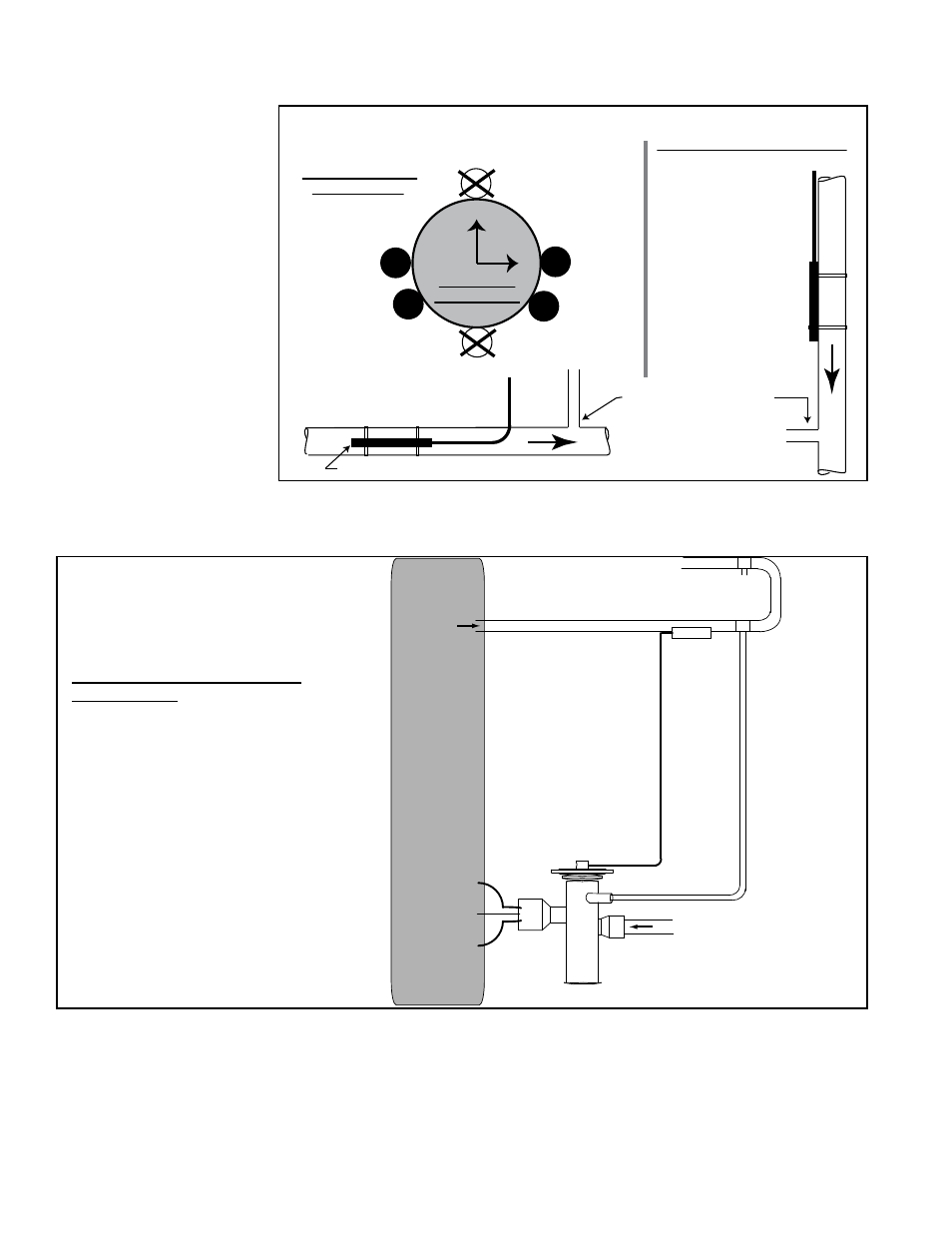

Bulb at

3 o’clock

Bulb at

4 o’clock

Bulb at

8 o’clock

Bulb at

9 o’clock

12

3

6

9

Position bulb flat against the surface of the suction line tubing. Secure bulb

tightly and insulate.

Suction Line

Cross Section

Suction Line

Thermostatic Expansion Valve Bulb

Suction Line

Thermostatic

Expansion

Valve Bulb

(Capillary tube should

be out the top.)

Horizontal Section

of Suction Line

(preferred location)

Vertical Section of Suction Line

(descending flow only)

Capillary

tubing

from TEV

Capillary tubing from TEV

Connect field-supplied

equalizer tubing from the TEV

(FIGURE 25B) into the

suction line a short

distance downstream

of the bulb.

6.6 Cased Cooling Coil, Model ACUA, ACUB, or ACUC or

Option C (cont'd)

FIGURE 25A -

Suction Line

showing Orientation

and Location of

the Thermostatic

Expansion Valve

Bulb and the Equalizer

Tubing

(applies to each circuit)

Thermostatic Expansion Valve

Equalizer Line - To ensure that

the correct pressure is signaled

to the valve, an external equalizer

line must be connected into the

suction line downstream of the

thermostatic expansion valve

bulb. (See location indicated in

FIGURES 25A and 25B.)

Connect the other end of the

equalizer tubing to the 1/4" ODF

stem on the thermostatic expansion

valve as shown in

FIGURE 25B.

FIGURE 25B - Thermostatic

Expansion Valve with External

Equalizer Line Fitting

(required for each circuit)

External equalizer

line requires field-

supplied tubing

from the 1/4” ODF

fitting on the valve

and connected

into the suction

line preferably at

location “X” down-

stream of the

TEV bulb. If “X” is

not possible,

location “Y” is

acceptable as long

as pressure is

essentially the

same as at “X”.

Thermostatic

Expansion

Valve (TEV)

Evaporator Coil in Model

ACU or Option C

Cased Cooling Coil

TEV Bulb

Suction Line

X

Y

Cased Cooling Coil

Drain Line

The cased coil has a 3/4" FPT drain connection. Install a trap (see below) and pitch

the drain line downward at least 1/2" (13mm) for every 10 feet (3M) of horizontal run.

Drain lines must not interfere with access panels. An obstruction in the drain or a poorly

designed drain can cause an over flow. Overflow could result in unit or building dam-

age.

Connect the burner condensate tubing into the cooling coil drain line and continue into

a sanitary drain system.

In addition, an external equalizer line must be installed from the stem on the valve to

a location on the suction line that is downstream of the bulb. Follow the instructions in

FIGURE 25B to install the field-provided tubing.