Expert tip – Great Planes PT-40 MkII Kit - GPMA0118 User Manual

Page 22

Note: You will need your engine for the following steps.

From here on it is a good idea to plug the holes in your

engine so balsa dust cannot get in. Stuff a piece of paper

towel into the exhaust and carburetor venturi to seal

them off.

❏

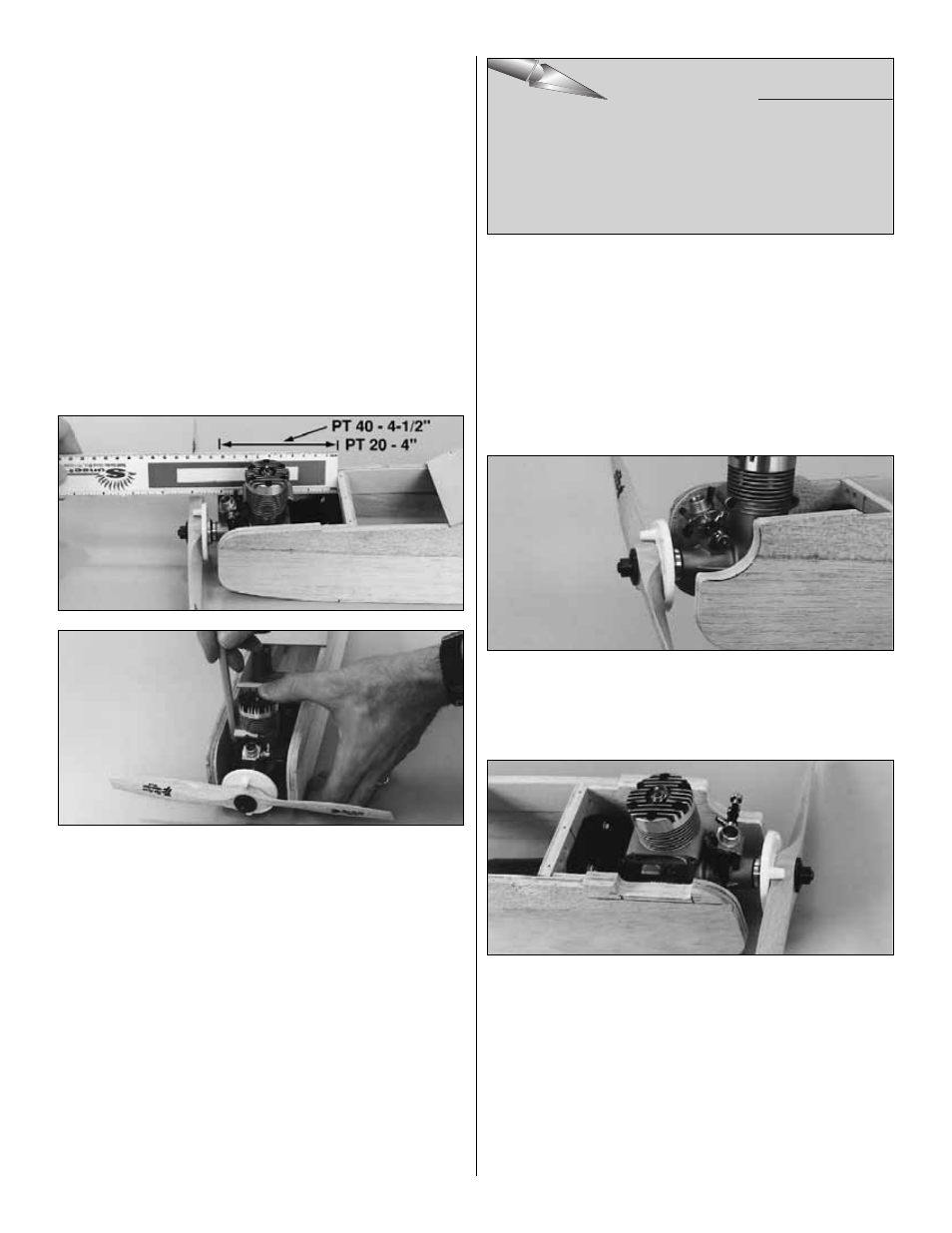

4. Remove the needle valve from your engine. Position

the engine on the engine mount and adjust the engine

mount halves until the engine mounting lugs will sit flat on

the rails. Position the mount so the firewall centerline is

centered between the “tick” marks on the mount. Tighten

the screws to hold the mount firmly in position against

the firewall.

❏

5. Mount the spinner back plate on your engine. If you’re

building the PT-40 position the engine so that the spinner

backplate is 4-1/2" (115mm) from the firewall. If you’re

building the PT-20, position the engine so that the spinner

pack plate is 4" (102mm) from the firewall. Carefully mark

the engine mounting holes on the rails with a sharpened

piece of wire or a pencil. Note: If installing a 4-stroke

engine, the engine may be forward of the recommended

position to allow for the choke mechanism. This is

acceptable and will not cause a balance problem.

❏

6. Remove the engine and engine mount from the fuse.

Use a center punch or sharpened nail to "dimple" the marks

on the rails, then drill a 3/32" hole through the rails at each

punch mark. If you have access to a drill press, this is the

best tool for the job. However, if you are using a hand-held

electric drill, try to keep the bit perpendicular to the rails.

❏

7. Install a threaded ball stud in the bottom hole of the

carburetor arm of your engine and secure it with a 0-80 nut

and a drop of epoxy or thread locking compound. Fasten

the engine to the mount with four #4 x 5/8" screws

included in this kit (or your 4-40 screws). Hint: Add a drop

of household oil to the #4 sheet metal screws to make them

easier to screw into the mount.

❏

8. Carefully and neatly cut away some of the fuselage

side so you can reach the needle valve. A Dremel tool with

a sanding drum works well for this.

❏

9. Remove some of the fuselage side to clear the

muffler. There should be approximately 1/8" clearance

between the muffler and the fuselage.

❏

10. From one of the leftover pieces of outer pushrod

tube (you saved from the elevator and rudder guide tubes)

cut a piece for the throttle guide tube. It should extend

1/2" past the firewall and 1/2" aft of F-2. Temporarily install

the throttle guide tube through the holes in the firewall

and F-2.

EXPERT TIP

EXPERT TIP

EXPERT TIP

22

Some modelers prefer to secure the engine to the mount

with machine screws (not supplied) because they are

easier to screw in. For both the PT-20 and 40, 4-40 x 3/4"

screws are recommended. Use a #48 drill bit to drill the

holes, then tap the threads with a 4-40 tap.