Great Planes PT-40 MkII Kit - GPMA0118 User Manual

Page 49

❏

3. Snap a nylon Faslink

™

onto both pushrods and cut off

the excess wire 1/16" above the Faslink. Caution: Wear

safety glasses whenever you cut wire! If you have

removed the pushrods to bend and cut the wire, unscrew

the clevis from the threaded end. Slide the pushrods back

into the guide tubes from the front and screw the clevises

back on.

❏

4. Remove the Faslink and temporarily inser t the

pushrods through the second from the outside hole in both

servo arms (this position may change upon setting the

throws). Reinstall the Faslinks to securely connect the

pushrods to the servos.

❏

5. Adjust the clevises so the elevator and rudder are

neutral with the radio on, the servos centered and the

pushrods connected.

❏

6. If you haven’t already done so, insert the nose wheel

steering pushrod into the Screw-Lock Pushrod Connector,

then center the nose wheel (remember the steering arm

should be angled forward). Install a 4-40 x 1/8" socket

head screw in the connector and tighten it down. Test the

steering. When the rudder moves to the right, the nose

wheel should also move to the right. Make sure the nose

gear steering arm does not contact the firewall when the

rudder stick is pushed fully to the left.

❏

7. Once you have finished setting up the nose wheel

steering, snap the nylon retainer on the connector under

the servo horn. Remove the 4-40 screw, then reinstall it

with thread locking compound and tighten it down. Cut off

the excess wire, leaving about 1/2" sticking out of the

connector.

❏

8. Snap the nylon ball link at the front of the throttle

pushrod onto the metal ball previously installed on the

carburetor arm. Pull the throttle control stick and trim lever

on your transmitter to the fully “back” or closed position.

❏

9. See the photo at step 4, then insert the pushrod

through the Screw-Lock Pushrod Connector if you haven’t

already done so. Install the horn on the servo so it points

toward the tail of the model at about a 30-degree angle as

shown.

❏

10. Pull the throttle pushrod toward the tail to fully close

the throttle. Install a 4-40 x 1/8" socket head screw in the

connector and tighten it. Move the throttle trim lever and

watch the carburetor to see if it opens slightly. If the servo

does not move (just sits there buzzing), flip the “Servo

Reversing Switch” on your transmitter. Open the throttle all

the way with the main control stick. If the throttle opens all

the way but the pushrod bends (or the servo buzzes), move

the connector one hole in toward the center of the servo

horn to decrease the amount of throw.

The goal is to get the engine to idle as slowly (but reliably)

as possible with the throttle stick pulled all the way back

and the trim switch in the mid to full open position. To shut

the engine off, simply pull back the trim switch. This

prevents you from inadvertently shutting the engine off

during flight.

❏

11. When the throttle works properly, install the nylon

retainer on the bottom of the screw lock connector to

secure it. Tighten the screw (with thread lock) and install

the servo horn screw. Cut off the extra wire, leaving about

1/2" behind the connector.

❏

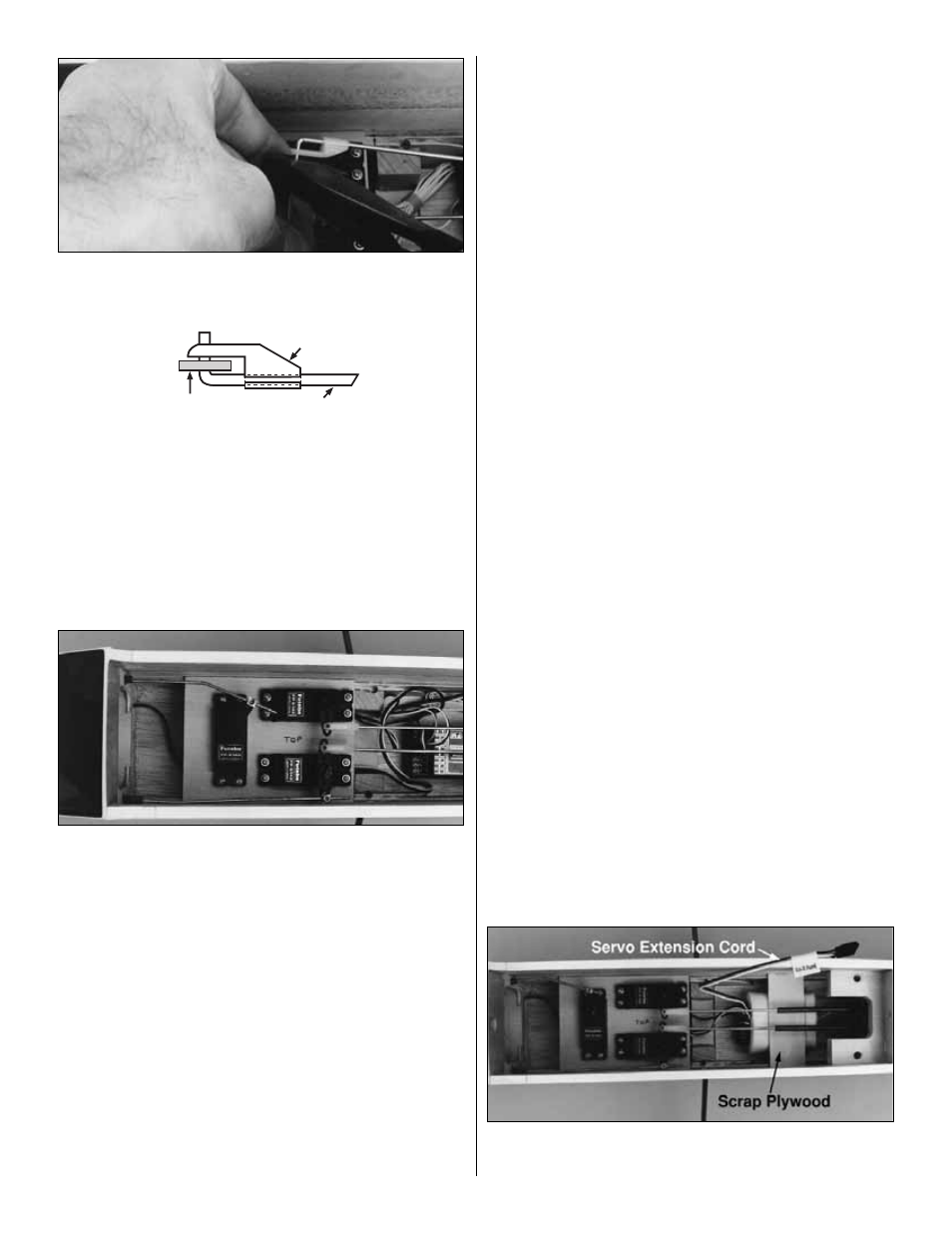

12. If you have a servo extension cord and are using

ailerons, plug it into to the receiver. A servo extension cord

will allow you to easily connect the aileron servo to the

receiver when you install the wing for each flying session.

❏

13. Wrap your receiver with 1/4" thick foam rubber.

Secure the foam with a couple of rubber bands or tape.

FasLink

2-56 (.074") Pushrod Wire

Servo Horn

49