Setting up shop – Great Planes PT-40 MkII Kit - GPMA0118 User Manual

Page 6

they'll need to do the best job possible. In some instances it

may not be clear exactly what the optional item is used for

so, where appropriate, we’ve listed the page number and/or

the step where that item is used. While you’re shopping,

you can reference the manual and decide ahead of time

whether not to make the additional purchase.

❏

6-Minute Epoxy (GPMR6045) see page 7

❏

1 oz. Thick CA- (GPMR6014) see page 7

❏

Epoxy Brushes (GPMR8060)

❏

Epoxy Mixing Sticks (GPMR8055, qty. 50)

❏

CA Debonder (GPMR6039)

❏

T-Pins (HCAR5100 - small, HCAR5200 - large)

❏

Hot Sock

™

(TOPR2175)

see page 41,

Cover the Structure

❏

Trim Seal Tool (TOPR2200)

see page 41, step B,

Expert Tip – Covering Technique

❏

Heat Gun (TOPR2000)

❏

Single Edge Razor Blades (HCAR0312, 100 qty.)

❏

Razor Plane (MASR1510)

see page 14,

step B, Expert Tip

❏

Z-Bend Pliers (HCAR2000)

see page 23, step 3

❏

Straightedge (Fourmost Non Slip FORR2149)

❏

3/16" dia. Antenna Tube (GPMQ3710 - or similar)

see page 18, step 9

❏

1/8" Brass Tube,

see page 38, step 17

❏

Denatured or Isopropyl Alcohol (for epoxy clean-up)

❏

Dremel

®

MultiPro

™

Tool or similar w/Sanding Drum,

Cutting Burr and Cut-off Wheel

If this is your first model there are a few necessary supplies

and tools that you should gather before going any further.

The single most important item that is required for any

modeling project is a flat work surface. The kitchen table is

generally not a good idea. A space where you can work,

leave stuff out, make a mess, spill glue and paint without

worry, and has adequate ventilation is ideal. Hey, the

garage sounds like a good place!

A workbench can be as simple as a solid flat table or made

from some two-by-fours and a solid core door. Hollow core

interior doors work fine, but the cheaper ones are prone

to warping.

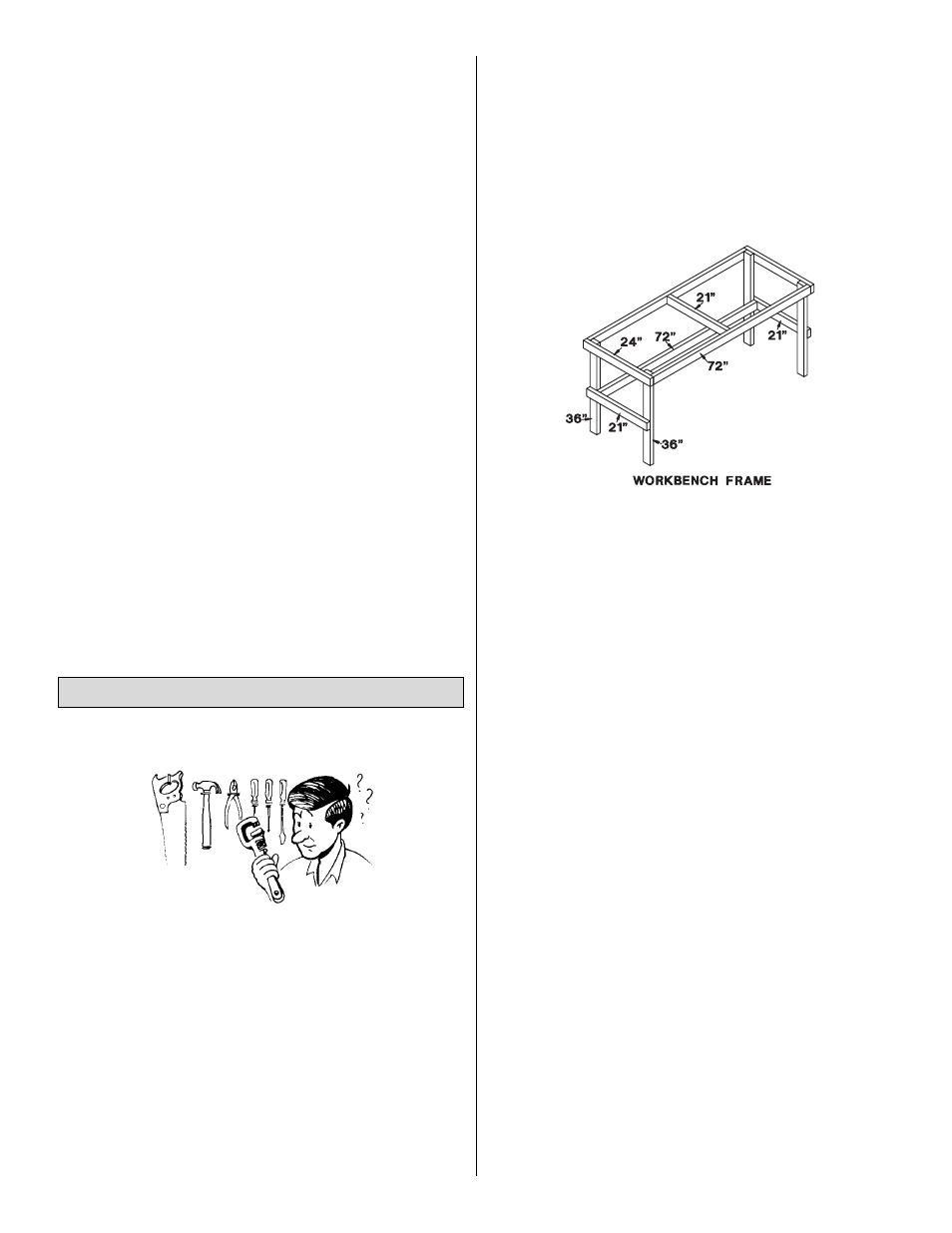

Here is a suggested approach for building an inexpensive

workbench. You will need (7) 6' - two-by-fours of good

quality pine or fir, a 30" x 82" door, some 16d (penny)

common nails, a handsaw and a hammer.

Assemble the workbench as follows:

1) Cut one two-by-four into three sections, two 24" long

and one 21" long.

2) Nail the 24" pieces to the two ends of two straight 6'

pieces to make the frame for the top. Nail the 21" piece

in between the two 6' pieces across the center of the frame.

3) Cut two two-by-fours in half to make four 36" legs. Nail

(or bolt) the four legs to the frame with the 2" side facing

the long sides of the frame.

4) Cut two 21" side rails from one of the remaining boards.

Nail the two boards to the sides of each pair of legs.

5) Nail the last 6' board to the front side of the back legs,

level with the two side pieces. One-by-three cross

braces may be nailed to the back legs for more rigidity.

6) Center the door on the frame and either glue or use

double sided foam back sticky tape to hold it in position.

You will need to cover your work surface with something

you can push pins into. The back side of a 2' x 4' sheet of

ceiling tile makes a great building surface, or if you want to

cover a larger area you can buy a 4' x 8' sheet of Celotex

insulation board from your local building supply store.

Most of the tools listed previously can probably be found

around the house. A few items like a razor saw, hobby knife,

sealing iron, heat gun and glues can be purchased at your

hobby dealer. As you get more involved with the hobby you

will probably want to add a few power tools such as a

Dremel tool, belt sander and a scroll saw, but in the case of

the PTs, everything you need has already been covered.

Setting Up Shop

6