Great Planes PT-40 MkII Kit - GPMA0118 User Manual

Page 7

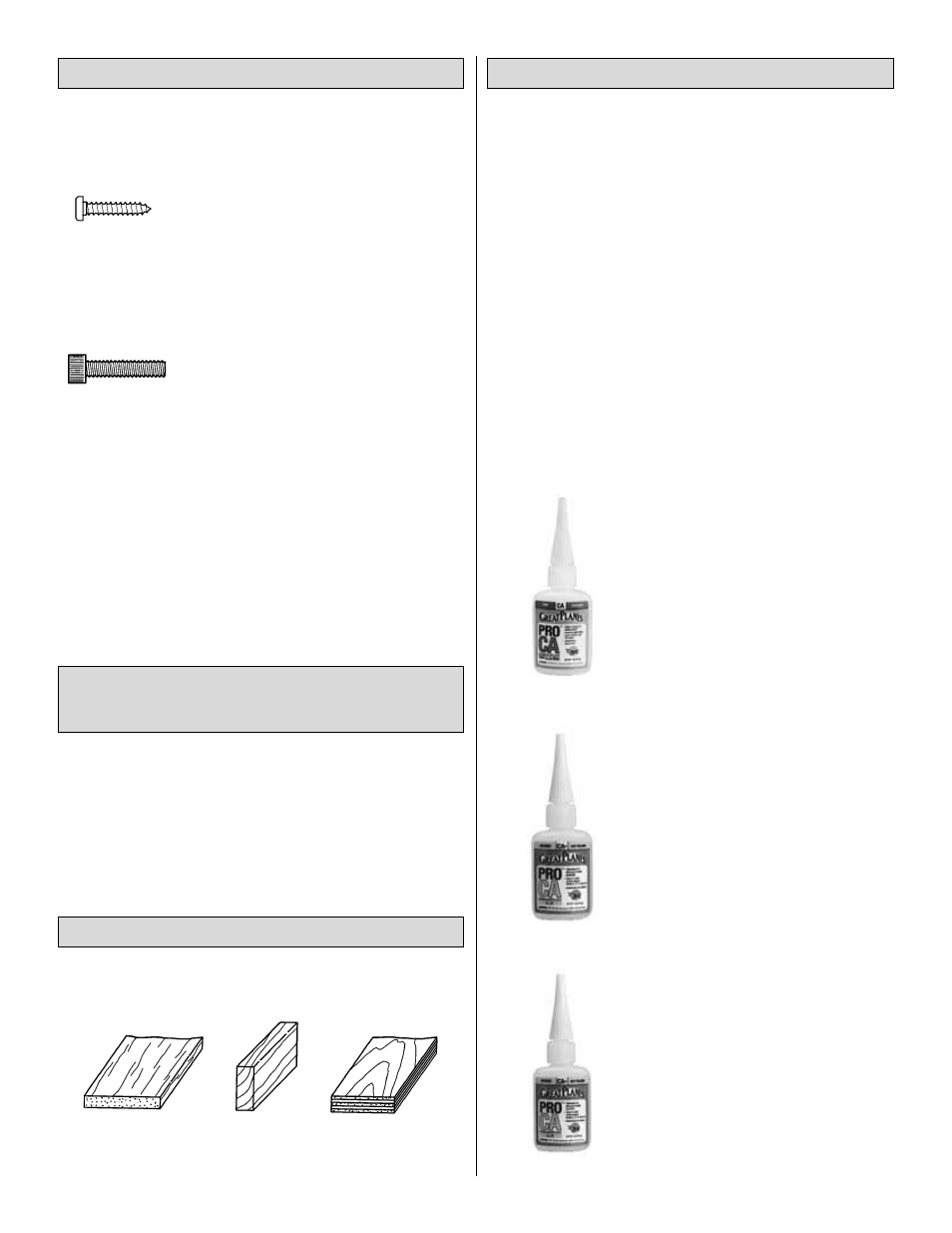

• There are two types of screws used in this kit:

Sheet metal screws are designated by a number and

a length.

For example #4 x 5/8".

Machine screws are designated by a number (threads per

inch) and a length.

For example 4-40 x 3/4".

• When you see the term “test fit” in the instructions, it

means you should first position the part on the assembly

without using any glue, then slightly modify or “custom fit”

the part as necessary for the best fit.

• Whenever just “epoxy” is specified you may use

either

30-minute epoxy or 6-minute epoxy. When 30-minute epoxy

is specified it is highly recommended that you use only

30-minute epoxy because you will need either the working

time and/or the additional strength.

Fuse = Fuselage

Stab = Horizontal stabilizer

Fin = Vertical fin

LE = Leading edge (front)

TE = Trailing edge (rear)

LG = Landing gear

Ply = Plywood

" = Inches

Cyanoacrylate or CA glue has changed the way models

are built more than any other advance in modeling

technology. In the good ol' days, model cement like

Ambroid, Duco, Comet and Sigment were the glues of

choice. They all had a strong odor that could cause

dizziness, dried slowly (compared to CA) and became

brittle with age. CA, on the other hand, is stronger, works

almost instantly and is bottled in three different viscosities

(thicknesses). CA is used for most glue joints, except where

epoxy is specified. CA does emit rather strong fumes (some

say it's like tear gas) as it cures, so rule number one is to

work in a well ventilated area.

All CA glues work best if the joints are smooth and the

parts fit well.

Thin CA is also known as plain CA.

This is the instant variety, used for

most initial assembly and tack gluing.

Thin CA is usually “wicked” into a

tightly fitting joint by putting a few

drops on the seam, then holding the

par ts together while the CA

penetrates and bonds the par ts.

When gluing plywood or hardwood, a

mist of accelerator (see page 8) will

help the CA work a little better.

CA+ is also known as medium or

gap filling CA. CA+ is used for

surface gluing, filling small gaps

between poorly matched parts and

for general purpose applications. It

cures slower than thin CA, allowing

you to apply a bead to two or three

parts before assembly. Also, because

it cures slower than thin CA, it

penetrates the wood for a stronger

bond. Curing time without accelerator

is 20 - 30 seconds.

CA- or thick CA is used when extra

positioning time is needed. CA- is a

great gap filler and is also used to

make fillets when a little extra

strength is required. Curing time is

about 1 - 2 minutes.

The What and How of Adhesives

Types of Wood

Common Abbreviations Used in this

Manual and on the Plans

Building Notes

7

Balsa

Basswood

Plywood

#4 x 5/8" Sheet Metal Screw

4-40 x 3/4" Socket Head Cap Screw