Expert tip, Reinforce the wing – Great Planes PT-40 MkII Kit - GPMA0118 User Manual

Page 39

❏

1. Glue the fiberglass cloth to the center section of the

wing with thin CA. Start by tacking one end of the cloth to

Reinforce the Wing

EXPERT TIP

EXPERT TIP

EXPERT TIP

❏

3. Use your bar sander and 220-grit sandpaper to

bevel the sides and front of the top edges of the die-cut

1/16" plywood wing bolt plate (see the photo at step 4).

The side of the plate with the scored centerline is the

bottom.

❏

4. Drill a 1/16" hole through the punch marks in the

wing bolt plate.

Carefully “crack” the plate along its

scored centerline – try not to break it in two. The plate

should “bend away” from the scored line. Hint: Use your

#11 knife blade to lightly score an additional centerline

on the

top of the plate.

❏

5. With the wing on the fuselage and in alignment as

described in step 2, use medium CA to glue the wing bolt

plate to the top of the wing. Note: The aft edge of the

plate should be even with the trailing edge of the wing

and the sides of the plate should align with the sides of

the fuselage.

❏

6. While holding the wing securely in position, use a

#10 or a 13/64" drill bit to drill through the wing protector,

the wing, and the wing bolt plate in the fuselage. See the

Expert Tip below and try your best to keep the drill

perpendicular to the top surface of each wing half that

you drill through so the heads of the bolts will be even

with the wing when tightened down. IMPORTANT: Do

not allow the wing to shift during this procedure.

❏

7. Tap threads into the wing bolt plate with a 1/4-20 tap.

❏

8. Apply several drops of thin CA to the threads in the

wing bolt plate. Allow the CA to cure thoroughly, then

re-tap the threads.

❏

9. Test fit the wing to the fuselage with two nylon

1/4-20 wing bolts supplied in this kit.

39

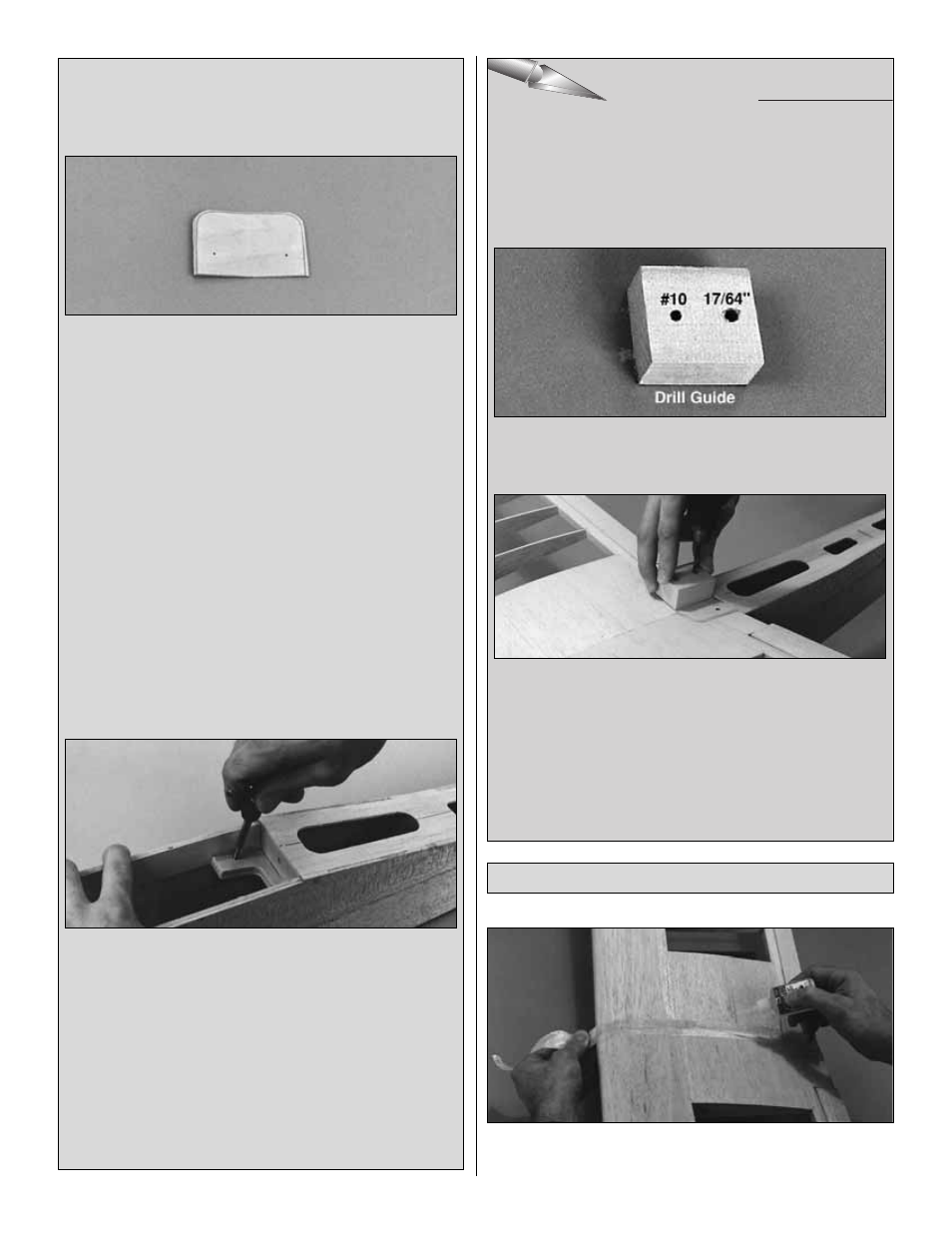

The most accurate way to make sure the holes you drill

for the wing bolts are perpendicular to the top surface of

the wing bolts are perpendicular to the top surface of the

wing is to make a drill guide. You’ll need a drill press so

if you don’t have one, beg or borrow (don’t steal)

a friend’s.

B. Position the drill guide and drill the #10 hole through

the wing and the wing bolt plate in the fuse. The drill

guide will accurately “steer” the drill toward the bolt plate.

Remove the wing and drill the clearance hole in the

wing with the 17/64" hole in the drill guide.

Now the holes on the wing and the bolt plate will be

perfectly aligned and the wing bolts will fit squarely on

the wing when tightened.

A. Use a drill press to drill a perpendicular #10 (or

13/64") hole and a 17/64" hole in an approximately 1" x

2" x 2" hard wood block.